Construction machinery lubricant filling machine

A technology of construction machinery and lubricants, which is applied in the direction of engine lubrication, mechanical equipment, and lubricating parts, etc. It can solve the problems of enhanced fluidity, reduced mechanical lubrication effect, and poor temperature emission effect of filling machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

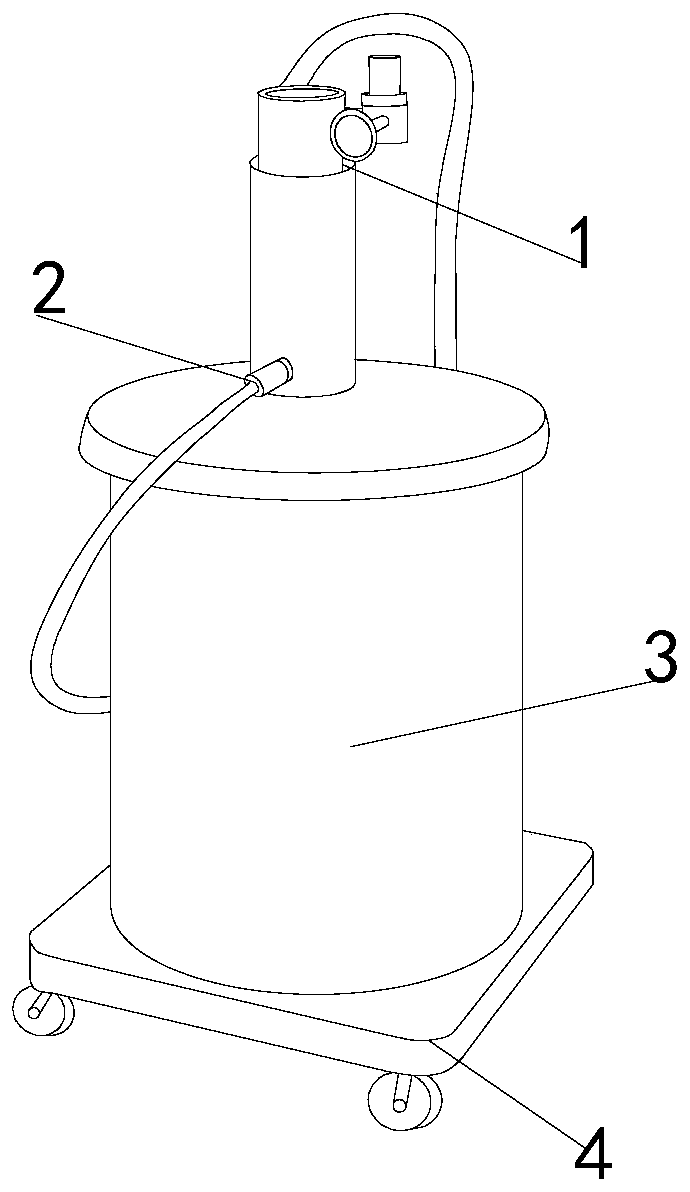

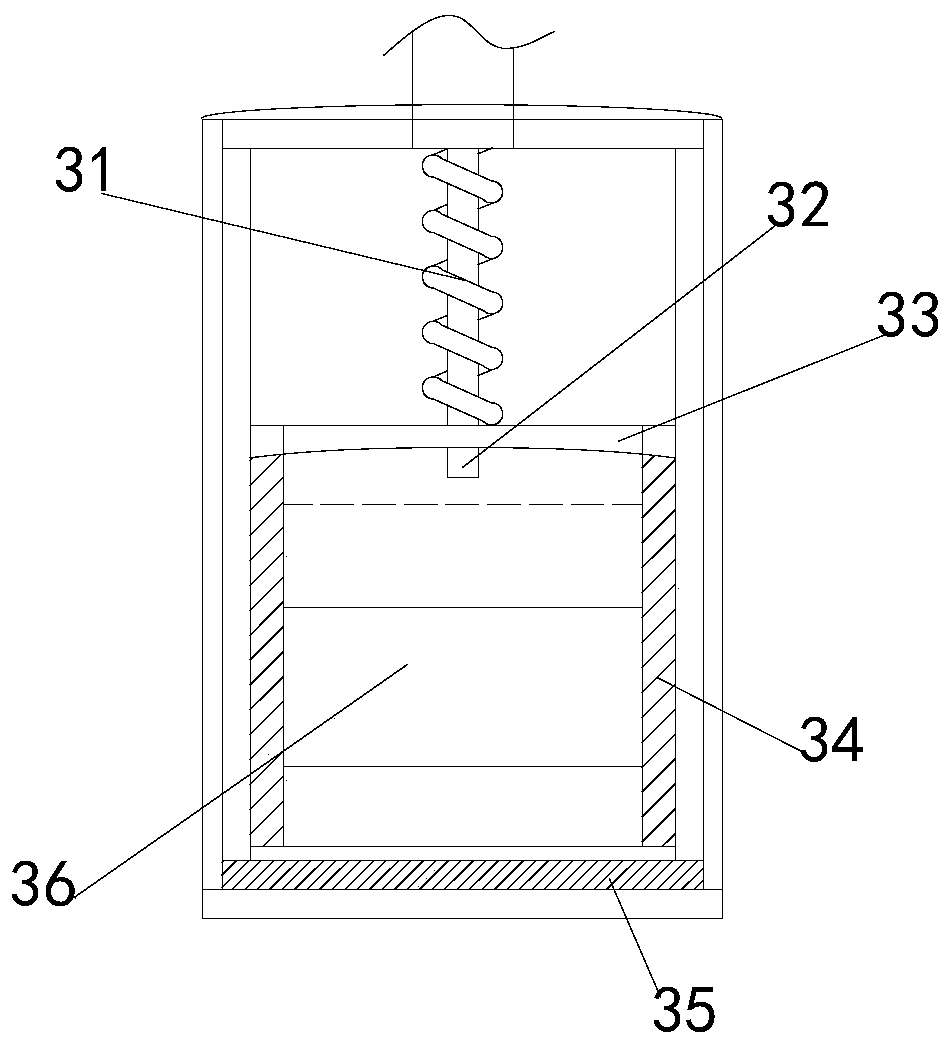

[0025] like Figure 1-Figure 5 Shown:

[0026] The present invention is a lubricant filling machine for construction machinery. Its structure includes a hydraulic pump 1, a spray pipe 2, a storage tank 3, and a moving plate 4. The spray pipe 2 is embedded and installed on the side of the hydraulic pump 1. The pump 1 is welded on the upper end of the storage tank 3, the moving plate 4 is fixedly installed on the lower end of the storage tank 3, the center point of the hydraulic pump 1 and the storage tank 3 is located on the same axis, and the storage tank 3 It is composed of an elastic rod 31, an absorber 32, a compression plate 33, a storage box 34, a cooling mechanism 35, and a storage box 36. The absorber 32 and the elastic rod 31 are integrally formed, and the compression plate 33 and the absorber 32 The storage box 36 and the placement box 34 are integrated structures, the cooling mechanism 35 is attached to the lower end of the placement box 34, the compression plate 33...

