Financial voucher arranging and binding device

A voucher and financial technology, applied in the field of financial voucher sorting and binding devices, can solve the problems of voucher dislocation, unguaranteed binding quality, troublesome operation, etc., and achieve the effect of ensuring binding effect, realizing automatic operation, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

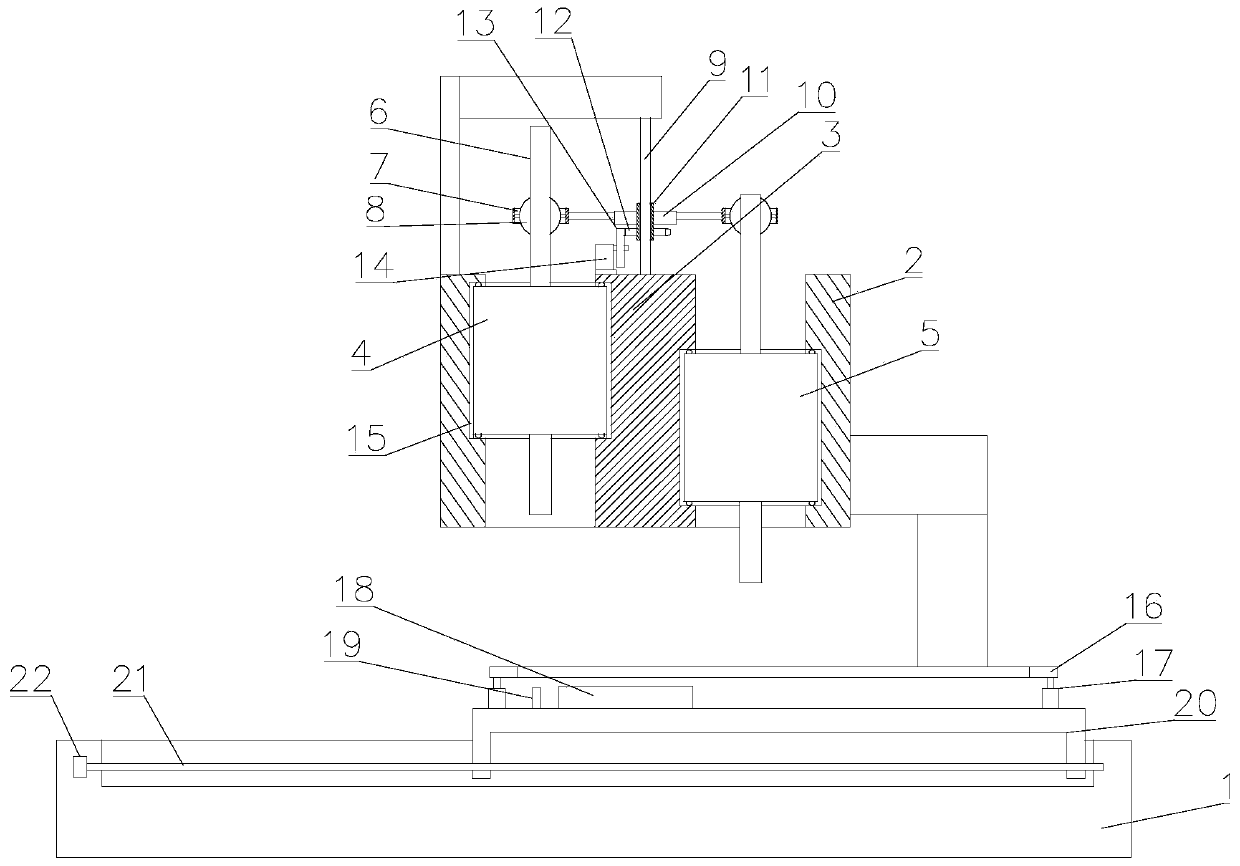

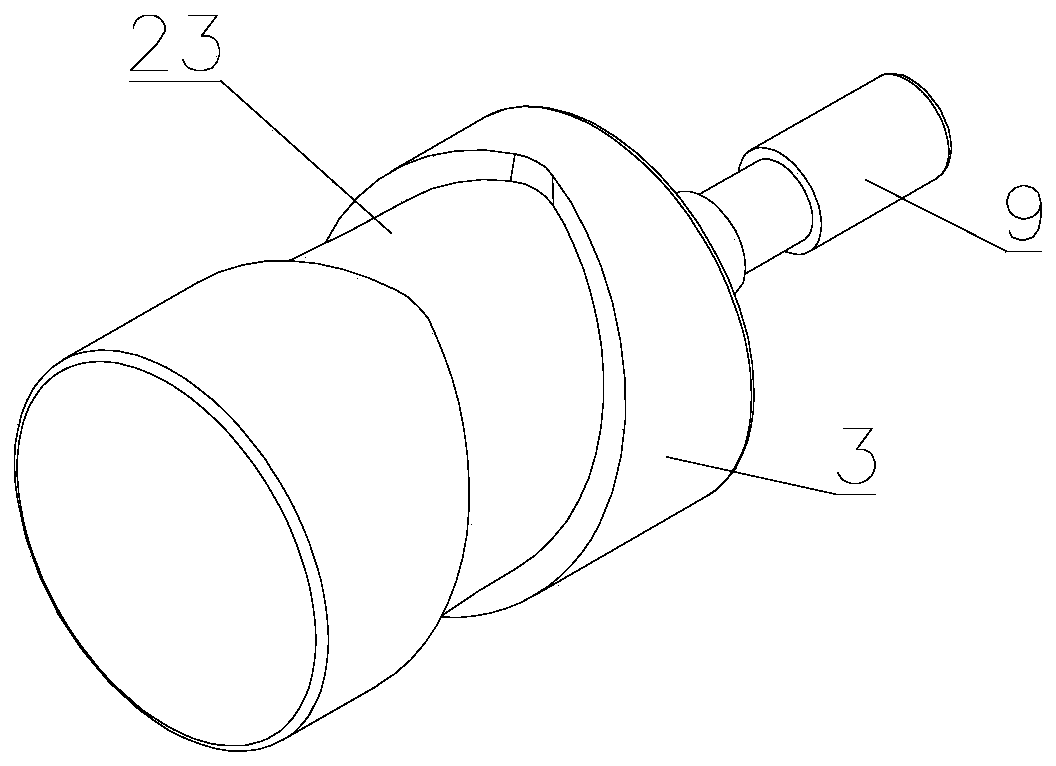

[0028] see Figure 1~4 , in Embodiment 1 of the present invention, a financial voucher sorting and binding device includes a base 1 and a cylinder 2 fixedly installed on the base 1, the inside of the cylinder 2 is fixedly provided with an intermediate shaft 3, and the outer side of the intermediate shaft 3 and The inside of the cylinder 2 is respectively provided with a B slideway 23 and an A slideway 15, and the two ends of the drilling assembly 4 and the hot-melt binding assembly 5 are respectively slidably installed on the B slideway 23 and the A slideway 15, and the B slideway 23 and A slideway 15 are provided with a high position and a low position, and the intermediate shaft 3 is provided with a device to drive the hot-melt binding assembly 5 and the drilling assembly 4 to rotate, so that the hot-melt binding assembly 5 and the drilling assembly 4 are between the high and low positions Change the position, when the drilling assembly 4 is at a low position, the voucher pl...

