A sound-absorbing board scraping device for engineering construction

A technology for construction and sound-absorbing panels, applied in metal processing, etc., can solve the problems of low work efficiency, labor-consuming, long-time, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

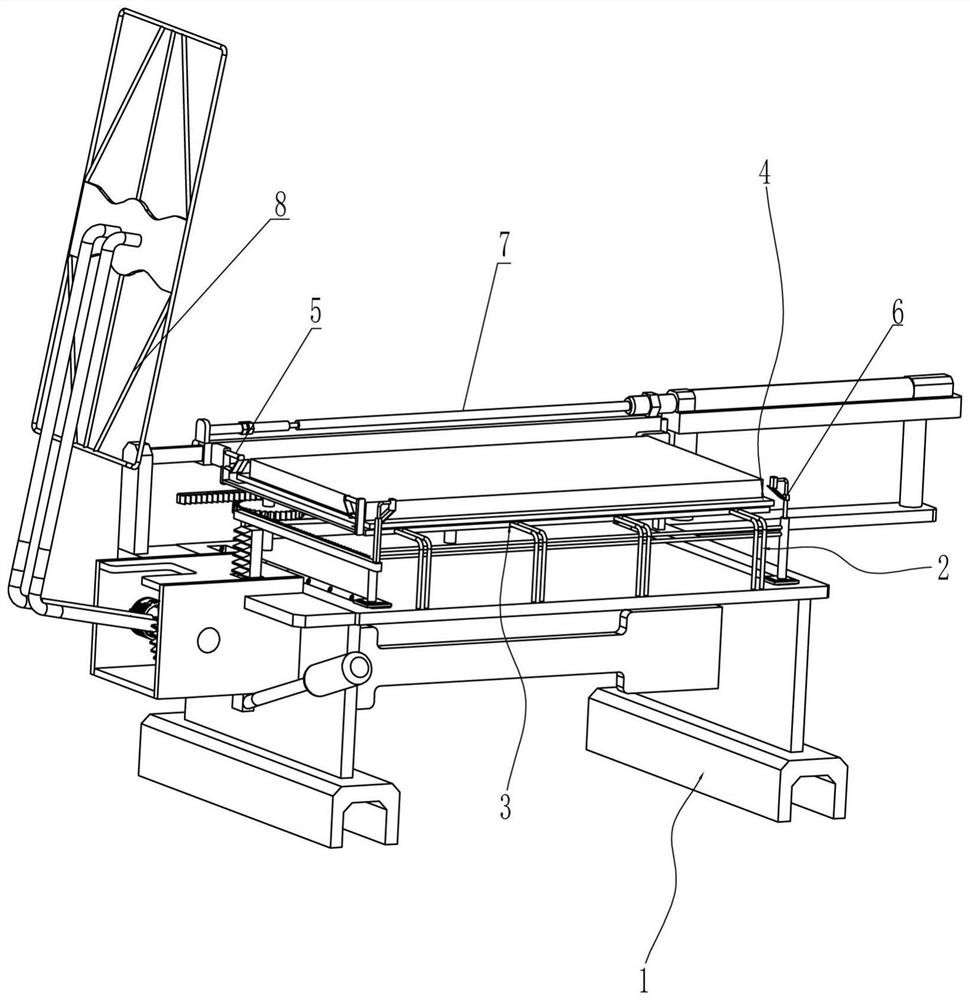

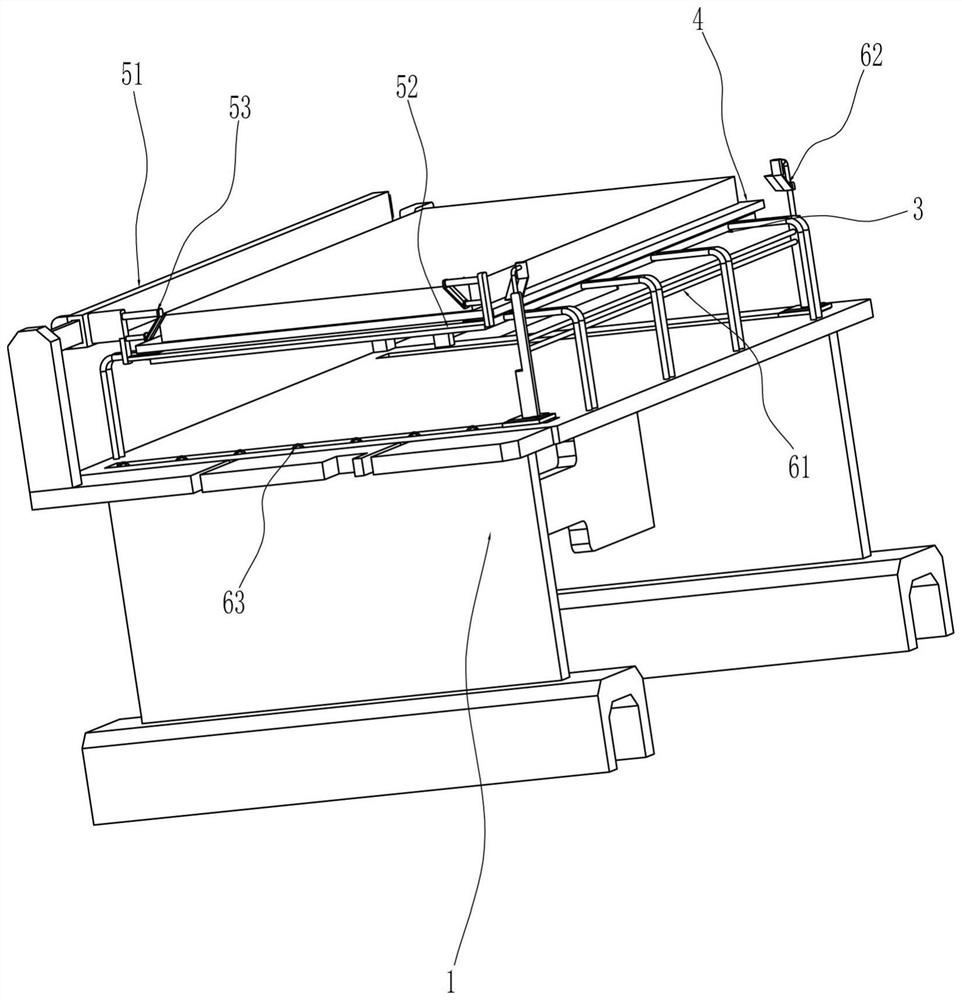

[0025] A device for scraping edges and corners of sound-absorbing panels for engineering buildings, such as Figure 1-2 As shown, it includes a mounting base 1, a connecting frame 2, a first fixing plate 3 and a second fixing plate 4, the top of the mounting base 1 is connected to the front and rear sides of the connecting frame 2, and the connecting frames 2 on both sides are connected to the first The fixed plate 3 is connected with the second fixed plate 4 at the rear of the top right side of the mounting base 1, and the second fixed plate 4 is located above the first fixed plate 3, and also includes a cross-cutting assembly 5 and a longitudinal cutting assembly 6, on the mounting base 1 A transverse cutting assembly 5 and a vertical cutting assembly 6 are provided.

