A method for internal cooling of mass concrete foundation

A large-volume concrete and internal cooling technology, applied in infrastructure engineering, construction, etc., can solve the problems of waste material cooling, long working cycle, unevenness, etc., and achieve the effects of saving labor costs, easy construction, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

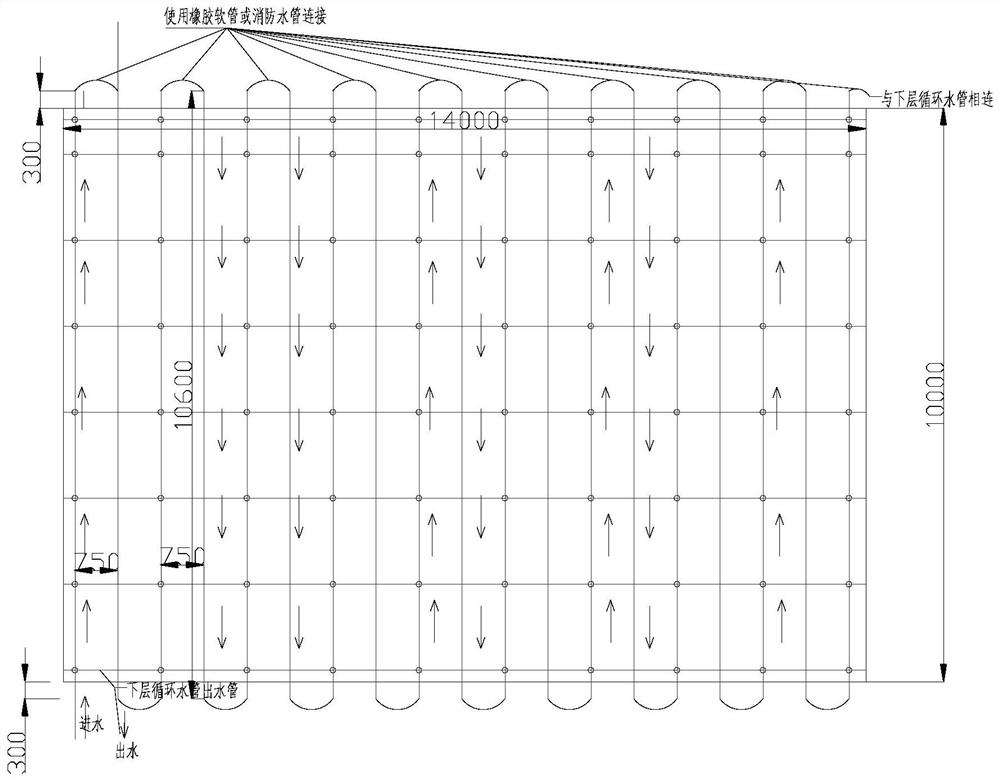

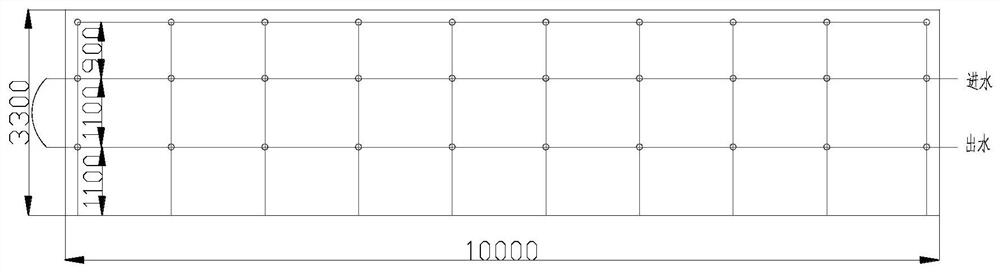

[0024] The construction object of this embodiment is: Qingdao Jinneng new material project compressor foundation SJ-12PK301 equipment undertaken by a certain unit, the foundation is a solid four-layer steel mesh sheet surrounded by hoops and closed steel cage concrete structure. The foundation is 14m long, 10m wide and 3m thick, and belongs to the mass concrete structure. The top layer of steel mesh and the bottom layer of steel mesh are both double-layer two-way steel mesh with a diameter of 28mm and a spacing of 150mm. The middle layer of steel mesh is arranged with two layers of steel mesh with a diameter of 16mm and a spacing of 300mm. Due to the large diameter of the steel bar and the large number of layers, a steel pipe support frame with two layers of steel mesh sheets on the top layer and the middle layer is installed inside. The support frame is designed with a vertical and horizontal spacing of 1.5m*1.5m. Three layers of horizontal rod support are set on the three la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com