A kind of bottom unloading type supercritical extraction kettle and using method

A supercritical and extraction kettle technology, applied in the field of bottom discharge type supercritical extraction kettle, can solve the problems such as the effect of upper discharge slag on the efficiency, the secondary loosening of the raw material structure, and the reduction of extraction efficiency, saving manpower and material resources and venting time. The effect of shortening and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

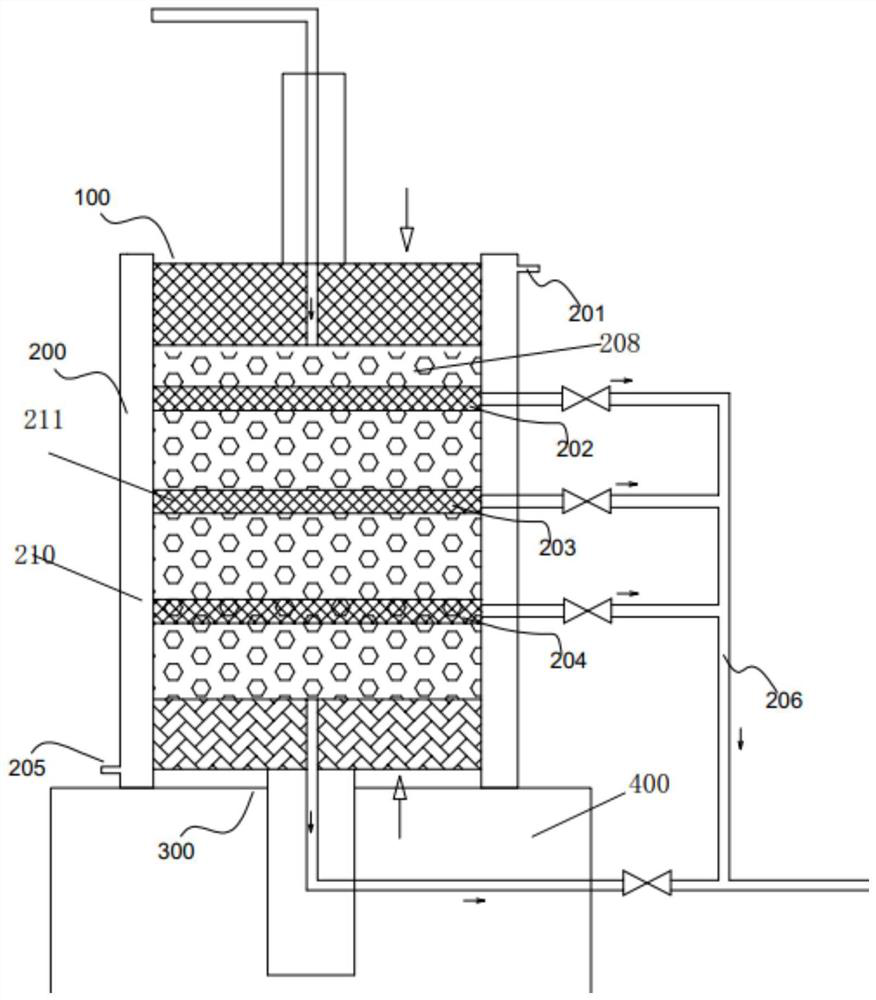

[0054] Such as Figure 1 to Figure 3 As mentioned above, a bottom discharge supercritical extraction kettle of the present invention comprises an upper extruding device 100, a kettle body 200, and a lower extruding device 300;

[0055] The upper and lower ends of the kettle body 200 are open, and the inner wall is smooth. The upper end of the kettle body 200 is sealed and connected to the upper extrusion device 100, and the lower end is sealed and connected to the lower extrusion device 300. A temperature control layer 210 is arranged outside the kettle body 200. A kettle cavity 208 is formed inside the kettle body 200;

[0056] The upper extrusion device 100 includes an upper thrust round table 103, an upper push rod 101, an upper filter plate 104, and an upper air circuit 102; the lower extrusion device 300 includes a lower thrust round table 302, a lower push rod 304, and a lower filter plate 301 and the lower air passage 303; the upper extruding device 100 and the lower e...

Embodiment 2

[0060] Such as Figure 1 to Figure 3 As mentioned above, a bottom discharge supercritical extraction kettle of the present invention comprises an upper extruding device 100, a kettle body 200 and a lower extruding device 300;

[0061] The upper and lower ends of the kettle body 200 are open, and the inner wall is smooth. The upper end of the kettle body 200 is sealed and connected to the upper extrusion device 100, and the lower end is sealed and connected to the lower extrusion device 300. A temperature control layer 210 is arranged outside the kettle body 200. A kettle cavity 208 is formed inside the kettle body 200;

[0062] The upper extrusion device 100 includes an upper thrust round table 103, an upper push rod 101, an upper filter plate 104, and an upper air circuit 102; the lower extrusion device 300 includes a lower thrust round table 302, a lower push rod 304, and a lower filter plate 301 and the lower air passage 303; the upper extruding device 100 and the lower ex...

