Device and method for measuring permeability of steel slag concrete

A technology of steel slag concrete and measuring device, which is used in measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of complicated operation and large measurement error, and achieves simplified operation process and small error of measurement result. , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

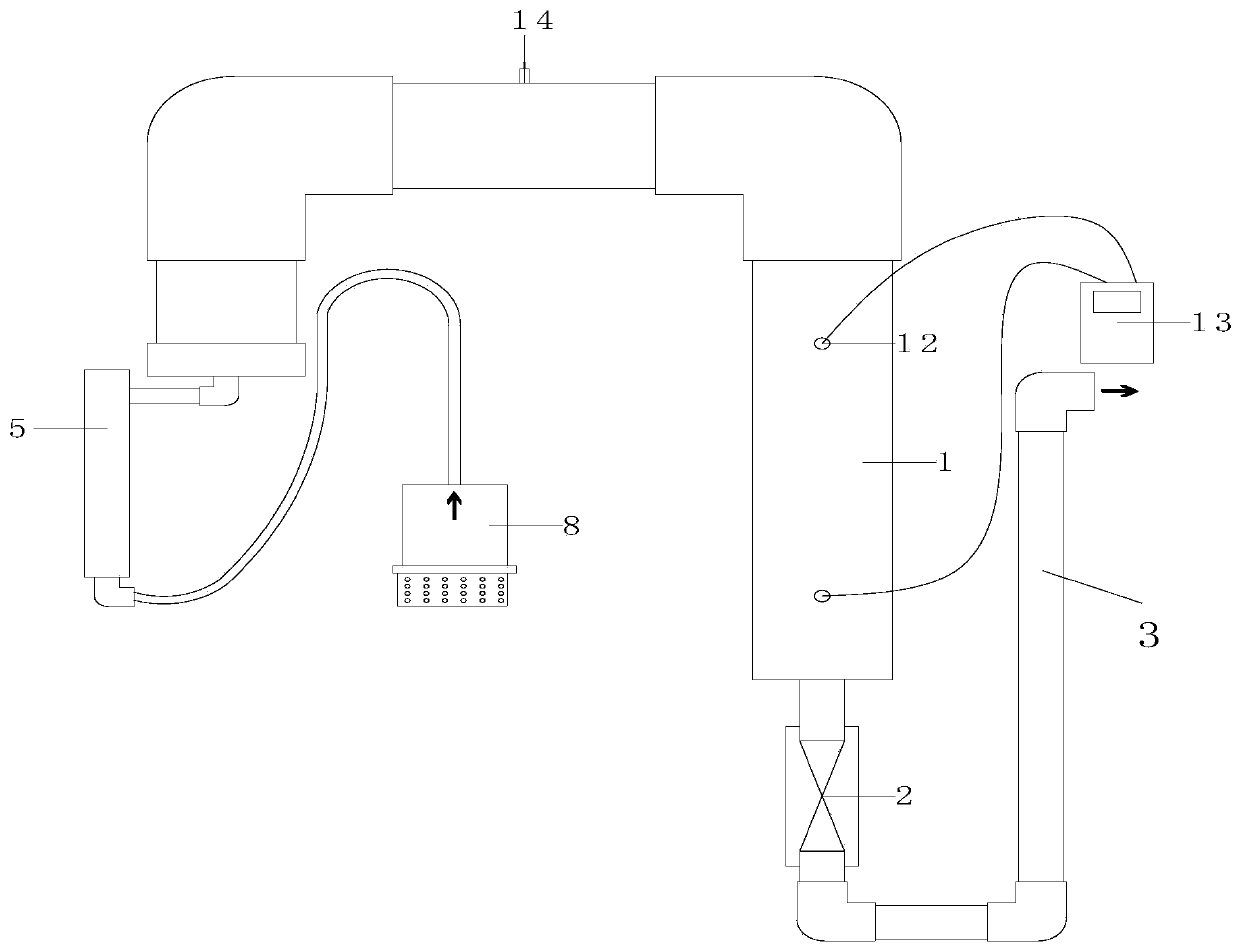

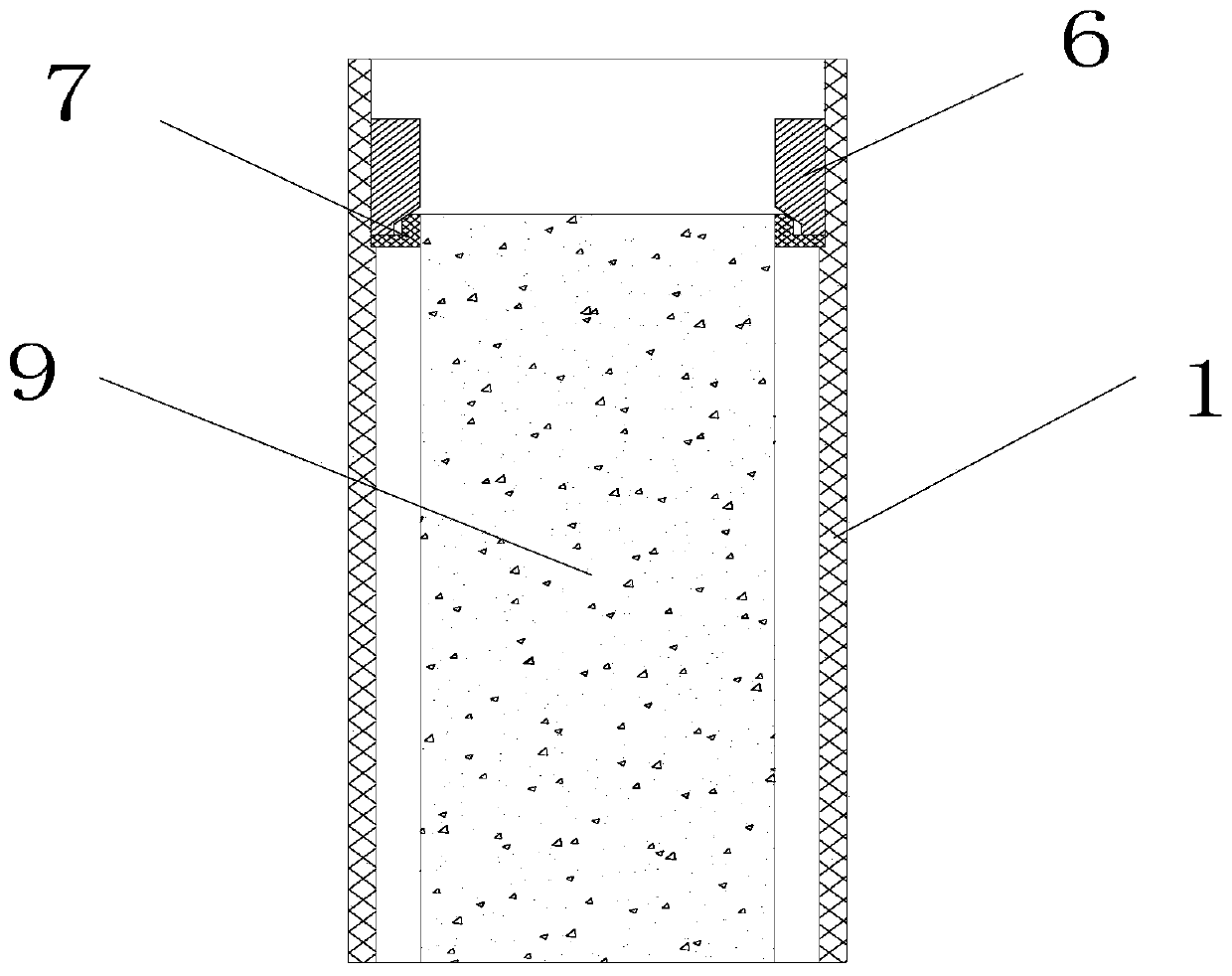

[0022] Such as Figure 1 to Figure 4 As shown, a steel slag concrete permeability measuring device includes a first PVC pipe 1 and a second PVC pipe, and the first PVC pipe 1 is connected with a ball valve 2 and a third PVC pipe 3 in turn through a connector, and the second PVC pipe The two ends of the two ends are respectively connected to the flow meter 5 and the third PVC pipe 3 through the connector, the flow meter 5 is connected to the water pump 8, the water pump 8 is connected to the water tank, and the test piece 9 is placed in the third PVC pipe 3, and the second PVC pipe The top is provided with an air release valve 14, and a pressure sensor 12 is installed at both ends of the third PVC pipe 3 test piece 9, and the pressure sensor 12 is connected with a digital differential pressure gauge 13 signal; the upper part of the third PVC pipe 3 is provided with a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com