Embodiment 2

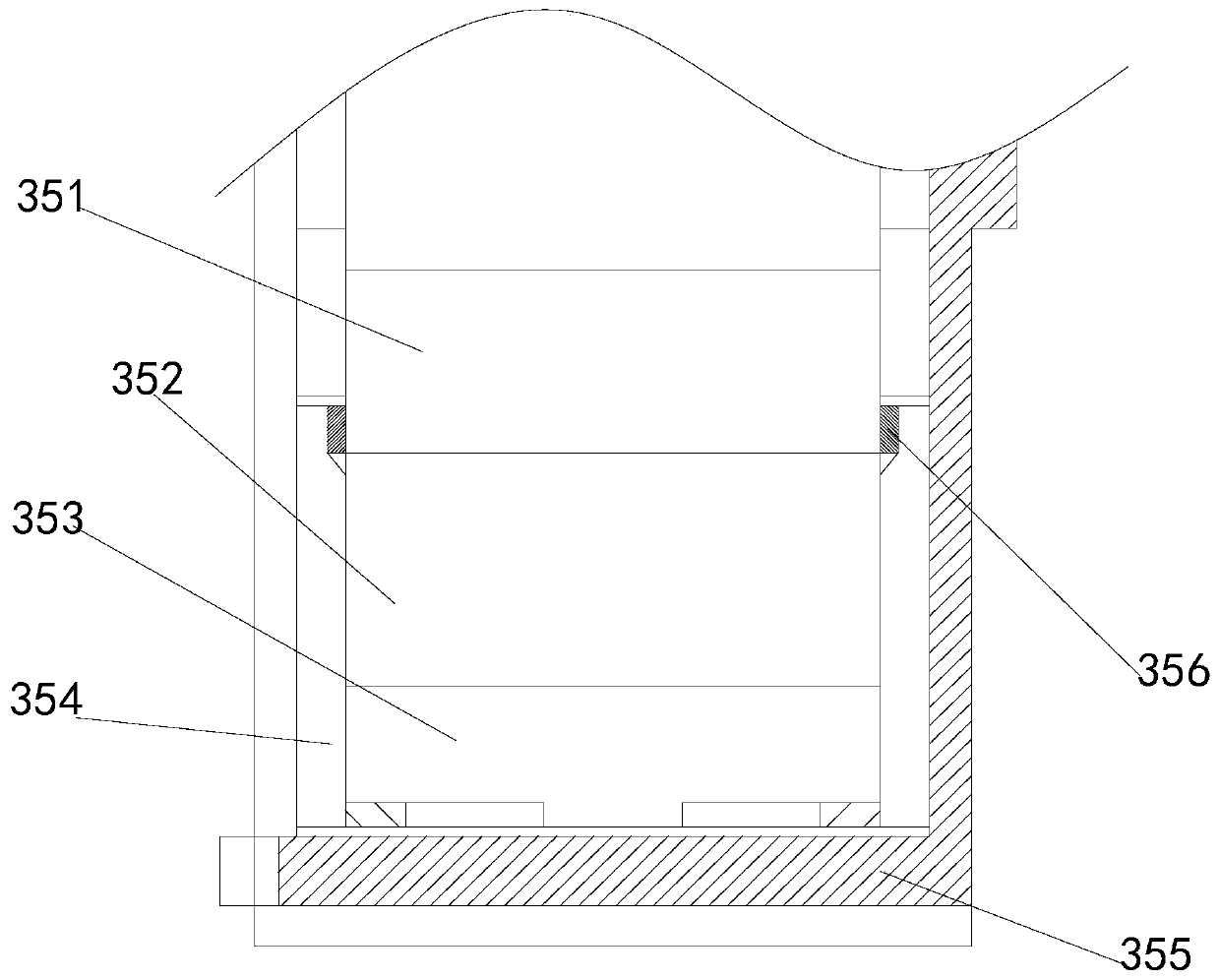

[0033] like Figure 6-Figure 8 Shown:

[0034] Wherein, the absorber 32 is provided with a pressure mechanism c1, a fixed rod c2, and an isolation rod c3, the pressure mechanism c1 and the fixed rod c2 are connected, the fixed rod c2 is welded on the inner wall of the isolation rod c3, and the isolation rod c3 Located on the same center line as the elastic rod 31, the pressure mechanism c1 is provided with a ring structure and a cylindrical structure, the fixed rod c2 runs through the center of the two structures, and the barrier acts on the inner cylinder structure of the pressure mechanism c1, so that the barrier It enters the injection pipe 2 through the pressure mechanism c1.

[0035] Wherein, the pressure mechanism c1 is provided with an engaging mechanism c11, an absorbing rod c12, a sealing plate c13, a rubber block c14, a compression block c15, and a compression column c16, and the sealing plate c13 and the engaging mechanism c11 is an integrated structure, the rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com