Segmented blasting hole excavation construction method for reconstruction and expansion of tunnel through karst landform water conservancy extra-small section

A segmented blasting and karst technology, applied in blasting, tunnels, mining equipment, etc., can solve problems such as complex geological conditions, affecting tunnel construction safety and later use functions, construction safety hazards, etc., to achieve simple and efficient construction machinery and equipment The effect of safe application range and simple construction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, not all of them.

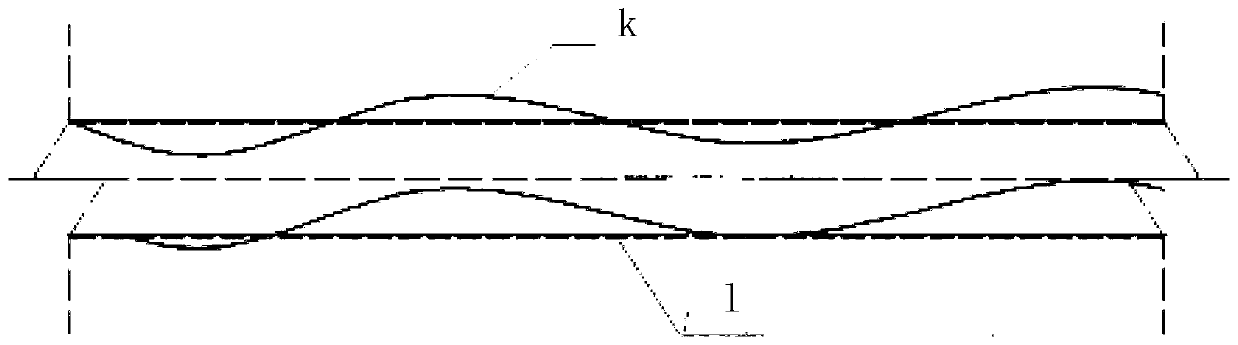

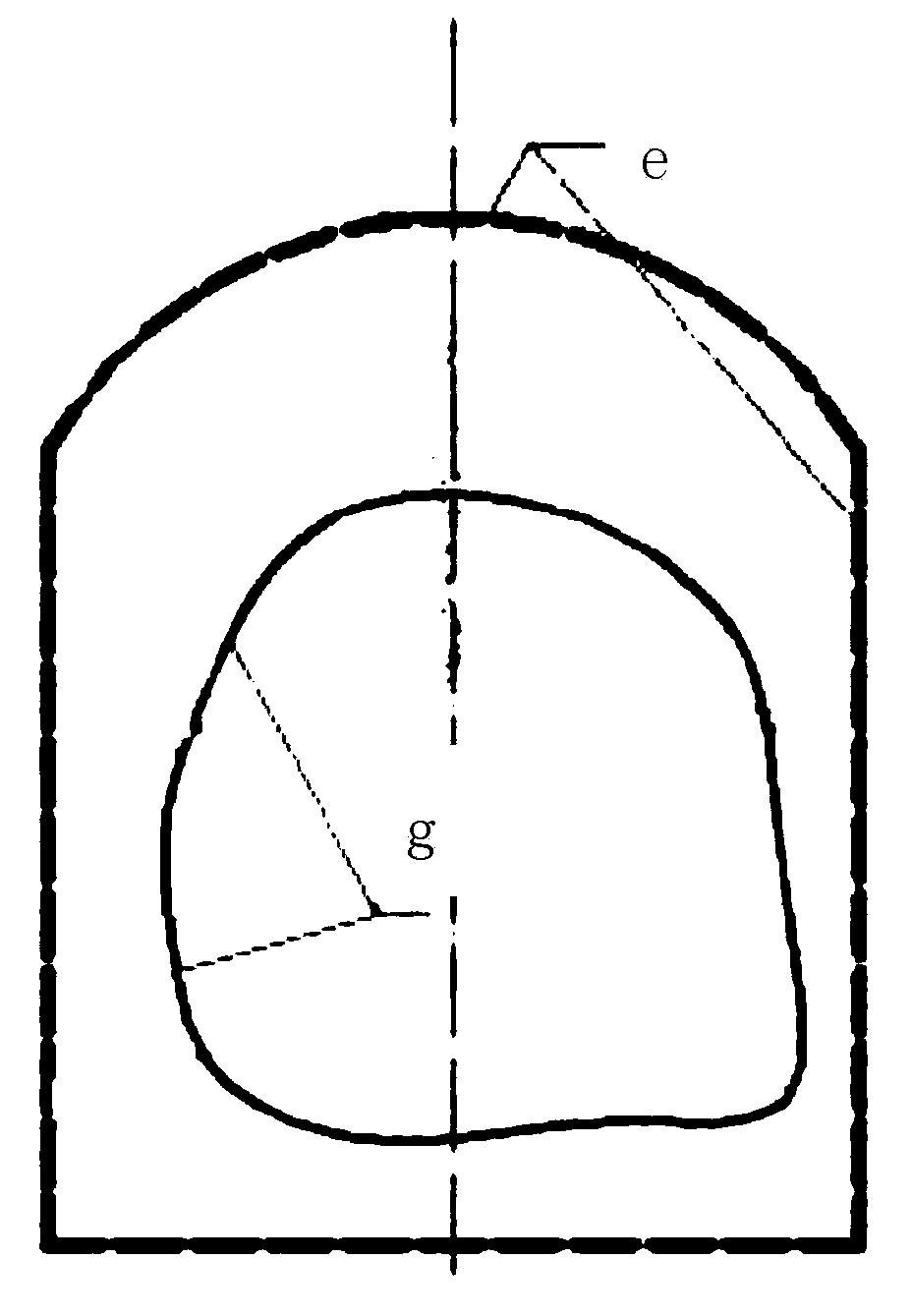

[0038] The segmental blasting excavation construction method for reconstruction and expansion of tunnels with ultra-small sections in karst landforms and water conservancy is used for reconstruction and expansion of original tunnels. The original tunnels are ultra-small sections, and the excavation section design of new tunnels adopts the city gate type; it includes the following steps:

[0039] S1. On-site survey and investigation of the surrounding rocks of the original tunnel, confirming that the surrounding rocks are classified as IV or V. The vertical fissures of many rock masses in the surrounding rocks are relatively developed, the karst is relatively developed, and the local rock masses are b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com