A Colloid Thruster Based on Microwave Enhancement

A thruster and microwave technology, applied in thrust reversers, using plasma, machines/engines, etc., can solve the problems of reducing the proportion of ions and reducing the specific impulse, and achieve the effect of reducing the field emission voltage and high specific impulse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

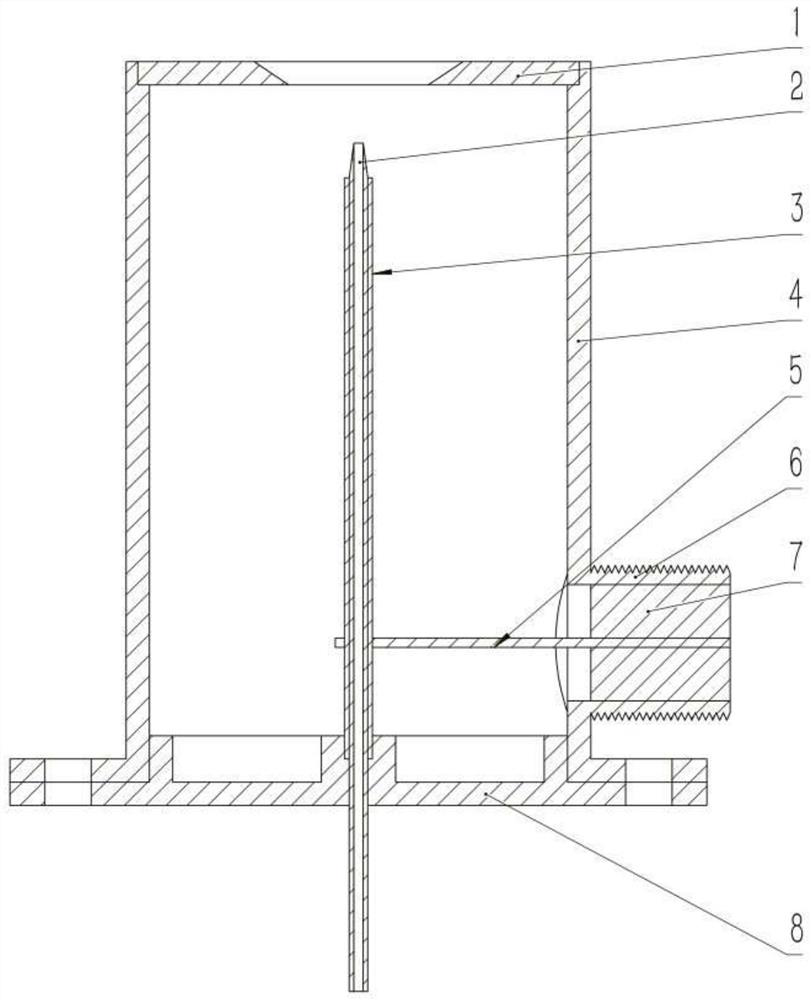

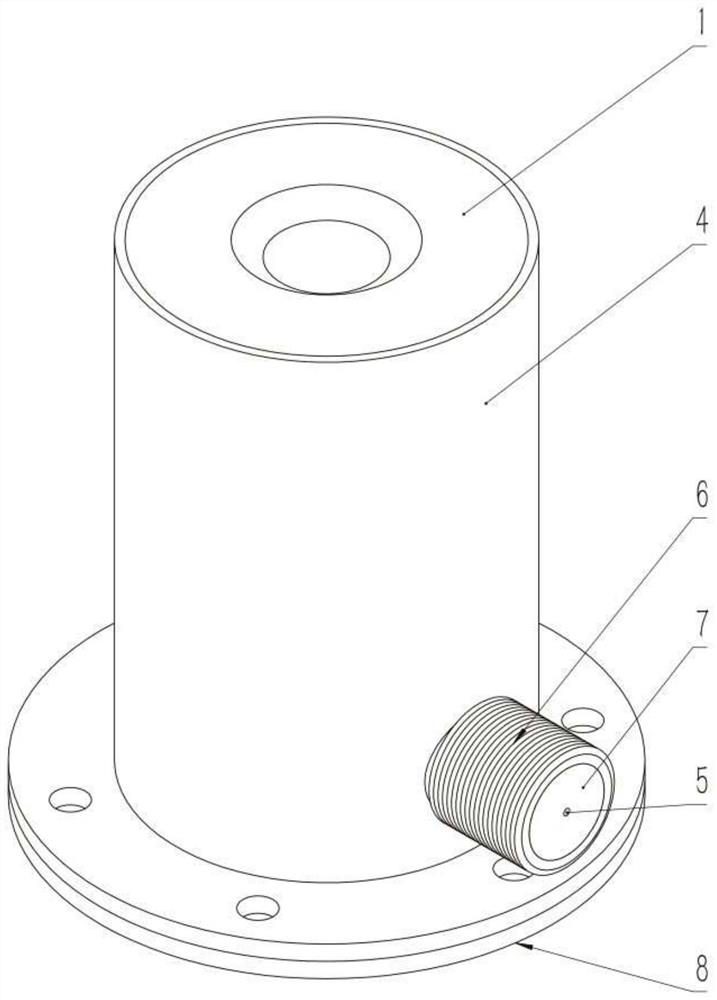

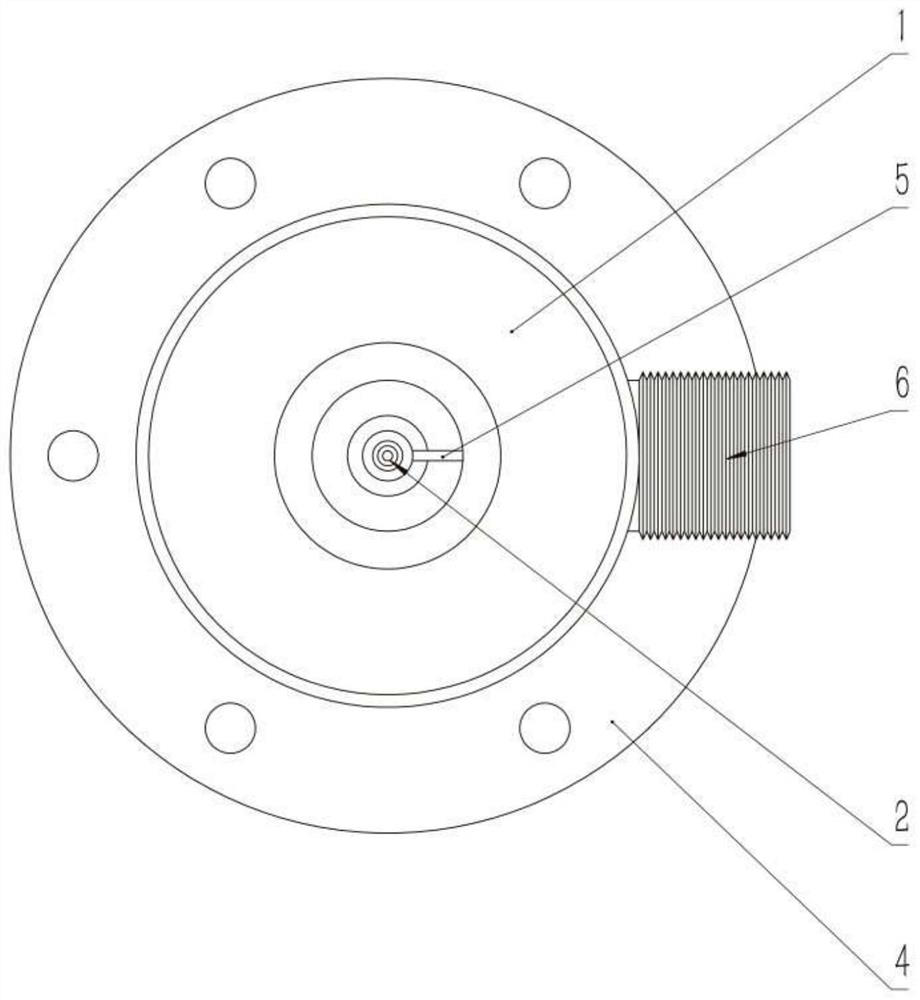

[0026] refer to Figure 1-Figure 4 As shown, a colloid thruster based on microwave enhancement is provided, including: an extraction pole 1, an emitter needle tube 2 and a base plate 8, the emitter needle tube 2 penetrates and is fixed at the center of the base plate 8, and the needle of the emitter needle tube 2 Located above the bottom plate 8, the extraction electrode 1 is located above the emitter needle tube 2,

[0027] The colloid thruster also includes: casing 3, resonant cavity shell 4, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com