Mould used for stretching long cone body

A mold and cone technology, which is applied in the field of machinery manufacturing equipment, can solve the problems that the thin-walled cone barrel cannot be stretched, the flange of the stretched part is wrinkled, and the stretched part has a bulge, etc., so as to achieve good appearance and good impact The effect of uniform force and guaranteed forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

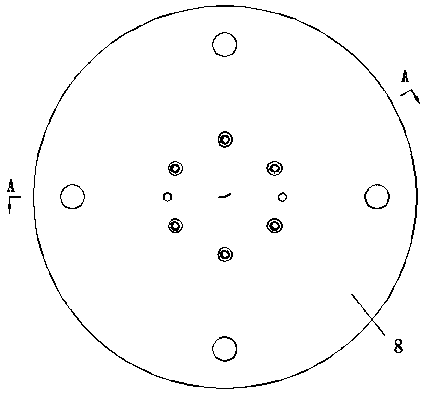

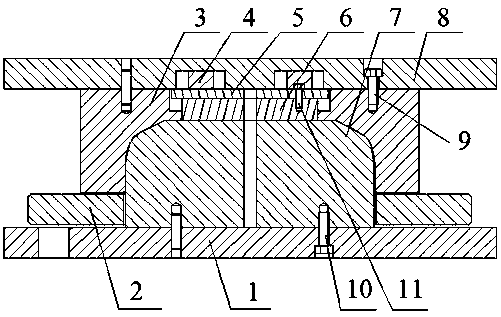

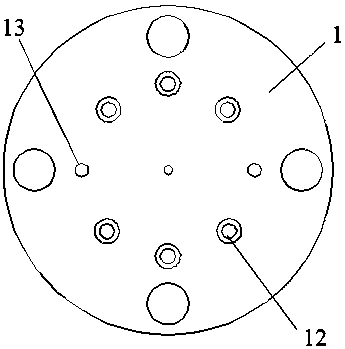

[0025] Embodiment 1: as attached Figure 1-10 Shown, a kind of mold that is used for stretching elongated tapered barrel, it comprises lower template 1, upper cover plate 8, die 3 and punch 7, and described punch 7 is connected to the bottom of lower template 1 by screw one 10 Above, the die 3 is covered on the top of the punch 7, and the upper cover plate 8 is connected to the top of the punch 3 by screw 2 9, and the outer lower part of the punch 7 is also provided with a blank holder 2, and the blank holder 2 Located below the die 3. The lower template 1 is a circular plate-like structure, and the lower template 1 is provided with a positioning hole 13 and a screw hole 12, and the screw 10 is located in the screw hole 12. Lower template 1 is used for supporting and fixing punch 7 usefulness. The blank holder 2 is a circular plate-shaped structure, and the gap between the blank holder 2 and the punch 7 is a long tapered cylinder wall. There is also a gap between the blank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com