Intelligent twist wrap packaging equipment

A kind of packaging equipment, kink type technology, applied in the field of intelligent kink type packaging equipment, can solve the problems of candy offset, moisture will be soft, candy channel gap, etc., to reduce sliding friction, avoid jamming, effective opening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

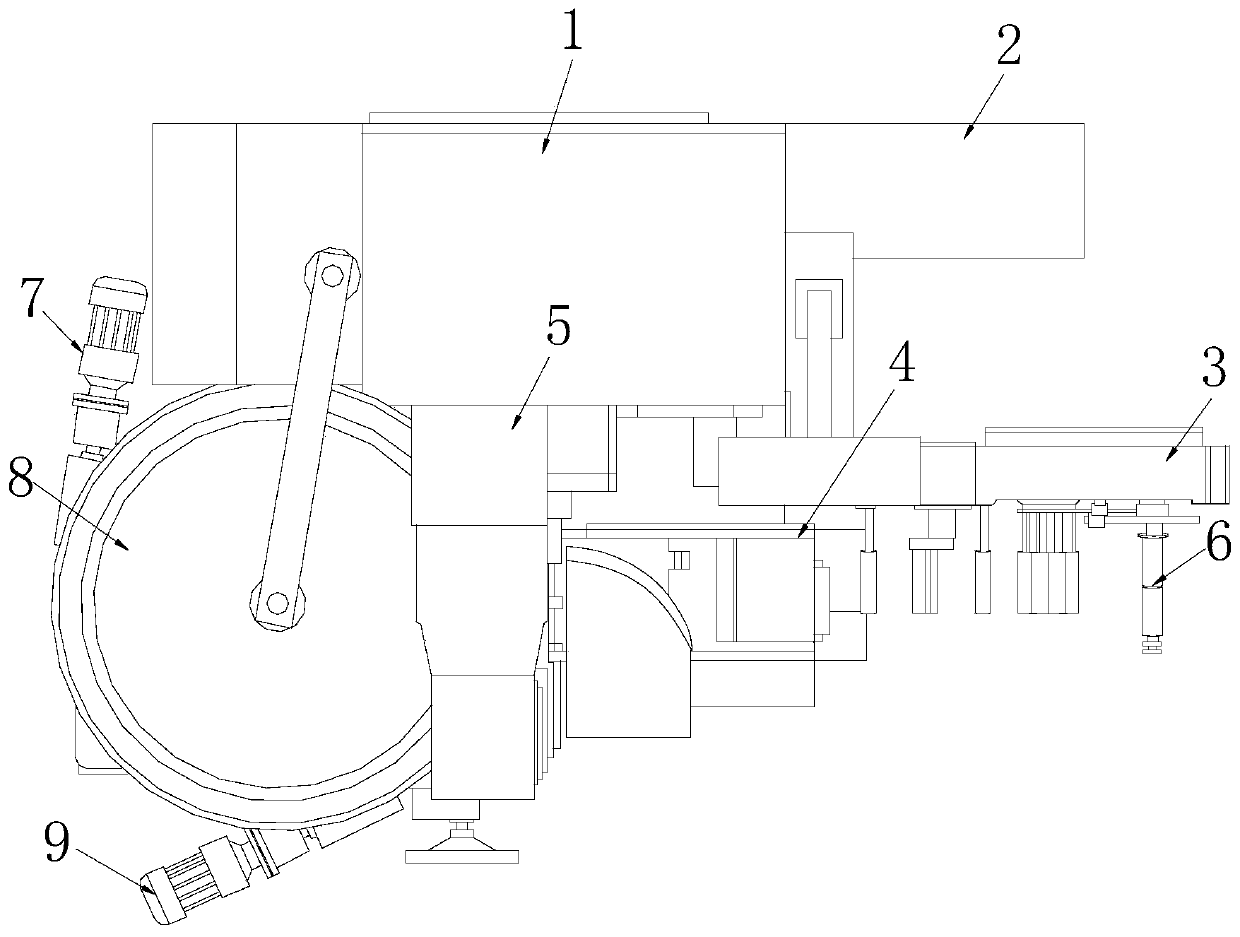

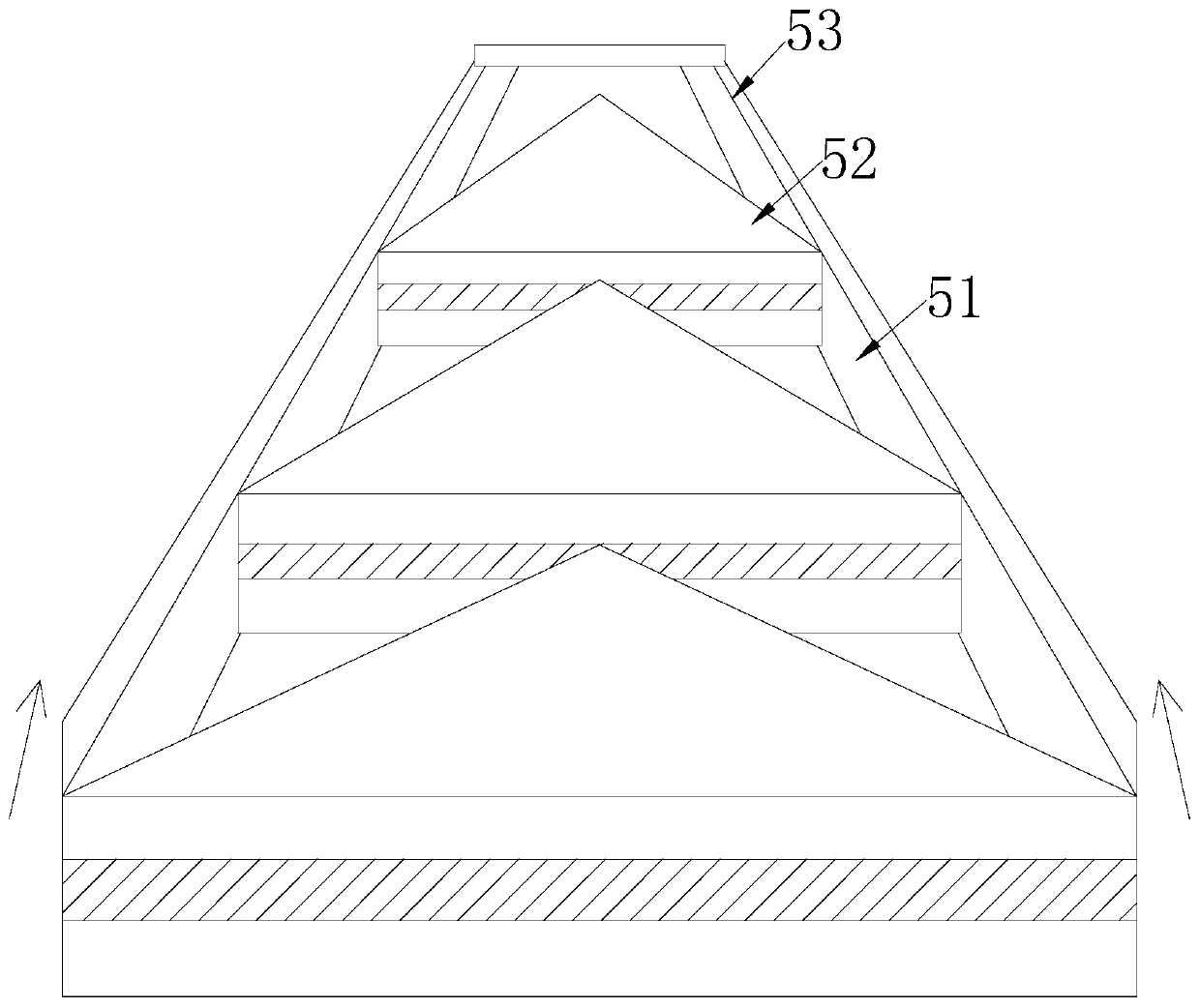

[0029] like Figure 1-Figure 4 As shown, the present invention provides a kind of intelligent twist packaging equipment, its structure includes main box 1, process tray 2, paper feeding table 3, folding board 4, packaging table 5, paper feeding roller 6, first sugar sorting motor 7 , take over plate 8, the second sugar sorting motor 9, the main box 1 controls the process plate 2 and the first sugar sorting motor 7, the second sugar sorting motor 9, the first sugar sorting motor 7, the second sugar sorting motor 9 is matched with the receiving tray 8, the output port of the receiving tray 8 is matched with the packaging table 5, the paper feeding roller 6 is connected with the folding board 4, and the paper feeding roller 6 is provided with more than two and installed on the feeding On the paper table 3, the paper feeding table 3 is driven by the main box 1 to cooperate with the packaging table 5. The inside of the packaging table 5 and the candy outlet of the receiving tray 8 ...

