Bottle cap riveting equipment

A bottle cap and riveting technology, which is applied in metal processing equipment, capping, feeding devices, etc., can solve problems such as unguaranteed product quality, substandard product quality, and hidden safety hazards, and achieves small footprint, convenient operation, and The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

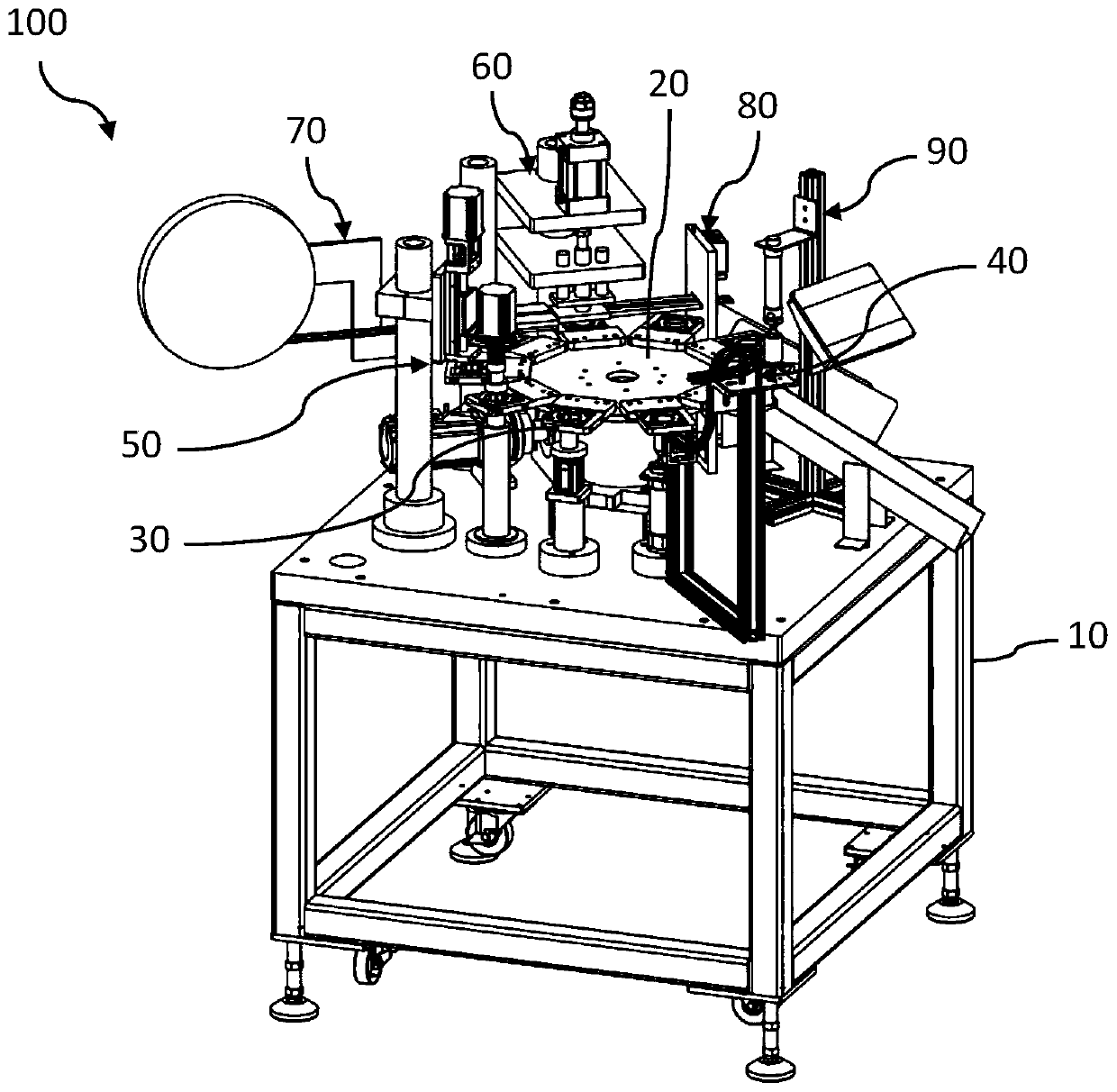

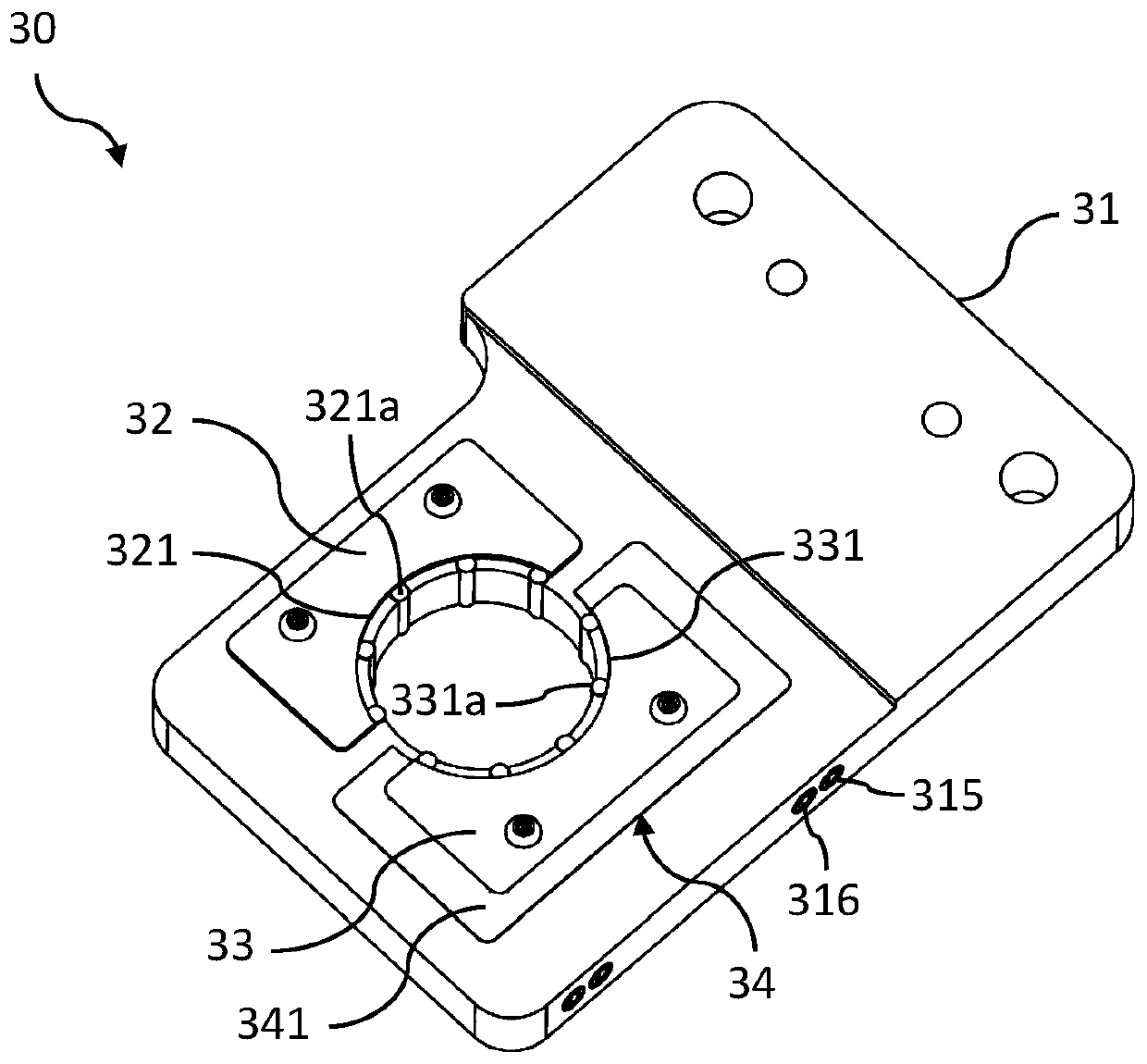

[0035] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, characteristics and effects of the bottle cap riveting equipment of the present invention.

