Device for detecting bearing capacity of pile soil composite foundation

A technology of composite foundation and bearing capacity, which is used in foundation structure engineering, on-site foundation soil survey, construction, etc., can solve the problems of load-bearing plate tilt, load-bearing plate dumping, accelerated jack damage, etc., to avoid direct dumping and long recovery time. , the effect of prolonging the pouring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

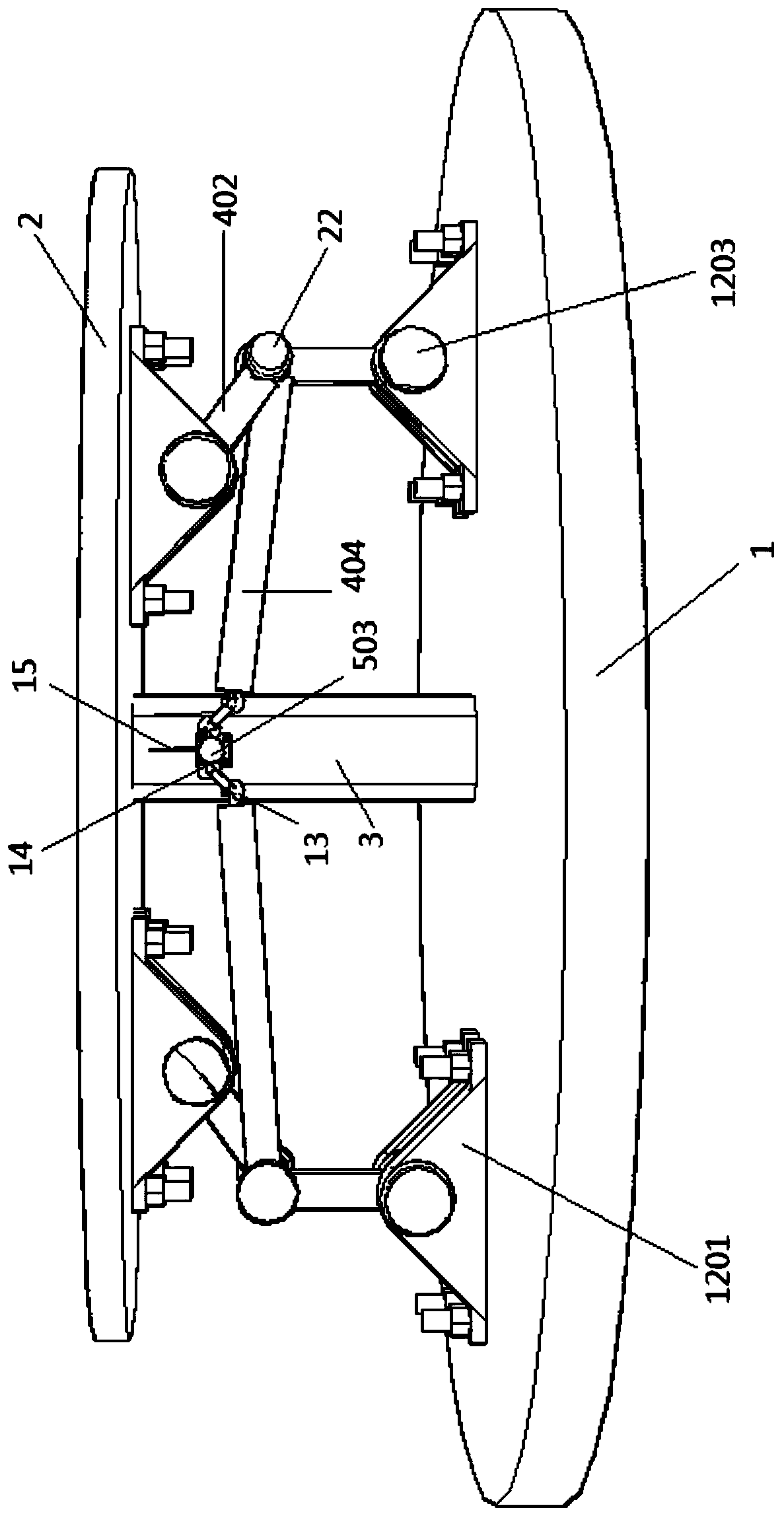

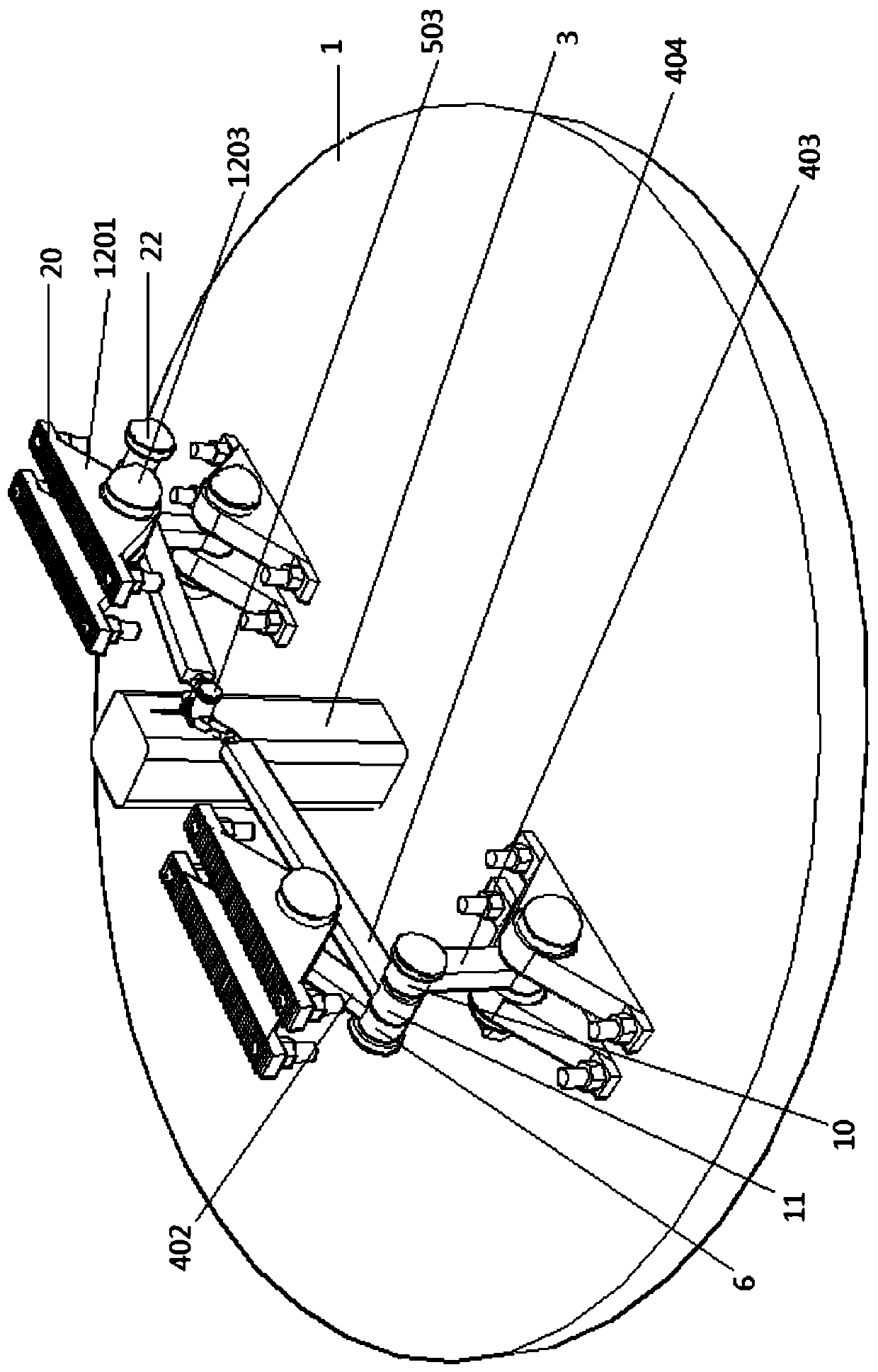

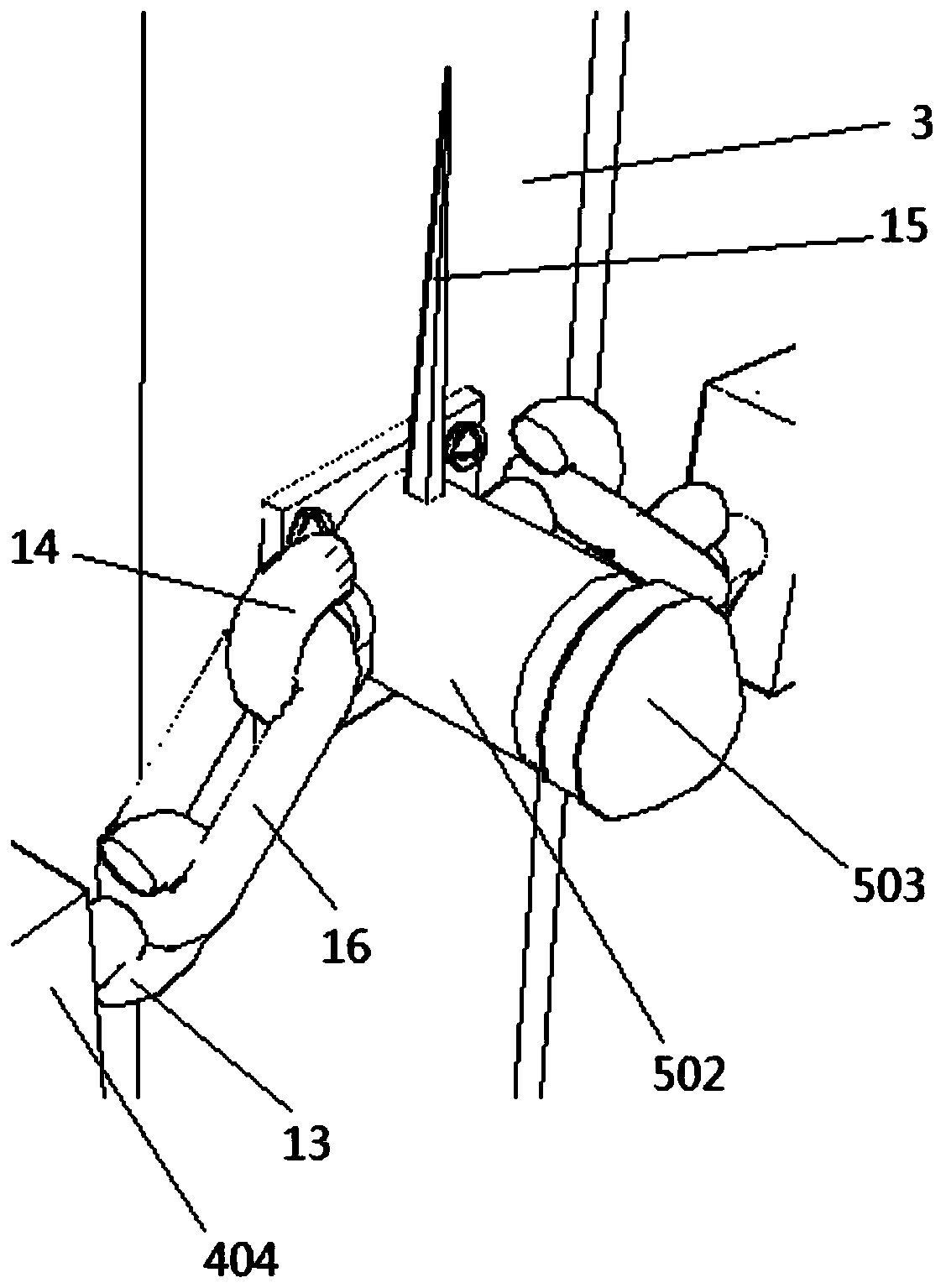

[0030] refer to Figure 1-4 , Figure 6 and Figure 7, this embodiment 1 introduces a device for testing the bearing capacity of pile-soil composite foundations, the device column includes a load-bearing plate 1, a load-bearing plate 2 2, a support pile 3, a balance adjustment mechanism 4 and an inclination indicating mechanism 5; The bottom end of support pile 3 is fixedly connected with load-bearing plate one 1, the top of support pile 3 is movably connected with load-bearing plate two 2, and the centerlines of support pile 3, load-bearing plate one 1 and load-bearing