Control method of garment treatment device and garment treatment device

The technology of a clothes processing device and control method is applied in the direction of washing machine control devices, washing devices, textiles and paper making, etc., which can solve the problems of increased clothes processing time, high energy consumption, and easy overloading, etc., so as to save clothes processing time, Ensure the safety of operation and improve the effect of the realization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Such as Figure 1-6 As shown, the present invention provides a control method for a clothes treatment device. The clothes treatment device includes at least two heating devices, and the power of at least one heating device is variable. The control method includes:

[0038] When the existing heating device is running and other heating devices need to be turned on, if it is judged that the sum of the heating power of the heating device that is running and the heating device that needs to be turned on exceeds the rated power, then adjust the power of the heating device with variable power so that the sum of the heating power Do not exceed rated power.

[0039] The clothes processing device has a plurality of heating devices, and may be an all-in-one washing and drying machine, or a double-tub washing machine, or the like.

[0040] By adopting the method that the power of at least one heating device is adjustable, there is room for flexibility in the total heating power of...

Embodiment 2

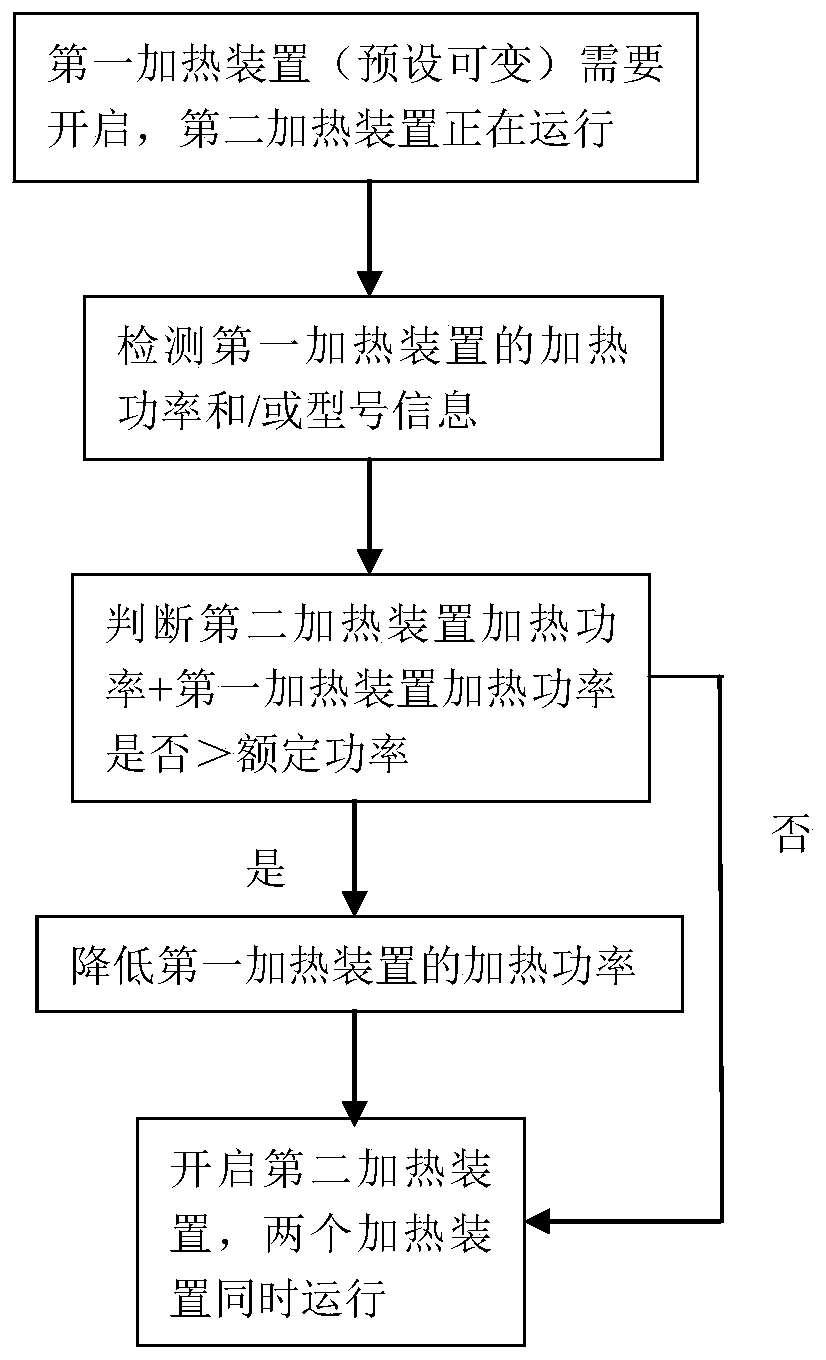

[0048] Such as Figure 1-Figure 3 As shown, this embodiment is a further limitation of Embodiment 1. The laundry treatment device provided by this embodiment includes a first heating device and a second heating device, wherein the power of the first heating device or the second heating device is variable;

[0049] When the first heating device / second heating device is running and the second heating device / first heating device needs to be turned on, if it is judged that the sum of the heating power of the first heating device and the second heating device exceeds the rated power, the first heating device will be reduced. The power of the heating device or the second heating device should be turned on after the sum of the heating power does not exceed the rated power. The first heating unit is running,

[0050] In this embodiment, the clothes treating device includes two heating devices, one of which has a variable power. The heating device with variable power can be preset, a...

