Optical film process equipment and its guiding device

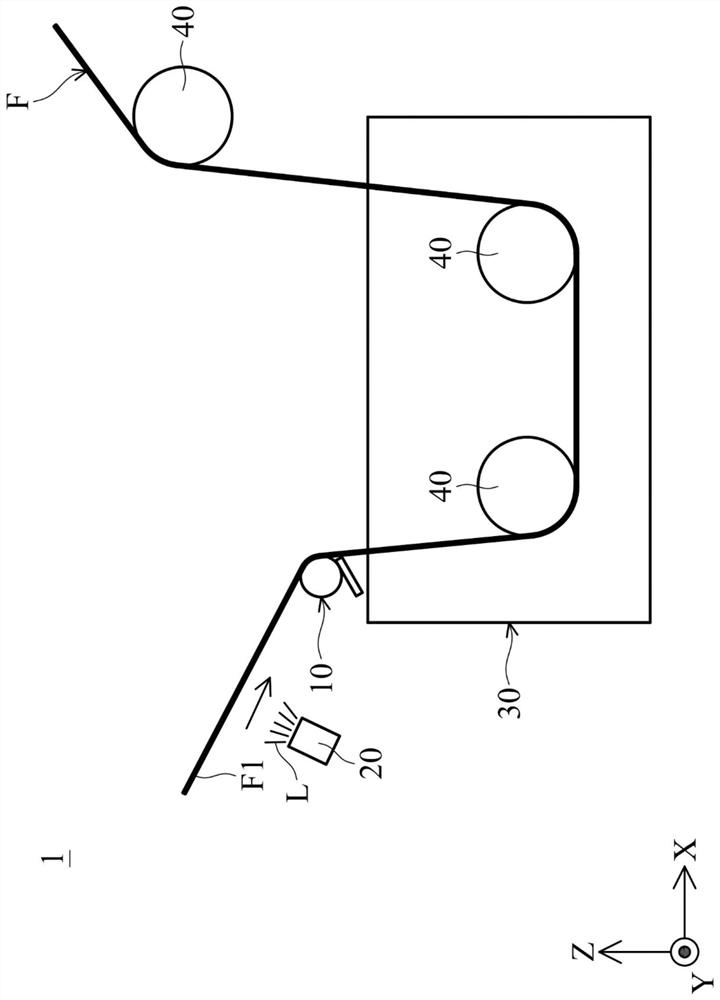

A technology of a diversion device and process equipment, which is applied in optics, optical components, transportation and packaging, etc., can solve the problems of water marks on the film surface of the optical film in the process tank, uneven dyeing of the optical film, and splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

