Low-consumption vehicle air filter

An air filter, low-consumption technology, applied in fuel air filter, combustion air/combustion-air treatment, machine/engine, etc., can solve the problems of reduced filter performance, increased car maintenance costs, and affecting engine work, etc. , to achieve the effect of reducing replacement frequency, reducing maintenance costs and improving filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

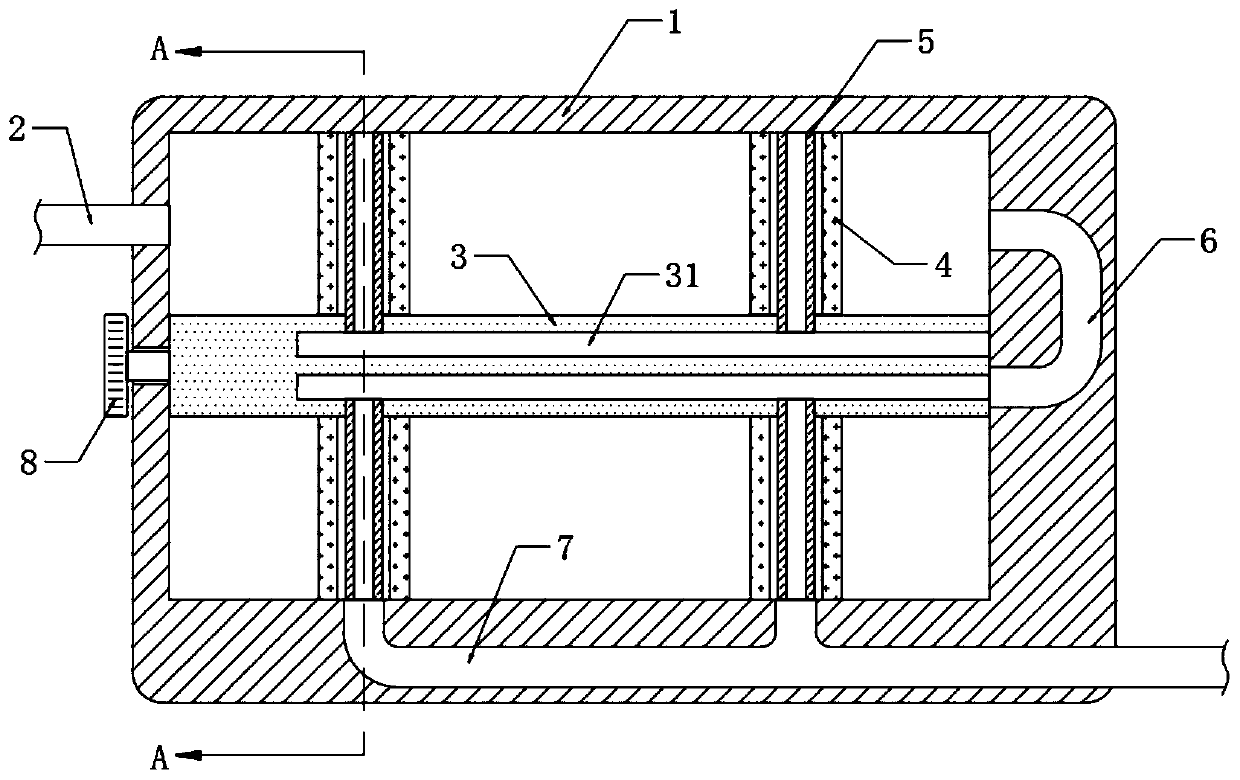

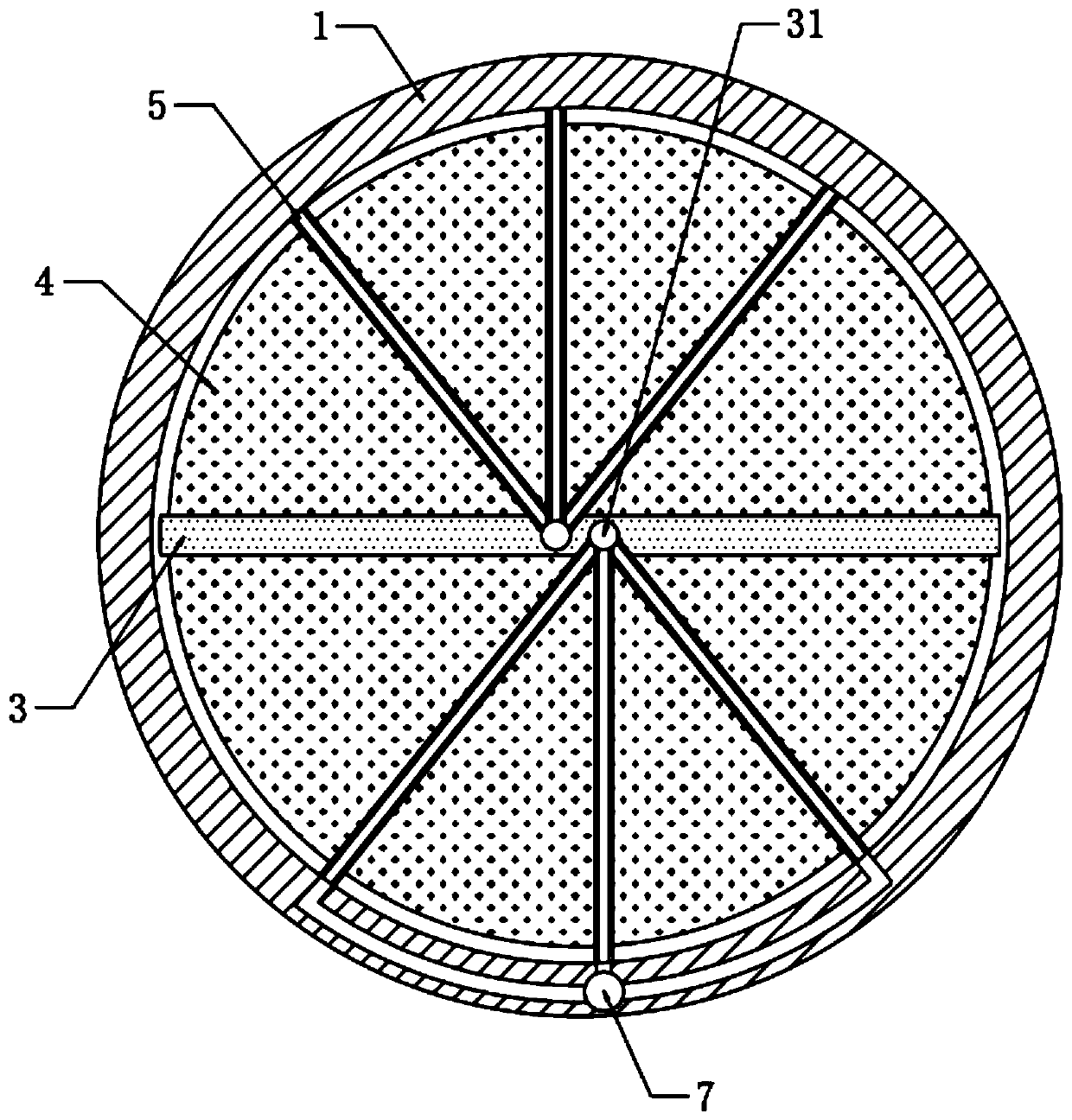

[0020] refer to Figure 1-2 , a low-consumption vehicle air filter, including a housing 1, the side wall of the housing 1 is installed with an air intake pipe 2 communicating with the inside, and the inner bottom of the housing 1 is also equipped with an air outlet pipe 7, the housing 1 A partition 3 is rotatably connected to the inner wall of the partition. It should be noted that the side wall of the partition 3 is against the inner wall of the housing 1 and divides the housing 1 into two chambers that are not connected to each other.

[0021] Both the upper end and the lower end of the partition plate 3 are equipped with a filter element 4, and the installation method of the filter element 4 is an existing mature technical means, which will not be described in detail here. Moreover, the filter element 4 is embedded with a plurality of elastic rubber pipes 5 . It should be noted that the outer walls of the rubber pipes 5 are fixedly connected with the filter element 4 . And...

