Lubricating oil biological base oil and preparation method thereof

A technology of base oil and lubricating oil, which is applied in the field of lubricating oil, can solve the problems of poor biodegradability, ecological environment pollution, lubricating oil stability and insufficient biodegradability, etc., to achieve low environmental pollution, meet environmental protection requirements, The effect of abundant raw material reagent resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

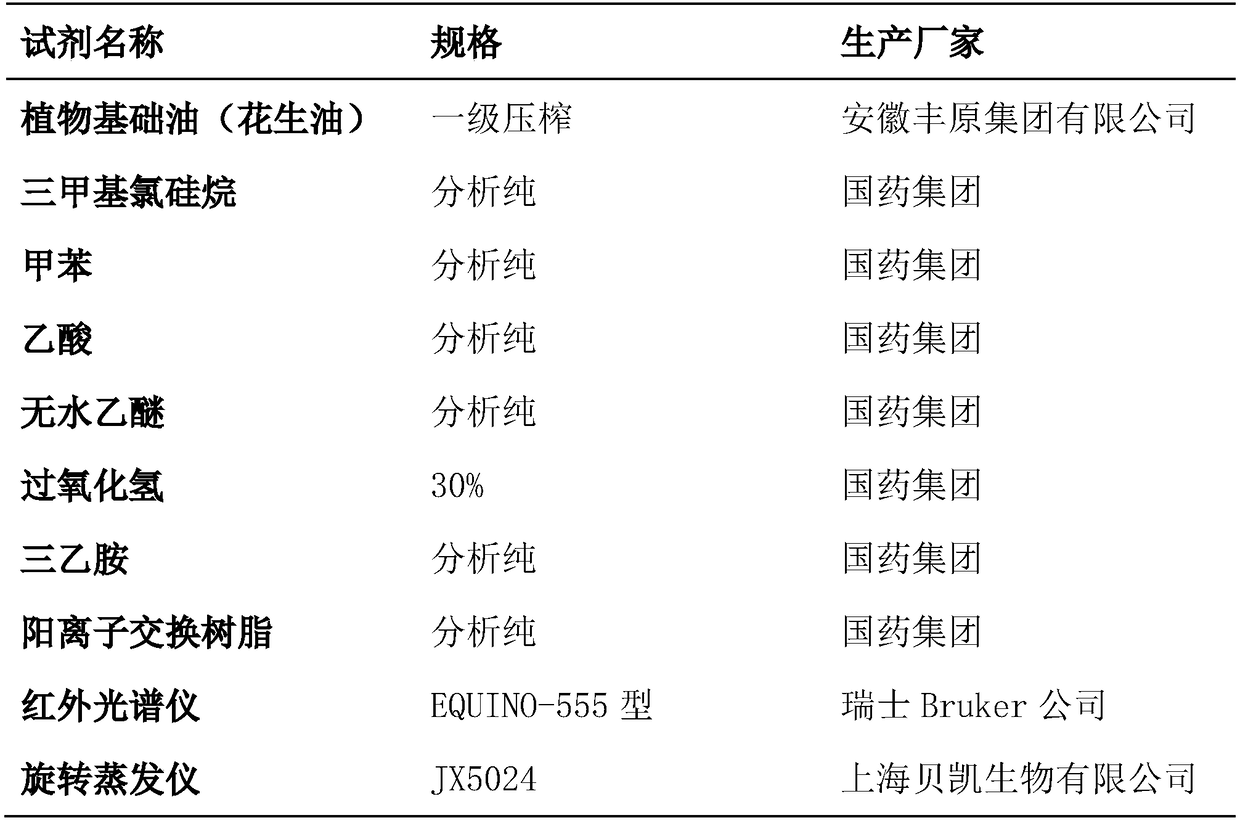

[0021] A biological base oil for lubricating oil, the biological base oil for lubricating oil has the following components: 30 parts of vegetable base oil, 1.5 parts of trimethylchlorosilane, 15 parts of toluene, 3.2 parts of acetic acid, 4 parts of anhydrous ether, hydrogen peroxide 3.9 parts, 1.5 parts of triethylamine and 3 parts of catalyst.

[0022] A preparation method of lubricating oil biological base oil, the preparation method of described lubricating oil biological base oil is as follows:

[0023] S1: Weigh the dehydrated vegetable base oil, put it in a vacuum mixing tank, add toluene as a solvent in the mixing tank, turn on the mixing tank to stir, and then slowly add trimethylchlorosilane into the mixing tank during the stirring process Stir for 15 minutes, keep the temperature of the mixing tank at 55°C and keep it warm for 4 hours;

[0024] S2: Add catalyst and acetic acid to the product obtained in S1, control the temperature at 50°C, stir for 15 minutes, then...

Embodiment 2

[0033] A kind of lubricating oil biological base oil, this lubricating oil biological base oil, its composition is as follows: 45 parts of vegetable base oils, 1.8 parts of trimethylchlorosilane, 20 parts of toluene, 3.8 parts of acetic acid, 5 parts of anhydrous ethers, hydrogen peroxide 4.3 parts, 1.8 parts of triethylamine and 4 parts of catalyst.

[0034] A preparation method of lubricating oil biological base oil, the preparation method of described lubricating oil biological base oil is as follows:

[0035] S1: Weigh the dehydrated vegetable base oil, put it in a vacuum mixing tank, add toluene as a solvent in the mixing tank, turn on the mixing tank to stir, and then slowly add trimethylchlorosilane into the mixing tank during the stirring process Stir for 15 minutes, keep the temperature of the mixing tank at 55°C and keep it warm for 4 hours;

[0036] S2: Add catalyst and acetic acid to the product obtained in S1, control the temperature at 50°C, stir for 15 minutes,...

Embodiment 3

[0045] A biological base oil for lubricating oil, the biological base oil for lubricating oil has the following components: 55 parts of vegetable base oil, 2.2 parts of trimethylchlorosilane, 25 parts of toluene, 3.8 parts of acetic acid, 6 parts of anhydrous ether, hydrogen peroxide 4.5 parts, 2 parts of triethylamine and 5 parts of catalyst.

[0046] A preparation method of lubricating oil biological base oil, the preparation method of described lubricating oil biological base oil is as follows:

[0047] S1: Weigh the dehydrated vegetable base oil, put it in a vacuum mixing tank, add toluene as a solvent in the mixing tank, turn on the mixing tank to stir, and then slowly add trimethylchlorosilane into the mixing tank during the stirring process Stir for 15 minutes, keep the temperature of the mixing tank at 55°C and keep it warm for 4 hours;

[0048] S2: Add catalyst and acetic acid to the product obtained in S1, control the temperature at 50°C, stir for 15 minutes, then s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com