Oil seal press-mounting device

A press-fitting device and oil seal technology, applied in measuring devices, optical devices, instruments, etc., can solve problems such as oil leakage, engine oil leakage, and installation accuracy cannot be guaranteed, so as to improve detection efficiency, ensure assembly accuracy, and improve equipment. Efficiency effect of overhaul adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

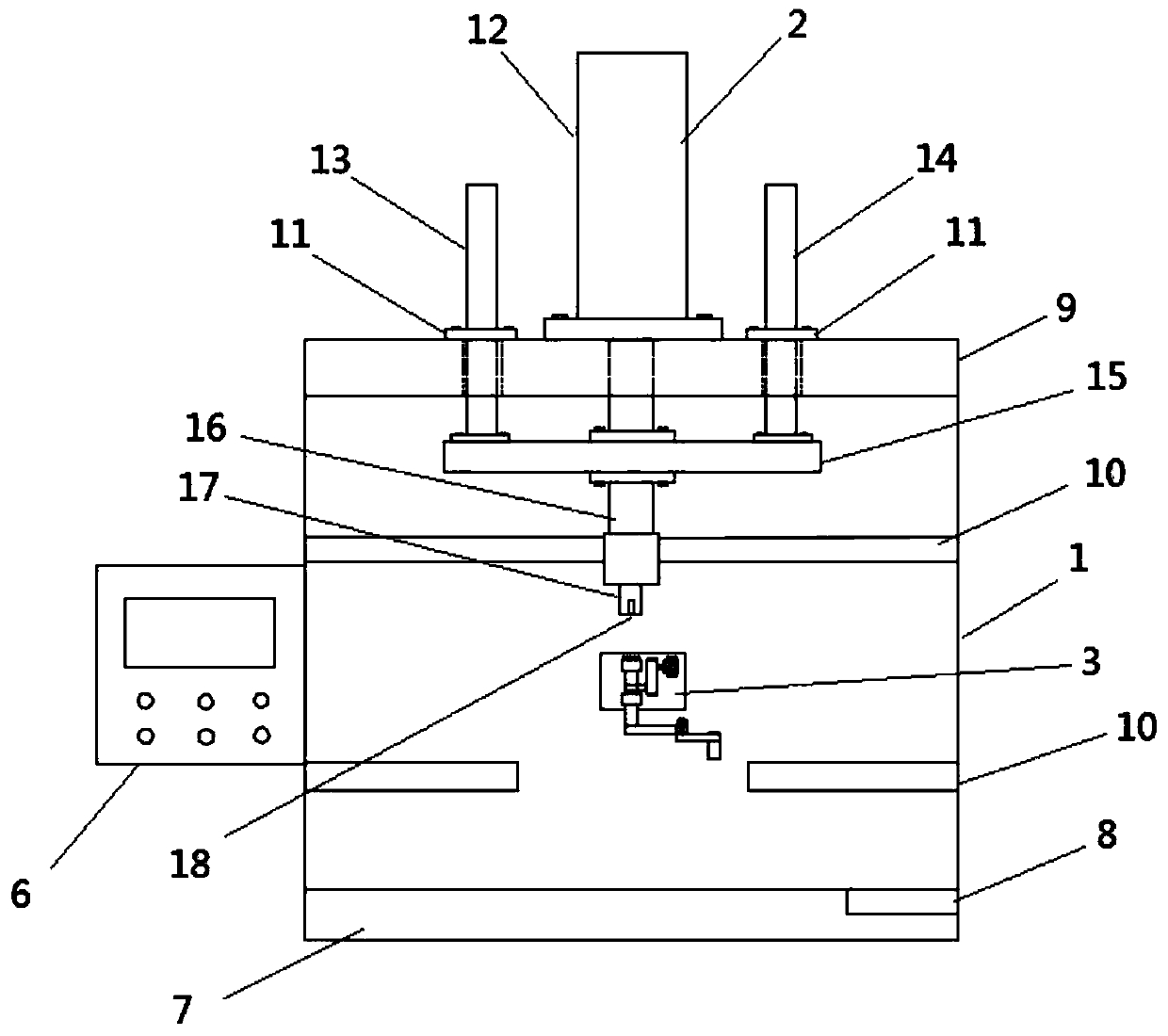

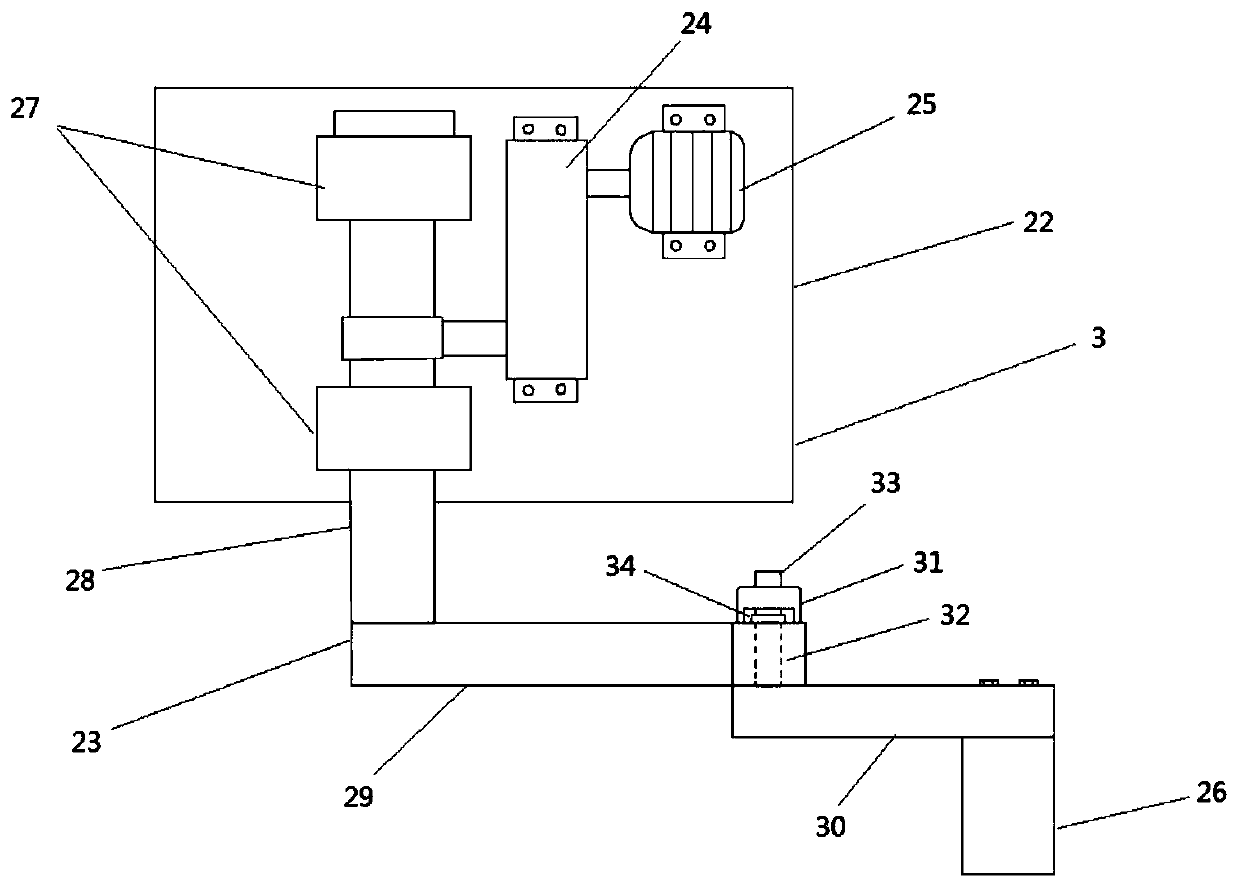

[0027] Such as Figure 1-10As shown, an oil seal press-fitting device is characterized in that: a support frame 1, a press-fit component 2, a flatness detection component 3, a pressing block 4, a check block 5, and a controller 6. The bottom of the support frame 1 is provided with The workpiece table 7 is used to place parts that need to be press-fitted with oil seals. The right part of the workpiece table 7 is provided with a rubber block 8. The right part of the support frame 1 is equipped with a conveyor belt, and the parts on the conveyor belt are directly transferred to the workpiece table 7. , the rubber block 8 can play a buffering role to prevent parts from being damaged. The top of the support frame 1 is provided with a press-fit table 9 for installing the press-fit assembly 2. The middle part of the support frame 1 is provided with a placement table 10 for use In order to place pressure blocks 4 of various specifications for easy replacement, limit sleeves 11 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com