Self-excited vibrator construction device

A technology of building construction and installation department, which is applied in the field of self-excited vibration building construction devices, which can solve the problems of high labor intensity, poor paste quality, and low paste efficiency, and achieve the effect of uniform percussion force and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

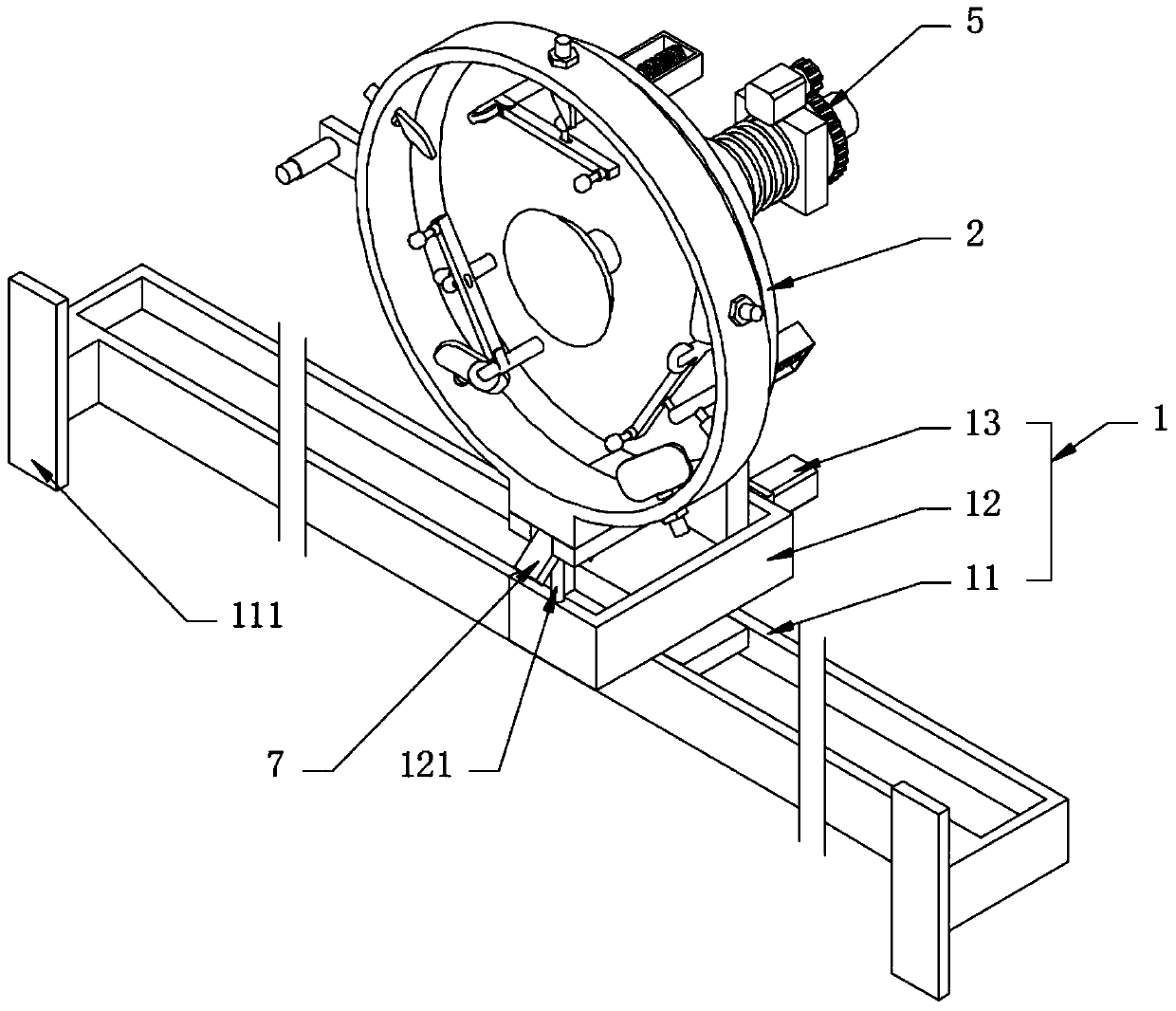

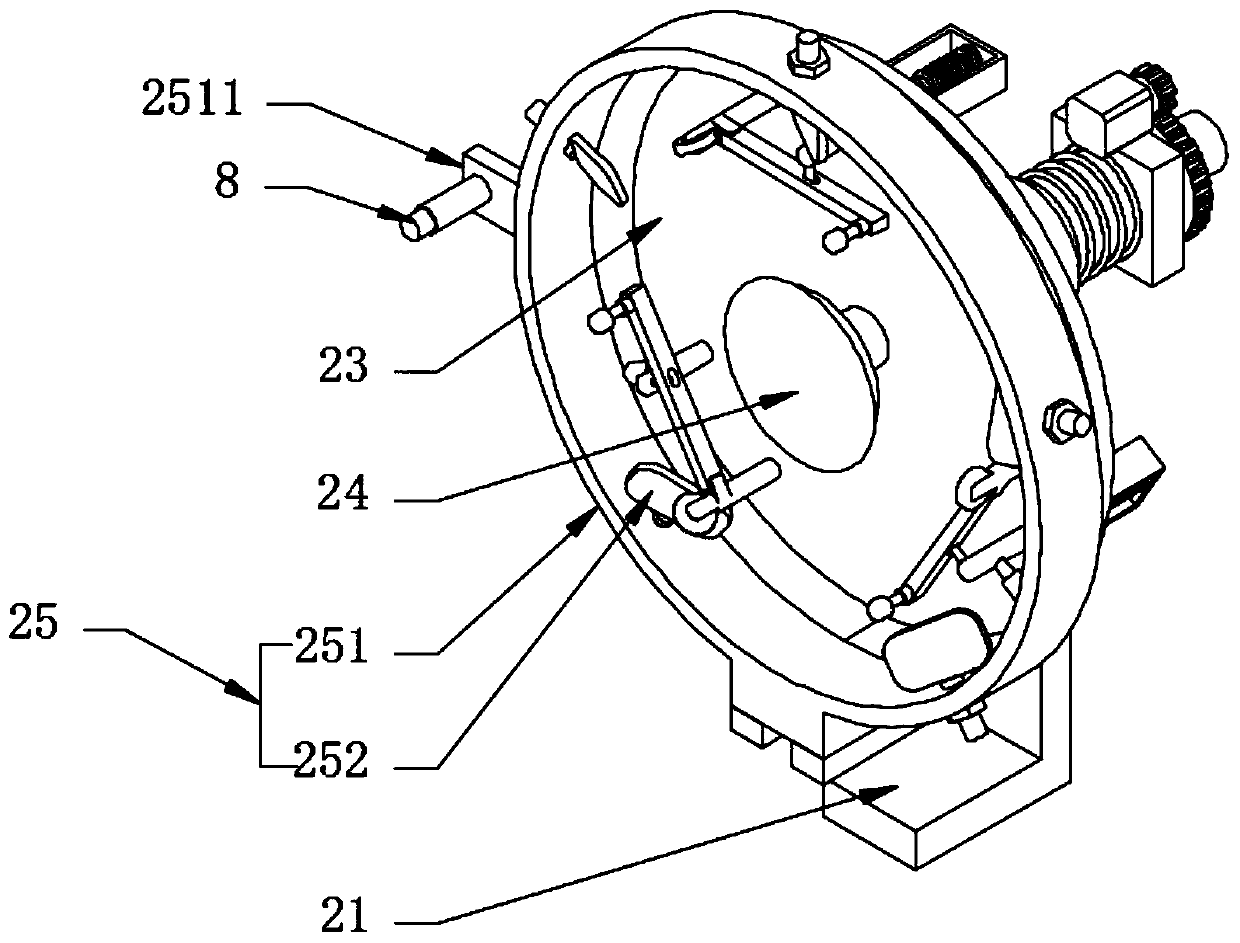

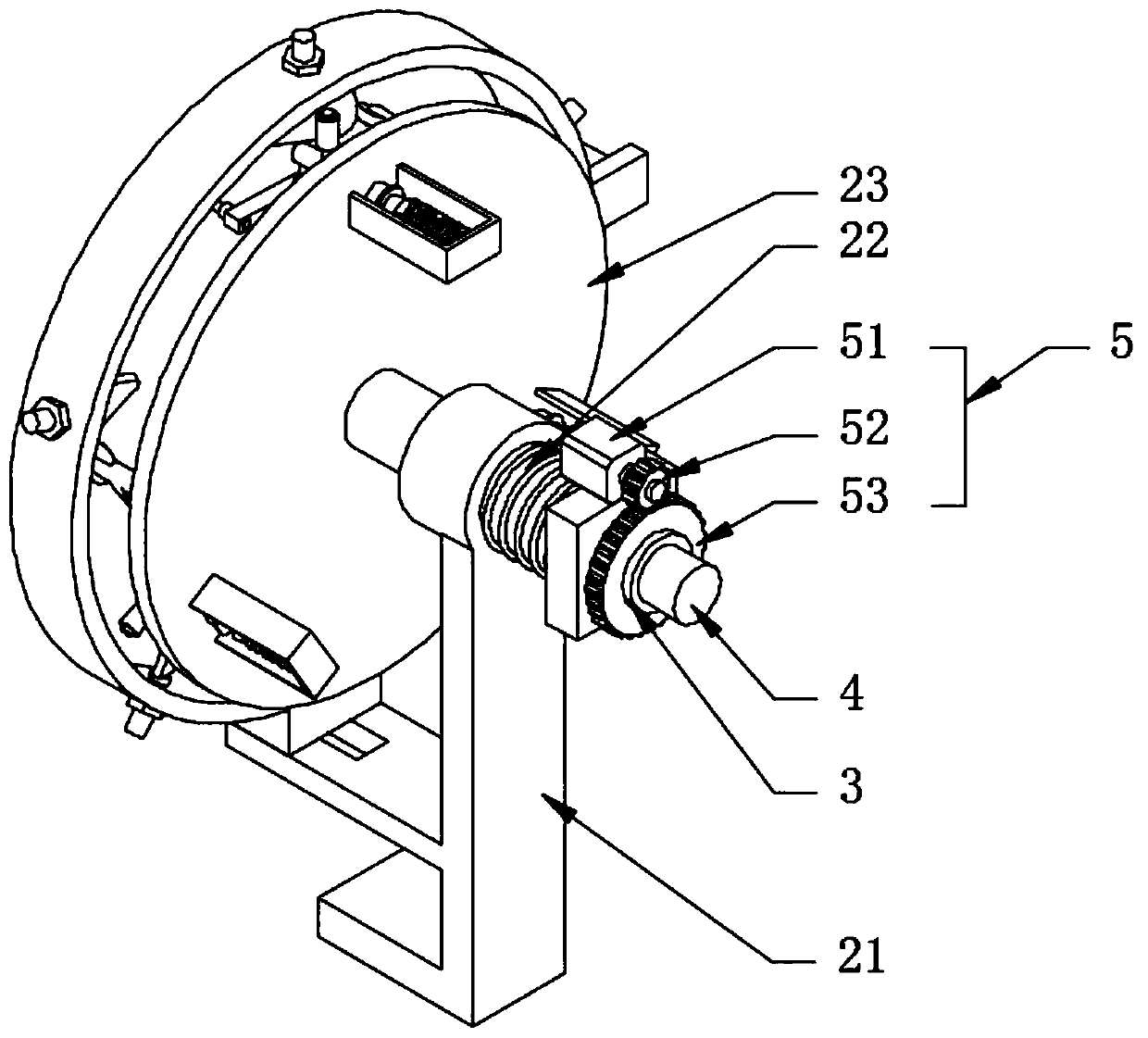

[0034] see Figure 1-4, a self-excited vibration building construction device, including a supporting sliding composite beam 1, a vibration mounting part 2 and a driving combination 5; the supporting sliding composite beam 1 includes a supporting beam 11, a bearing plate 12 slidingly fitted on the supporting beam 11 in the longitudinal direction and The electric telescopic rod 13 arranged on one end of the bearing plate 12, the front side of the support beam 11 and the two ends are provided with a T-shaped mounting plate 111, the