[0036]

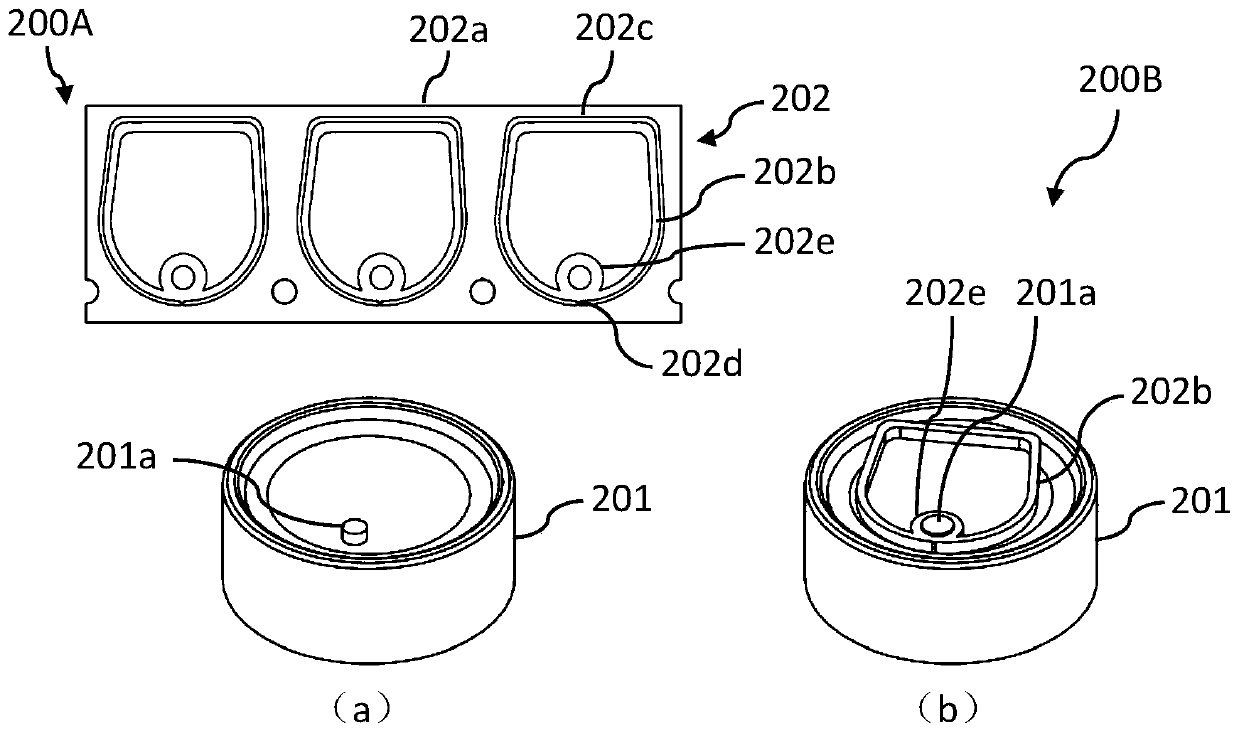

[0037] figure 1 It is a structural schematic diagram of a semi-finished bottle cap and a finished bottle cap in an embodiment of the present invention.

[0038] Such as figure 1 As shown, the bottle cap semi-finished product 200A includes a bottle cap body 201 and a pull ring belt 202 .

[0039] The bottle cap main body 201 is in the shape of a cylinder, and the edge of its top wall is provided with a riveting protrusion 201a.

[0040] The pull-tab strap 202 has a strap body 202a and a plurality of pull-tabs 202b.

[0041] The strap main body 202a is provided with a plurality of pull ring strap openings 202c arranged in sequence along its length direction and respectively ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com