Embodiment 3

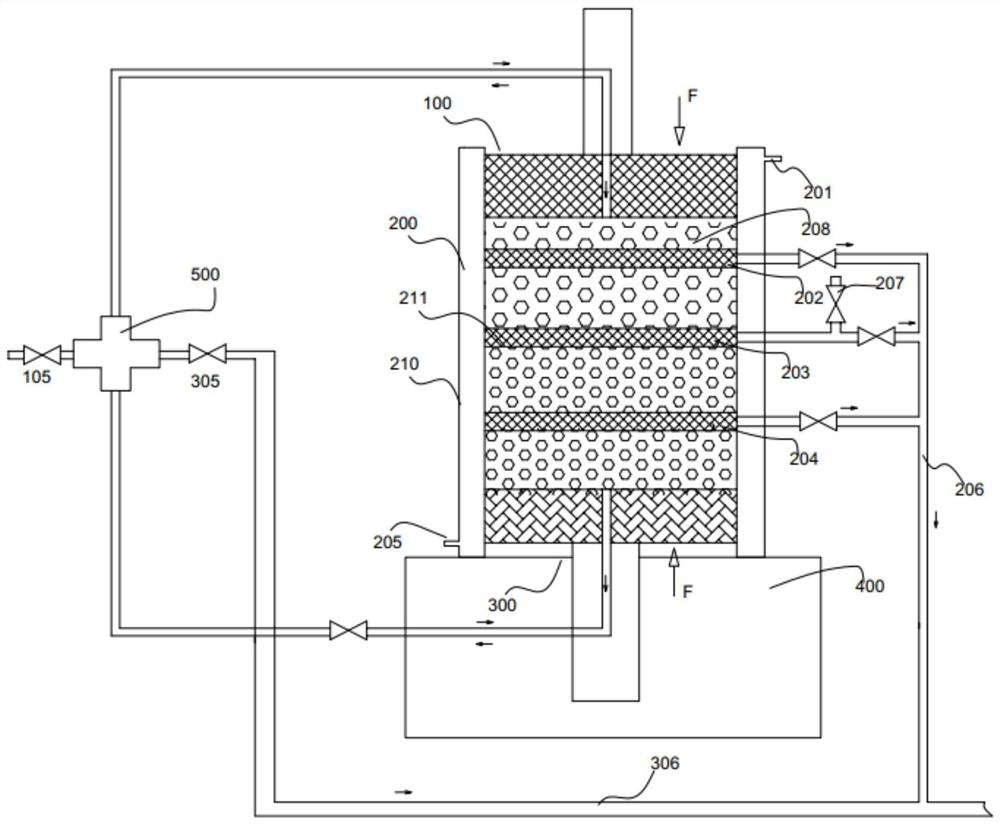

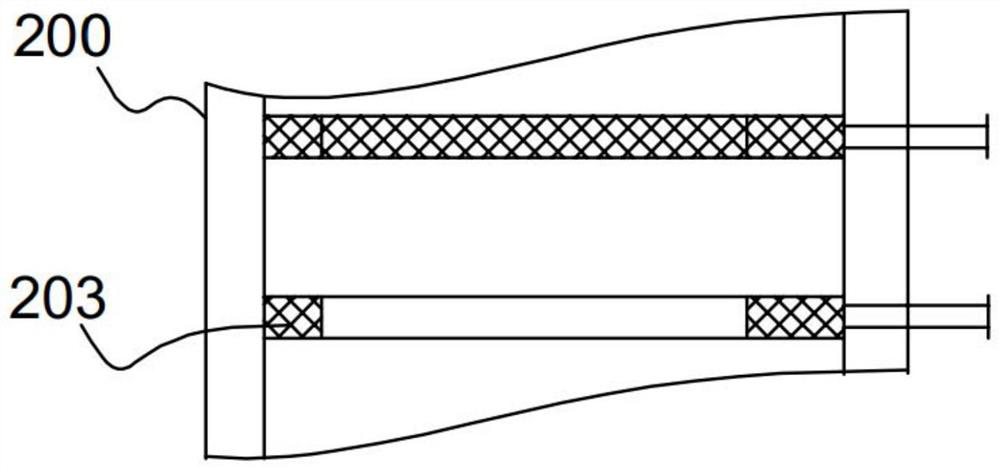

[0066] On the basis of Example 1, such as figure 2 and image 3 As shown, the inner wall of the still body 200 is also provided with some annular grooves (or arc-shaped grooves) and some side outlet pipelines; one side of the groove is provided with a filter belt 211, and the other side of the groove is connected to the side outlet pipeline ( 202, 203, 204) are connected, and all the side outlet pipelines are converged to the side main outlet pipeline 206 and then connected to the main outlet pipeline 306.

[0067] This embodiment is an upper air inlet and lower air outlet, with an annular groove structure. The working method of this embodiment is: open the outlet valve 305 of the extraction kettle, open the temperature control layer 210, move the upper extrusion device 100 to the outside of the kettle, and The extruding device 300 moves down to the lowest point in the kettle. To start charging, it is required that the materials to be extracted (such as soybeans, rapeseed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com