Embodiment 2

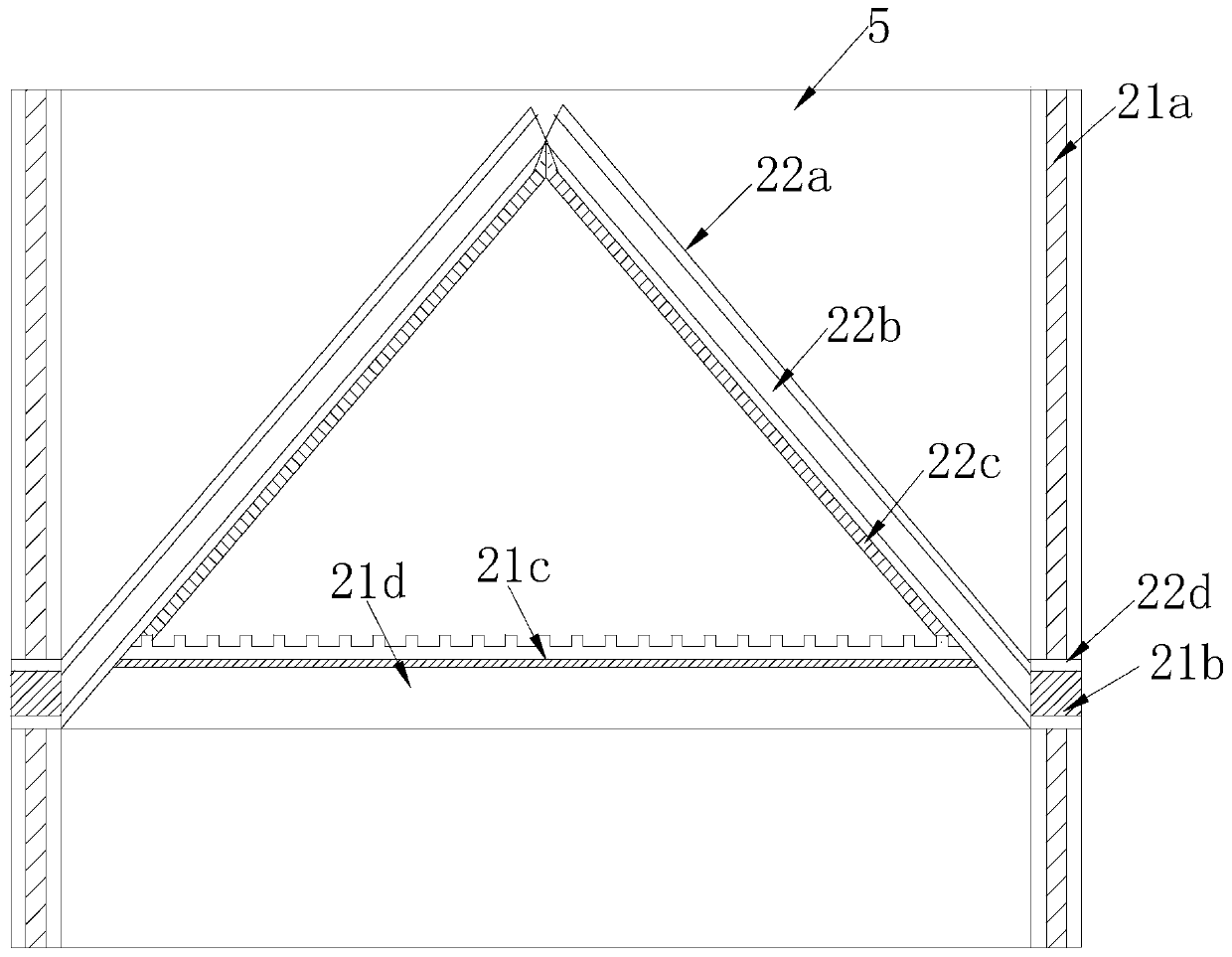

[0031] like Figure 5-Figure 6 As shown, on the basis of Embodiment 1, the push plate 21d is provided with a position sensor 1d1, a driver 1d2, a slot 1d3, a connection block 1d4, and a negative magnetic pole piece 1d5, and the signal input terminal of the position sensor 1d1 is connected to the driver The 1d2 signal terminal is electrically connected, the driver 1d2 drives the sliding interface 21b, the slot 1d3 is embedded in the slant plate 22a, the slot 1d3 is fixed with the push plate 21d through the connecting block 1d4, and the slot 1d3 faces the slant plate One end of 22a is fixed to the negative magnetic pole piece 1d5, and is embedded in the inner card slot 22b. The inner card slot 22b is matched with the positive magnetic pole piece 2b1 and the soft side 2b2, and the positive magnetic pole piece 2b1 and the negative magnetic pole piece 1d5 are magnetically adsorbed and fixed. A soft edge 2b2 is provided at the position where the positive magnetic pole piece 2b1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com