support beam 11 is installed on the high-altitude outer wall through the T-shaped mounting plate 111, and the support beam 11 is Horizontal distribution; the vibration installation part 2 includes a support plate 21, a guide sleeve 22, a vibration turntable group 23, a suction cup 24 and a bump positioning ring 25, and the top of the support plate 21 is elastically slid with the guide sleeve 22; the bottom of the support plate 21 and the bearing plate ...

Embodiment 2

[0036] see Figure 5 The difference from Embodiment 1 is that one end of the slope plate 252 is fixedly provided with a screw rod 2521 that is threaded through the annular plate 251, and a locking nut 6 is screwed on the screw rod 2521, and the driving column 234 can be adjusted by adjusting the locking nut 6. Knocking amplitude; on the driving column 234 and on one side of the limit block 2341, an adjusting nut 9 is screwed, and the compression range of the driving spring 235 can be adjusted by rotating the adjusting nut 9, and then the knocking intensity of the driving column 234 can be adjusted.

Embodiment 3

[0038] see Image 6 , and the difference from Embodiment 1 is that one side of the support plate 21 and the lower part of the annular plate 251 are fixedly provided with a supporting plate 211, and one end of the supporting plate 211 is provided with a limit gap 2111, and the angle plate 7 is rotatably connected in the limit gap 2111 , the support plate 12 is fixedly provided with the support lever 121 used in conjunction with the corner plate 7, that is to say, when the outer wall panel and the suction cup 24 need to be docked, firstly the entire support plate 21 is under the control of the electric telescopic rod 13 Place it at the rear, at this time, support the lever 121 to move one side plate of the angle plate 7 to be located at the front side of the ring plate 251, at this time, just place the outer wall panel on the angle plate 7, and then slide the connecting shaft 4 to make the suction cup 24 and absorb and position the exterior wall panels, thereby facilitating the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com