[0026] The cross-cut assembly 5 includes a slide rail 51, a slide plate 52 and a first cutting knife 53, the rear side of the top of the mount 1 is connected with a slide rail 51, and the slide rail 51 is slid...

Embodiment 2

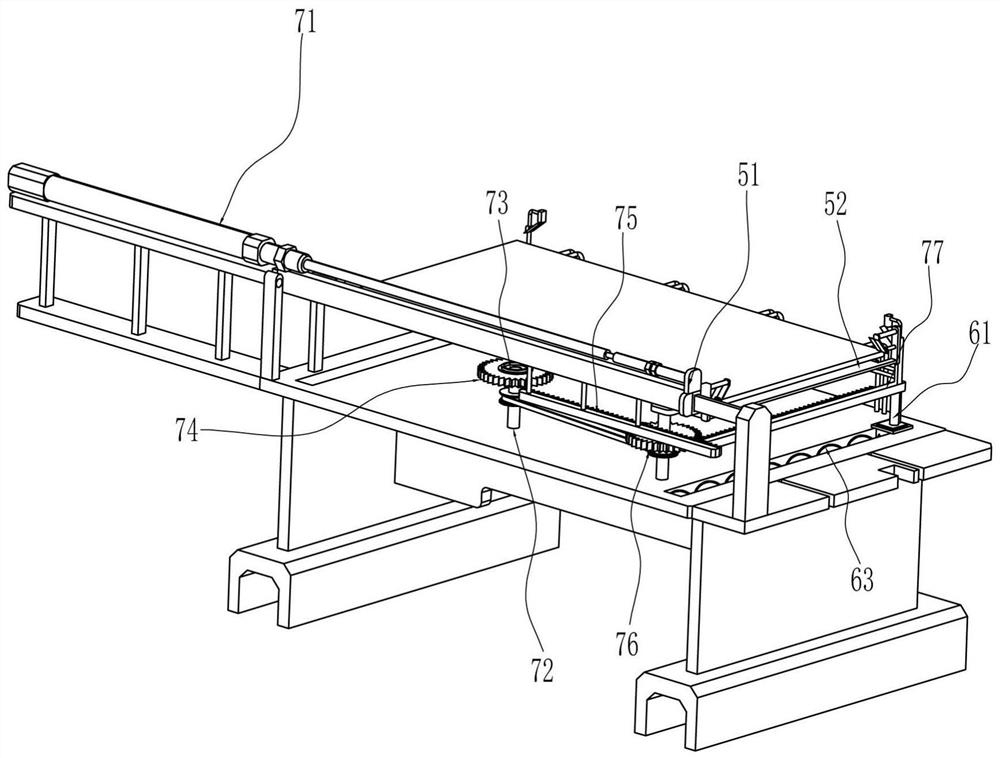

[0030] On the basis of Example 1, such as image 3 As shown, a driving assembly 7 is also included, and the driving assembly 7 includes a cylinder 71, a rotating shaft 72, a one-way clutch 73, a driving gear 74, a driving rack 75, a transmission gear 76 and a transmission rack 77, and the rear side of the top of the mounting base 1 Cylinder 71 is installed, and the telescoping link of cylinder 71 is connected with sliding plate 52, and the middle rotation type of mounting base 1 top rear side is connected with rotating shaft 72, is connected with one-way clutch 73 on the rotating shaft 72, is connected with drive gear 74 on the one-way clutch 73 , the bottom of the sliding plate 52 is connected with a driving rack 75, the driving rack 75 will mesh with the driving gear 74, and the rear part of the left side of the top of the mounting seat 1 is connected with a transmission gear 76 in a rotational manner, and the transmission gear 76 and the driving gear 74 pass through a belt a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com