force sensor

A technology of force sensor and sensing part, applied in the field of sensors, can solve the problems of increasing the manufacturing cost of sensors, easy wear and tear, and insufficient supporting force of sensing elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

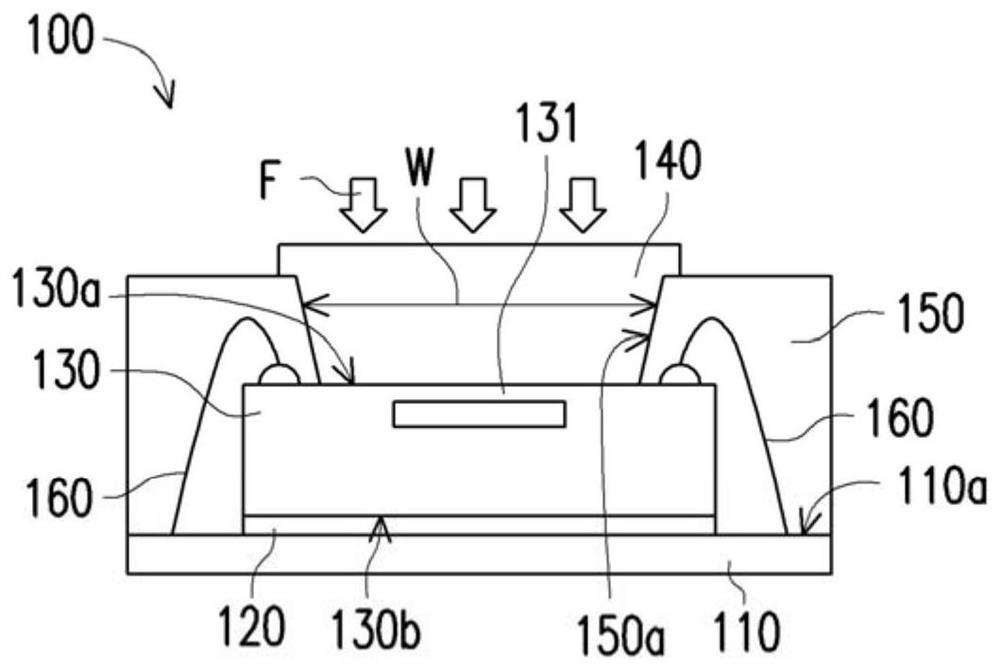

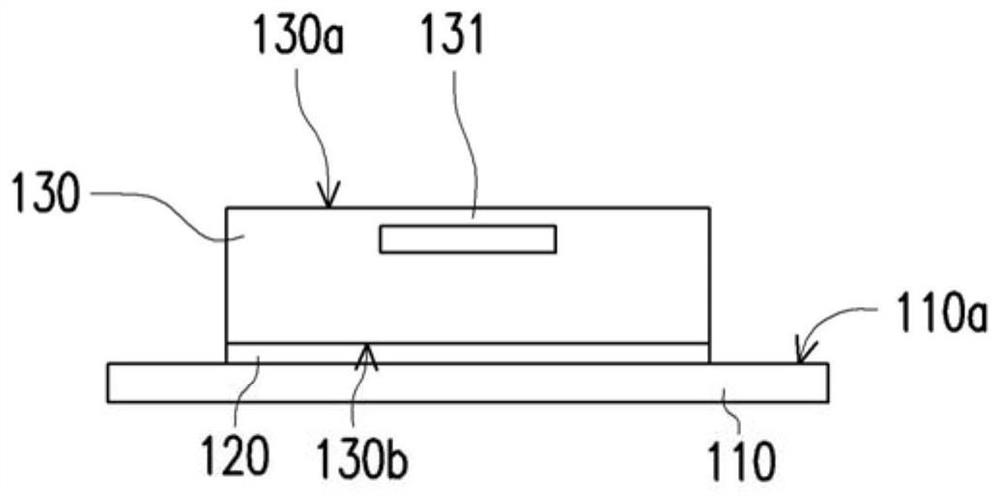

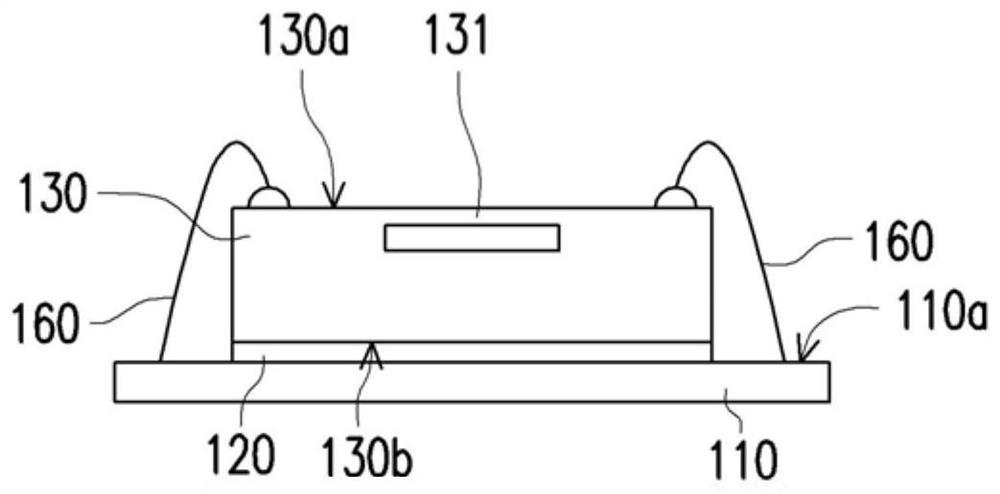

[0041] figure 1 is a cross-sectional view of a force sensor according to an embodiment of the present invention. Please refer to figure 1 The force sensor 100 of this embodiment is, for example, a microelectromechanical force sensor and includes a circuit board 110 , a bonding layer 120 , a sensing element 130 , a first glue 140 , a second glue 150 and at least one welding wire 160 . The sensing element 130 has an opposite top surface 130 a and a bottom surface 130 b and has a sensing portion 131 located on the top surface 130 a. The sensing element 130 may be a piezoresistive sensing element, a capacitive sensing element or other suitable sensing elements, and the invention is not limited thereto.

[0042] The first glue 140 is disposed on the top surface 130 a of the sensing element and covers the sensing portion 131 . The sensing part 131 is adapted to cause the sensing element 130 to generate a sensing signal through the external force F transmitted from the first glue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com