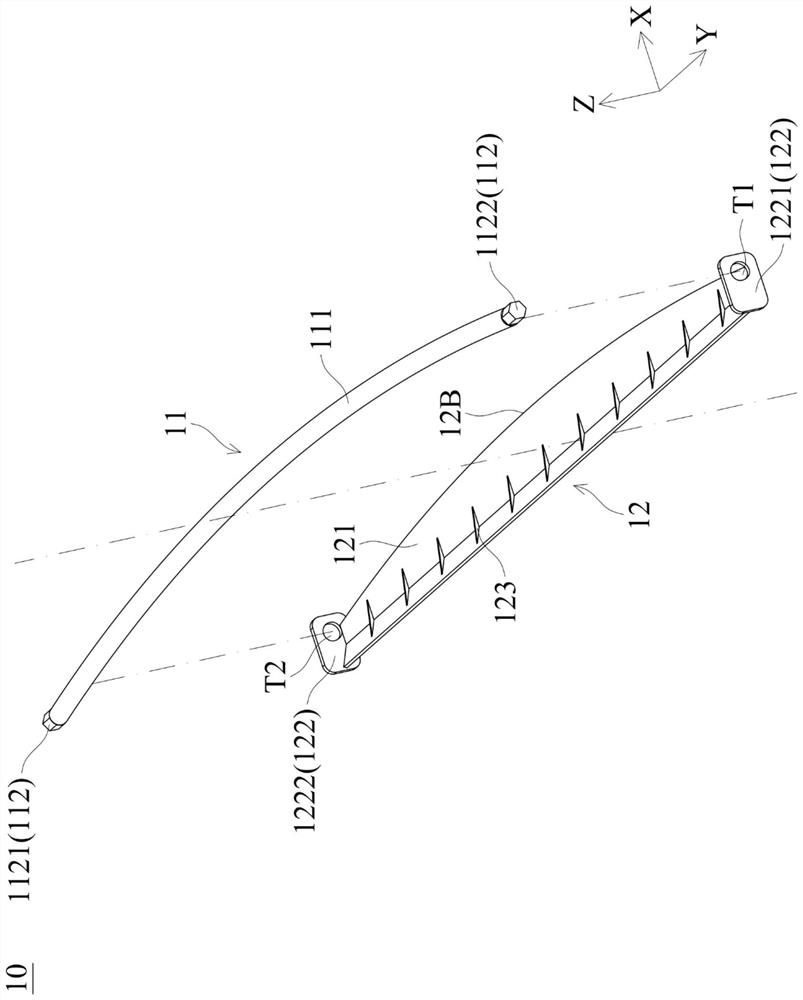

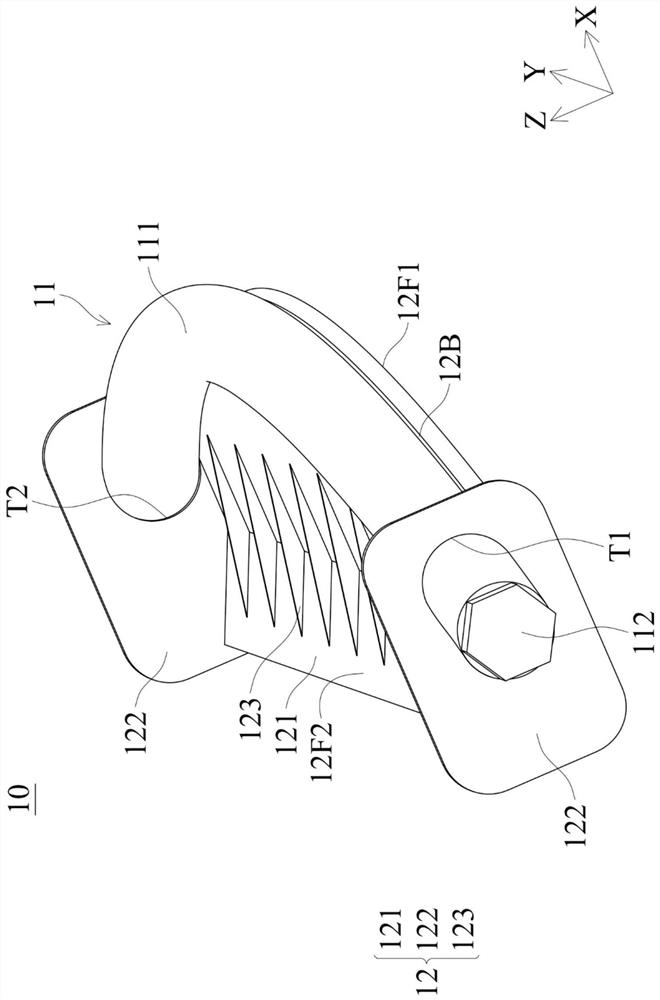

Embodiment Construction

[0046] Many different implementation methods or examples are disclosed below to implement different features of the provided subject matter, and specific elements and embodiments of their arrangement are described below to illustrate the disclosure. Of course, these examples are for illustration only, and should not limit the scope of the present disclosure. For example, in the description, it is mentioned that the first feature part is formed on the second feature part, which includes the embodiment that the first feature part and the second feature part are in direct contact, and also includes the embodiment where the first feature part and the second feature part are in direct contact. Embodiments where there are other features between the two feature parts, that is, the first feature part is not in direct contact with the second feature part.

[0047] Other areas of applicability for the device of the present invention will become apparent from the detailed description pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com