Small-flow and large-pressure-difference adjusting valve

A large pressure difference, regulating valve technology, applied in the field of high-parameter regulating valves, can solve the problems of the sealing pair losing the sealing performance, the valve core and the valve cage jamming, and the sealing pair not being tightly closed, so as to improve reliability and avoid sealing Influence of the effect, the effect of prolonging the service life

Inactive Publication Date: 2020-07-31

YICHUAN TECH CHENGDU CO LTD

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the structure of low entry and high exit, the impurities in the pipeline can easily enter the sealing part, but cannot be discharged smoothly from the flow hole of the cage, so it is very easy to cause the valve core and cage to get stuck, or be squeezed. In the middle of the sealing pair in the valve, the sealing pair is not closed tightly, resulting in leakage in the valve, causing the sealing pair to lose its sealing performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0038] Embodiment 2, based on the above embodiment 1, the size of each component of the valve of the present invention can be adjusted, so it is suitable for the small flow and large pressure difference regulating valve under different working conditions of most industrial production units.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

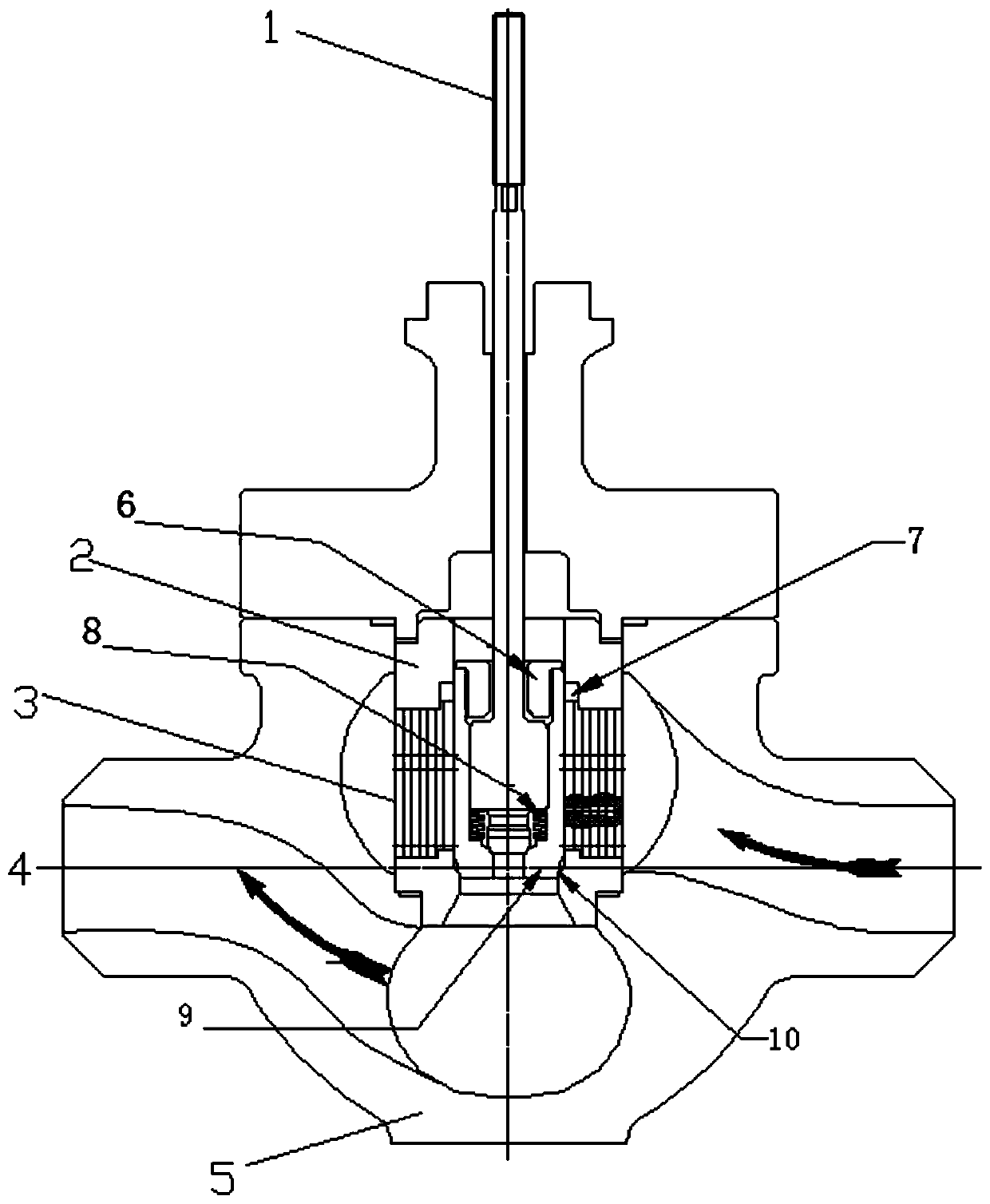

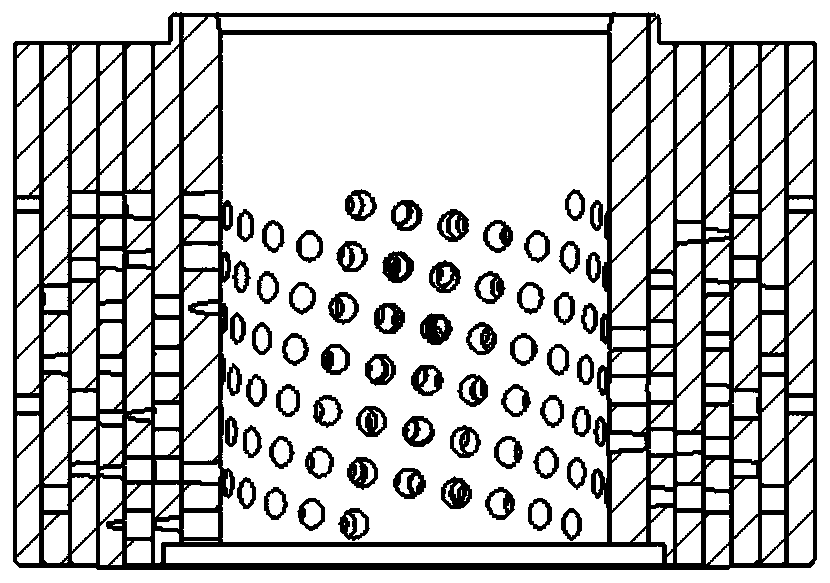

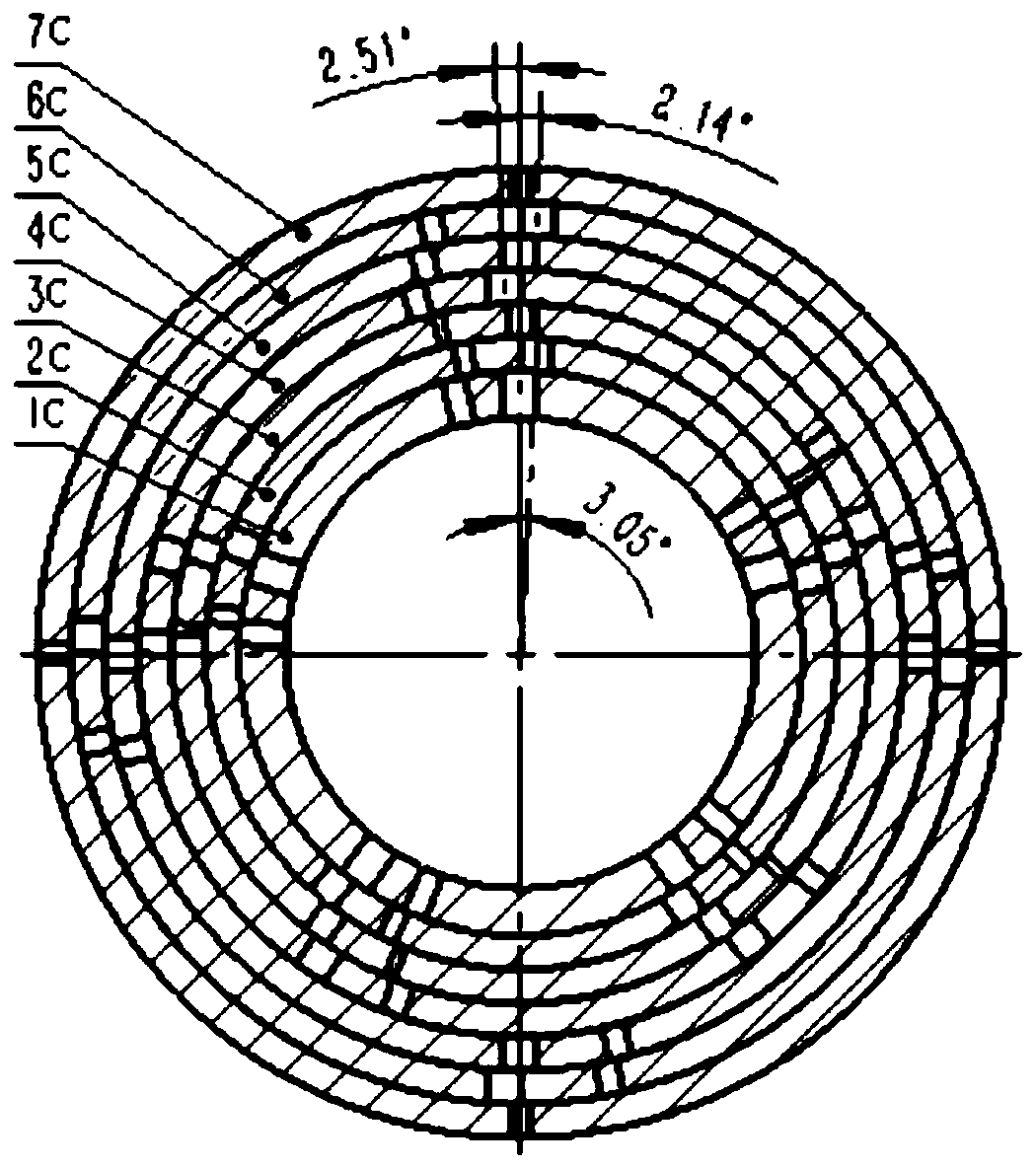

The invention discloses a small-flow and large-pressure-difference adjusting valve which comprises a valve element, a valve cover, a multi-layer shutoff reducing valve cage, a valve body, a valve headand a valve seat. The valve element and the valve rod are integrated, and the bottom of the valve element is mounted in the valve head. The multi-layer shutoff reducing valve cage is assembled in thevalve body, and the upper end of the valve seat is connected with an execution mechanism. A supporting ring is arranged above the multi-layer shutoff reducing valve cage, and a valve head seal is arranged in the multi-layer shutoff reducing valve cage. A valve head nut is arranged above the valve head. A butterfly spring is arranged below the valve head nut. According to the small-flow and large-pressure-difference adjusting valve, the influence of impurities in a pipeline on the sealing effect is effectively avoided, a sealing pair in the valve is protected better, the service life of the valve is prolonged, and the reliability of the valve is also improved.

Description

technical field [0001] The invention relates to the technical field of high-parameter regulating valves, in particular to a regulating valve with small flow rate and large pressure difference. Background technique [0002] Any industrial production has pipeline transmission and pipeline control equipment and facilities, but in the actual production and system operation process, under the condition of small flow, the pressure difference between the front and rear of the valve is the largest, the flow velocity of the medium in the valve is also the largest, and the temperature of the medium in the valve High, frequent opening and closing during operation, etc., it is extremely common that the working conditions cause severe erosion to the valve. The small flow and large pressure difference regulating valve is located at the outlet of the large high-pressure boiler feed water pump. Its main function is to open the valve to form a circulating backflow when the feed water pump is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16K47/08F16K3/24F16K3/314F16K27/04

CPCF16K3/246F16K3/314F16K27/041F16K47/08

Inventor 董玉泉阳运树

Owner YICHUAN TECH CHENGDU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com