Silver-loaded nano cellulose, preparation method thereof and antibacterial composite material

A technology of nanocellulose and composite materials, applied in the field of silver-loaded nanocellulose and its preparation, and antibacterial composite materials, can solve the problems of high surface energy, easy agglomeration and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

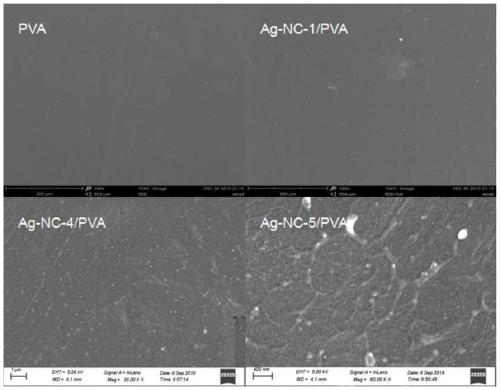

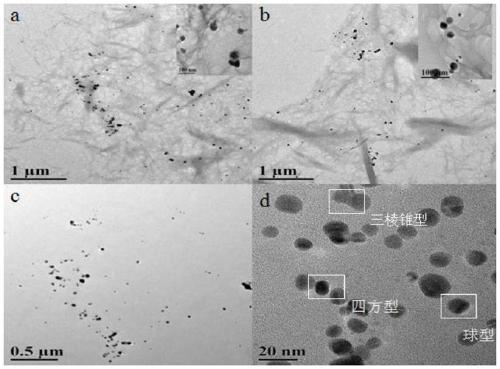

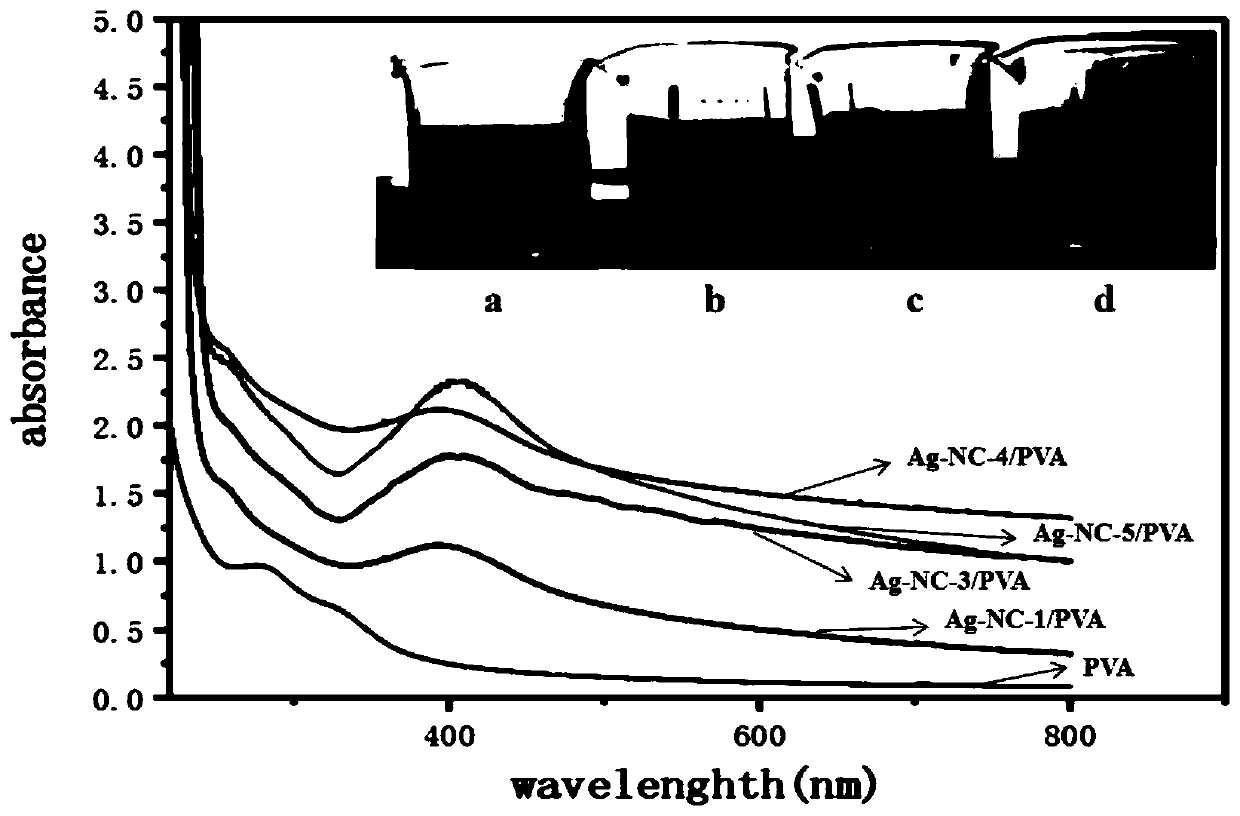

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of silver-loaded nano cellulose, comprising the following steps:

[0030] lignonanocellulose, tetramethylpiperidine oxide, NaBr and Na 2 CO 3 -NaHCO 3 The buffer solution is mixed to obtain a lignonanocellulose suspension;

[0031] The lignonanocellulose suspension is mixed with NaClO aqueous solution and then oxidized to obtain carboxylated lignonanocellulose;

[0032] The carboxylated lignonanocellulose, AgNO 3 , NaBH 4 It is mixed with water, and the reduction reaction is carried out under the condition of avoiding light, so as to obtain the silver-loaded nano-cellulose.

[0033] In the present invention, lignonanocellulose, tetramethylpiperidine oxide, NaBr and Na 2 CO 3 -NaHCO 3 The buffer solution is mixed to obtain a lignonanocellulose suspension. The present invention has no special limitation on the source of the lignonanocellulose, which can be prepared by commercially available products or well-know...

Embodiment 1

[0052] (1) preparing silver-loaded nanocellulose, comprising the following steps:

[0053] Na 2 CO 3 and NaHCO 3 Dissolve in water to give Na 2 CO 3 -NaHCO 3 buffer solution, wherein, the Na 2 CO 3 and NaHCO 3 The mass ratio is 7:3, Na 2 CO 3 and NaHCO 3 The total concentration of 0.1mol / L;

[0054] Weigh 0.5g of tetramethylpiperidine oxide and 1g of NaBr, dissolve the two in 250mL of the buffer solution, and then add 2.5g of lignonanocellulose to obtain a lignonanocellulose suspension;

[0055] Under stirring conditions, the pH value of 4 mL of NaClO aqueous solution (concentration: 0.4 mmol / g) was adjusted to 10 with hydrochloric acid (concentration: 28 wt%), and then the resulting solution was added dropwise to the wood at a rate of 2 drops / second. In the nanocellulose suspension, react at 25°C for 4 hours under stirring conditions; then add 2.5mL ethanol to the obtained system to terminate the reaction, filter, wash the filter cake with deionized water until ne...

Embodiment 2

[0061] Prepare Ag-NC / PVA composite film according to the method of embodiment 1, the difference is that, AgNO 3 The addition amount of is 0.051g, then the volume fraction of silver nanoparticles in the silver-loaded nanocellulose dispersion obtained after the reduction reaction is 3%, and the final gained Ag-NC / PVA composite film is recorded as Ag-NC-3 / PVA film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com