Embodiment 2

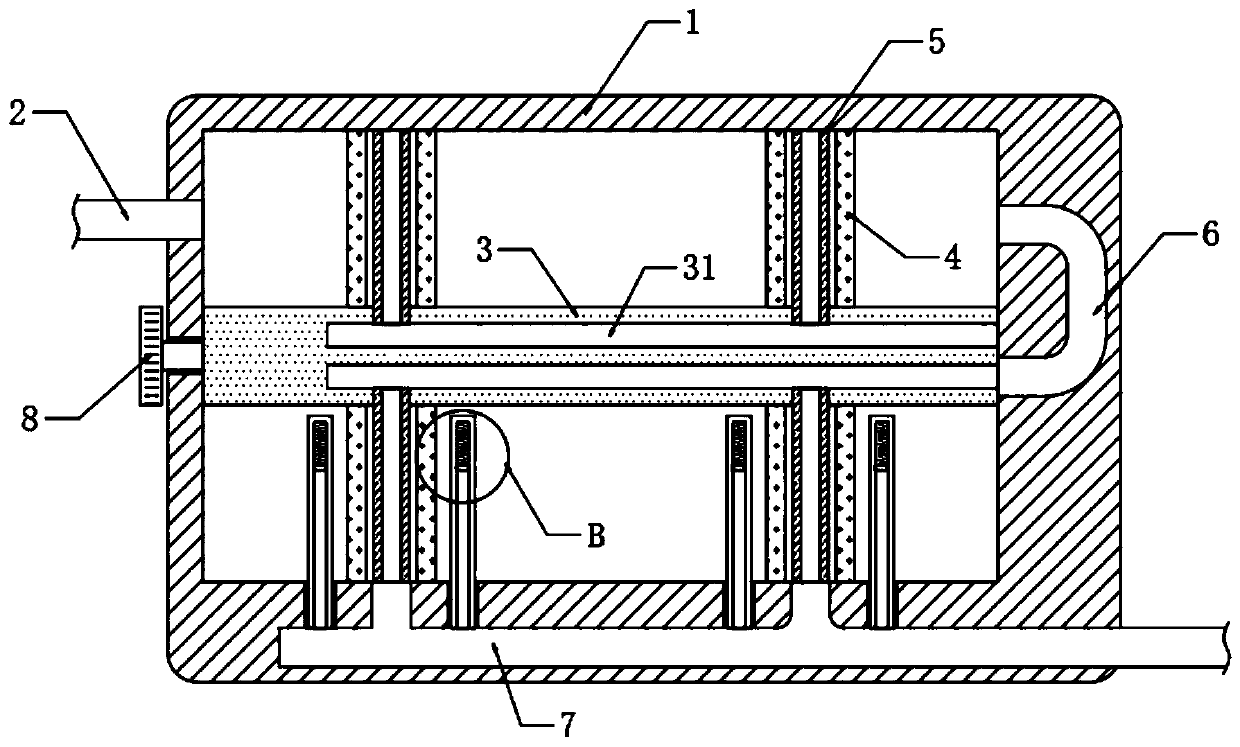

[0028] Referring to 3-4, the difference from the first embodiment is that the inner bottom of the housing 1 is embedded with a plurality of glass sleeves 9 communicating with the air outlet pipe 7, and every two adjacent glass sleeves are arranged symmetrically on the filter element 4 The two sides of the glass sleeve 9 are slidably connected with a slider 10 , and the side wall of the slider 10 is fixedly connected with a silk 101 .

[0029] It should be noted that the side wall of the slider 10 is in close contact with the inner wall of the glass sleeve 9 . (Specifically in the manufacturing process, the silk 101 is fixedly arranged on a part of the lower side of the slider 10, which can ensure that when the slider 10 moves up and down, the silk 101 can rub against the glass sleeve 9, and the slider 10 and the glass sleeve 9 There is also good airtightness between them).

[0030] The upper end of the slide block (10) is elastically connected to the inner top of the glass sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com