Coating and rolling device for battery production

A coating roller and battery technology, applied to the surface coating liquid device, spray device, cleaning method using tools, etc., can solve the problems of low production efficiency, easy to be contaminated with dust, poor controllability of product quality, etc., to achieve Improve production efficiency, ensure coating effect, and ensure drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

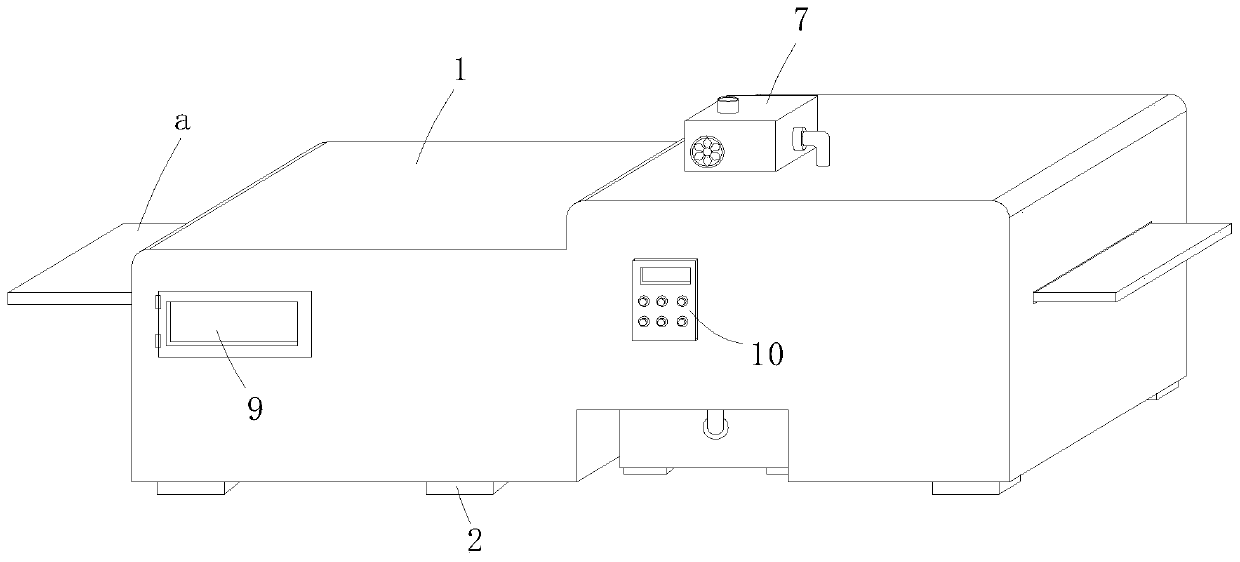

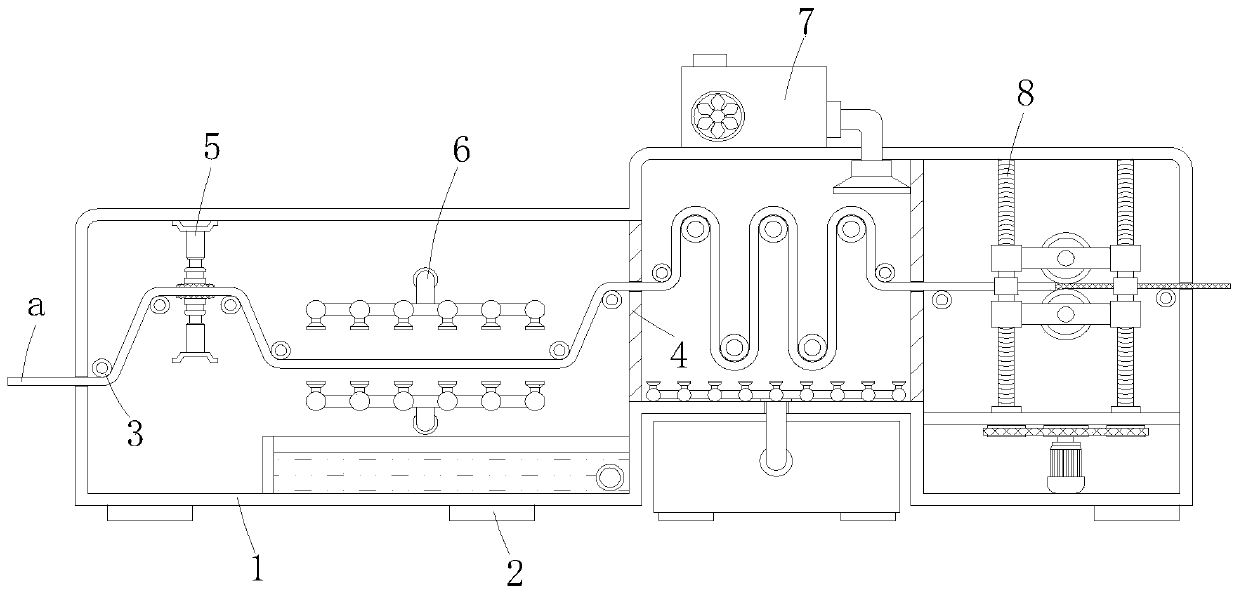

[0036] A coating rolling device for battery production, comprising a device housing 1 and a plurality of support feet 2 installed at the lower end of the device housing 1, the opposite side walls of the device housing 1 are respectively provided with inlets for the input of current collector a The feed port and the discharge port for the output of the current collector a, and a plurality of rotating rollers 3 for the transmission and tension of the current collector a are installed on the inner wall of the device housing 1, so that the current collector a passes through the inner cavity of the device housing 1 It can be adapted to various processing mechanisms and processed into pole pieces suitable for battery production. It can be understood that part of the rotating roller 3 is equipped with a driving device, and the driving device can be a transmission motor to ensure that the current collector a There are two partition plates 4 installed vertically in the inner cavity of t...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is that, as figure 2 with 3 As shown, the upstream of the coating mechanism 6 is also provided with a dust removal mechanism 5, and the dust removal mechanism 5 is arranged in the coating chamber. The dust removal mechanism 5 includes a dust removal wiper 51 symmetrically attached to both sides of the collector a. The cloth 51 is detachably fixedly installed on the wiper seat 52, and the wiper seat 52 is fixedly installed on the telescopic end of the cylinder 53, the cylinder 53 is fixed on the installation rod 54, and the two installation rods 54 are fixedly installed in the coating chamber On the inner wall of the two dust removal cloths 51, the upper and lower sides of the current collector a are wiped, dust and impurities are removed, and the subsequent coating effect is ensured. Combined with the drive of the cylinder 53, dust removal and wiping can be performed according to the thickness of the current colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com