Embodiment 2

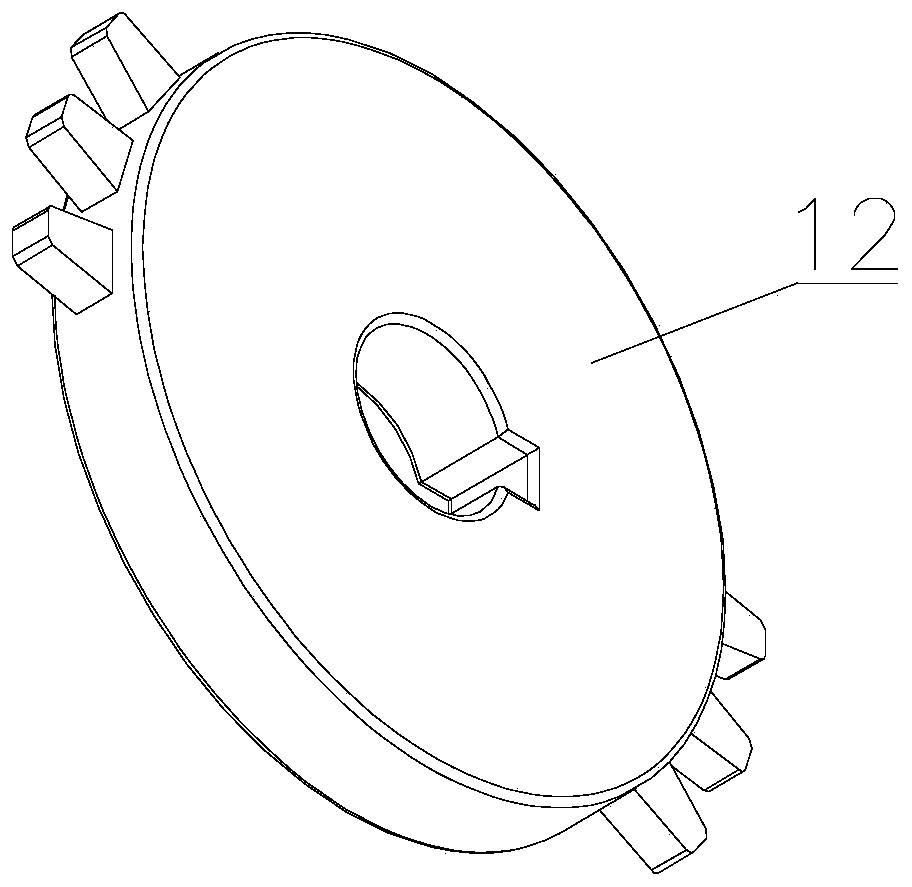

[0030] see Figure 1~4 The main difference between this embodiment 2 and embodiment 1 is that the intermittent drive mechanism includes an incomplete full gear 12 fixedly sleeved on the outside of the sleeve 11 and a disc wheel 13 cooperating with the incomplete full gear 12. Both sides of the complete full gear 12 are respectively provided with meshing tooth sets, and the disc wheel 13 is provided with a mating tooth set that intermittently meshes with the meshing teeth on the incomplete full gear 12, because the mating teeth only engage with one side every time they rotate. The meshing tooth set is meshed, and then the hot-melt binding assembly 5 and the drilling assembly 4 are rotated 180° respectively;

[0031] The disc wheel 13 is disc-shaped, and the upper edge of the convex edge of the disc wheel 13 is set in conjunction with the tooth set.

[0032] The angle difference between the high position and the low position of both the A slideway 15 and the B slideway 23 is 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com