Embodiment 3

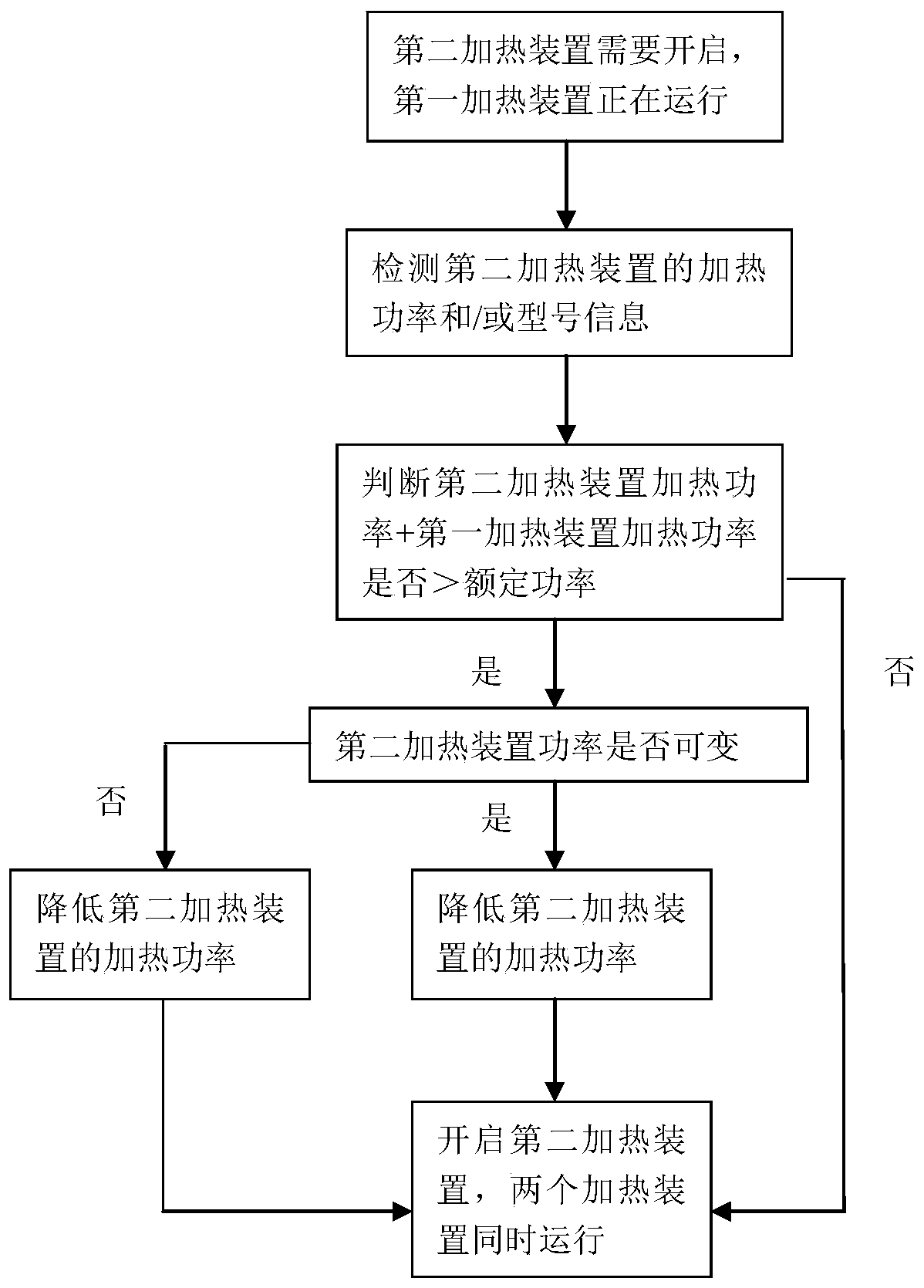

[0064] Such as Figure 4-6 As shown, this embodiment is a further limitation of Embodiment 1. The clothes treatment device includes a first heating device and a second heating device, wherein the power of the first heating device and the second heating device are variable, and the specific control method includes :

[0065] When the first heating device / second heating device is running and the second heating device / first heating device needs to be turned on, first calculate the sum of the heating power of the first heating device and the second heating device, and compare it with the rated power, If the sum of the heating power exceeds the rated power, reduce the power of the first heating device and / or the second heating device so that the sum of the heating power does not exceed the rated power and then turn it on.

[0066] In this solution, the power of the two heating devices can be changed, and more space is reserved for load adjustment. When another heating device needs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com