plate two 2 coincide; support pile 3, load-bearing plate one 1 and the load-bearing plate 2 form a rigid and movable support device, the top of the support pile 3 is connected with the load-bearing plate 2 movably, and the load-bearing plate 2 can tilt left and right with the 3 fulcrums of the support pile when the force is uneven There are two balance adjustment mechanisms 4, two balance adjustment mechanism...

Embodiment 2

[0032] refer to Figure 1-4 , Figure 6 and Figure 7 , on the basis of the first embodiment, this embodiment further defines the rotation angle of the balance adjustment arm one 402, and by limiting the rotation angle, the stable state of the balance adjustment mechanism 4 during operation is ensured.

[0033] This embodiment 1 introduces a device for testing the bearing capacity of pile-soil composite foundations. The device column includes a load-bearing plate 1, a load-bearing plate 2, a supporting pile 3, a balance adjustment mechanism 4, and an inclination indicating mechanism 5; The bottom of the pile 3 is fixedly connected with the load-bearing plate 1, and the top of the support pile 3 is movably connected with the load-bearing plate 2 2, and the centerlines of the support pile 3, the load-bearing plate 1 and the load-bearing plate 2 coincide; And a support device with both rigidity and mobility is formed between the load-bearing plates 2 and 2. The top of the suppo...

Embodiment 3

[0035] refer to Figure 1-7 , on the basis of Embodiment 2: This embodiment elaborates the connection mode between bearing 1, bearing 2 and bearing 3 and the movable shaft, which is beneficial to the connection between bearing 1, bearing 2 and bearing 3 and the movable shaft 401 Fixed connection.

[0036] Wherein, the movable shaft 401 is provided with a first bearing groove 17, a second bearing groove 18 and a third bearing groove 19, the first bearing is engaged in the first bearing groove 17, the second bearing is engaged in the second bearing groove 18, The three bearings are engaged in the three bearing grooves 19 inside. Bearing 1 is engaged in bearing 1 groove 17, bearing 2 is engaged in bearing 2 groove 18 and bearing 3 is engaged in bearing 3 groove 19, so that bearing 1, bearing 2 and bearing 3 can be guaranteed The firmness of the connection on the 401.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com