Novel fiber-reinforced alkali-activated slag concrete material and preparation method thereof

A fiber-reinforced, alkali-activated technology, applied in the field of concrete building materials, can solve the problems of low splitting tensile strength and flexural strength, reduce concrete strength, etc., and achieve the effect of solving the shortage of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A fiber-reinforced alkali-excited slag concrete material and a preparation method thereof, comprising the following steps:

[0018] (1) Weigh the required materials accurately, 414 parts of slag, 29 parts of sodium hydroxide, 138 parts of water glass, 515 parts of sand, 717 parts of crushed stone, 239 parts of coal gangue, 166 parts of water, and 8 superplasticizers. parts, 13.3 parts of basalt fiber.

[0019] (2) Use all water to prepare sodium hydroxide solution first, and after standing for a period of time, pour water glass into it to prepare an alkali excitation solution.

[0020] (3) Mix the slag, sand, gravel, coal gangue and superplasticizer evenly, and gradually add basalt fiber during this process to prevent fiber agglomeration.

[0021] (4) Pour the prepared alkali excitation solution into the mixed material gradually, and stir in time while pouring into the solution, so that the slag is fully excited. Mix again and evenly.

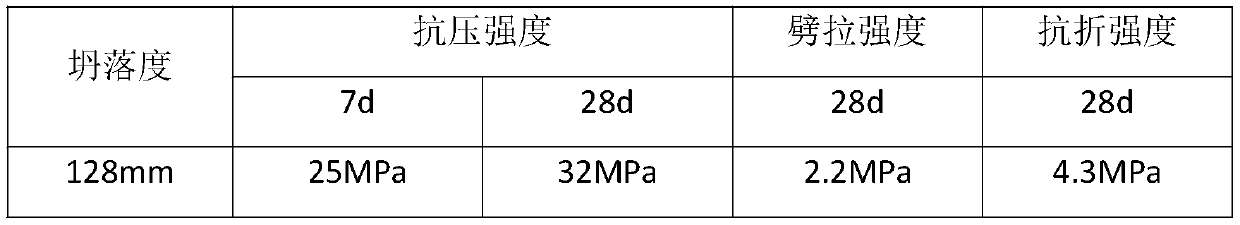

[0022] A fiber-reinforced alka...

Embodiment 2

[0029] A fiber-reinforced alkali-excited slag concrete material and a preparation method thereof, comprising the following steps:

[0030] (1) Weigh the required materials accurately, 414 parts of slag, 29 parts of sodium hydroxide, 138 parts of water glass, 515 parts of sand, 717 parts of crushed stone, 239 parts of coal gangue, 166 parts of water, and 8 superplasticizers. parts, 13.3 parts of basalt fiber.

[0031] (2) Prepare a sodium hydroxide solution with a part of water, and after standing for a period of time, pour water glass into it to prepare an alkali excitation solution.

[0032] (3) Mix slag, sand, crushed stone, coal gangue, superplasticizer and basalt fiber together.

[0033] (4) Pour the prepared alkali excitation solution into the mixed material gradually, and stir in time while pouring into the solution, so that the slag is fully excited. Mix again and evenly.

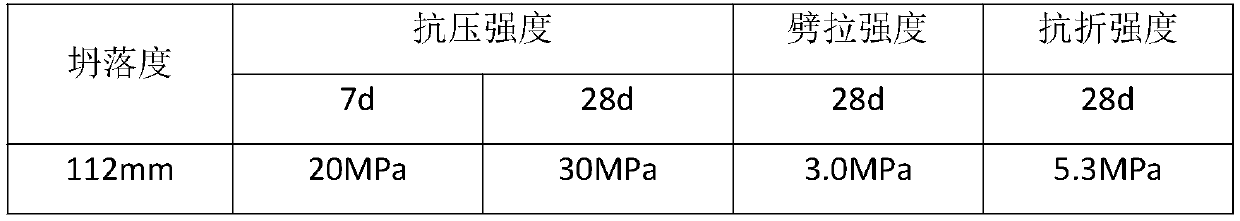

[0034] A fiber-reinforced alkali-excited slag concrete material according to claim, characteri...

Embodiment 3

[0041] The present embodiment provides a novel fiber-reinforced alkali-excited slag concrete material and a preparation method thereof. The main points of the preparation process are as follows:

[0042] A fiber-reinforced alkali-excited slag concrete material and a preparation method thereof, comprising the following steps:

[0043] (1) Weigh the required materials accurately, 414 parts of slag, 29 parts of sodium hydroxide, 138 parts of water glass, 515 parts of sand, 717 parts of crushed stone, 239 parts of coal gangue, 166 parts of water, and 8 superplasticizers. parts, 13.3 parts of basalt fiber.

[0044] (2) Prepare a sodium hydroxide solution with a part of water, and after standing for a period of time, pour water glass into it to prepare an alkali excitation solution.

[0045] (3) Mix the slag, sand, gravel, coal gangue and superplasticizer evenly, and gradually add basalt fiber during this process to prevent fiber agglomeration.

[0046] The prepared alkali excitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com