Papermaking sewage efficient treatment device

A technology for treating equipment and papermaking sewage, which is applied in filtration and separation, separation methods, mobile filter element filters, etc., can solve the problems of inability to purify the discharge of pond sediment, inability to treat quickly, and low degree of purification, saving money and improving Cleaning effect, high purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

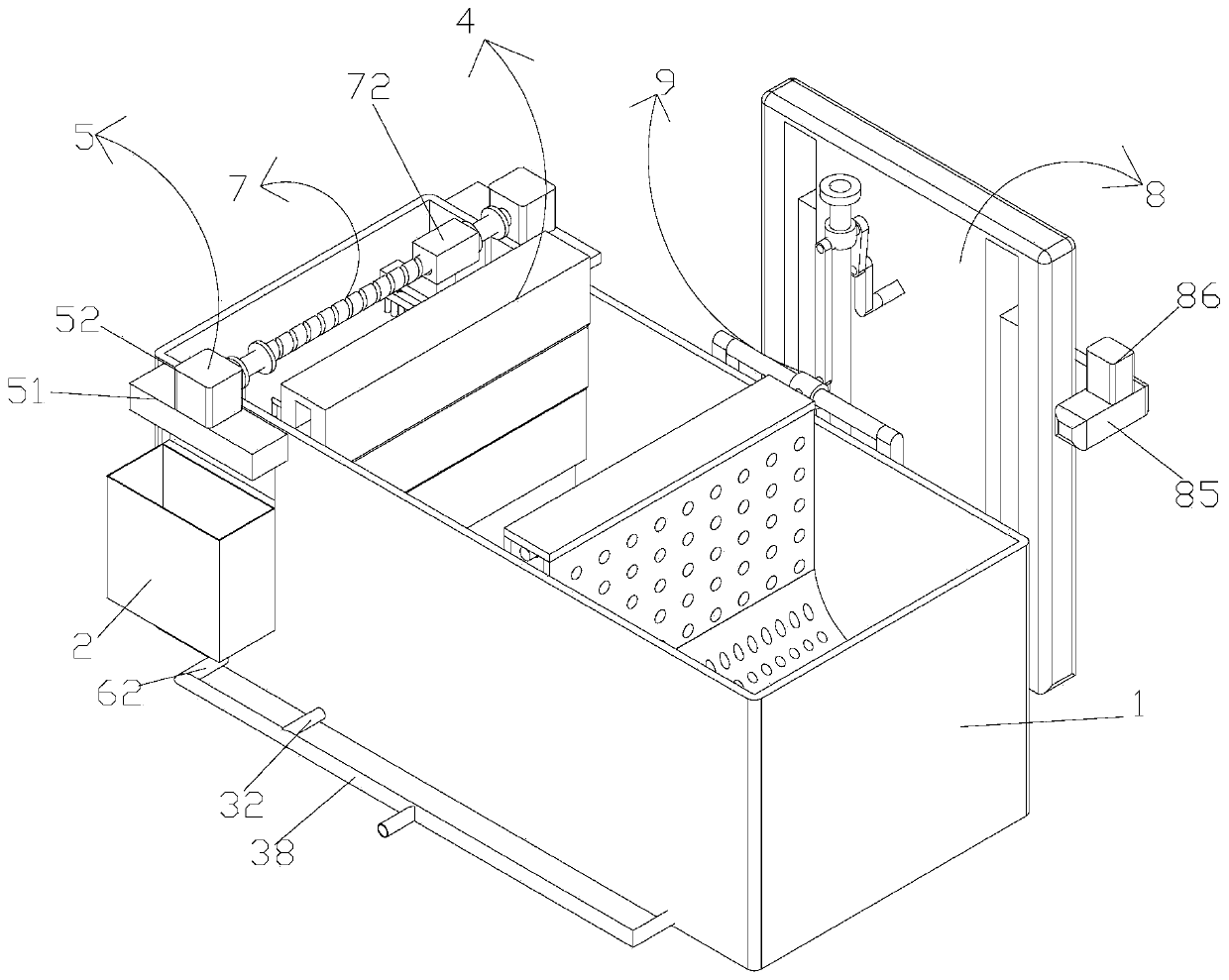

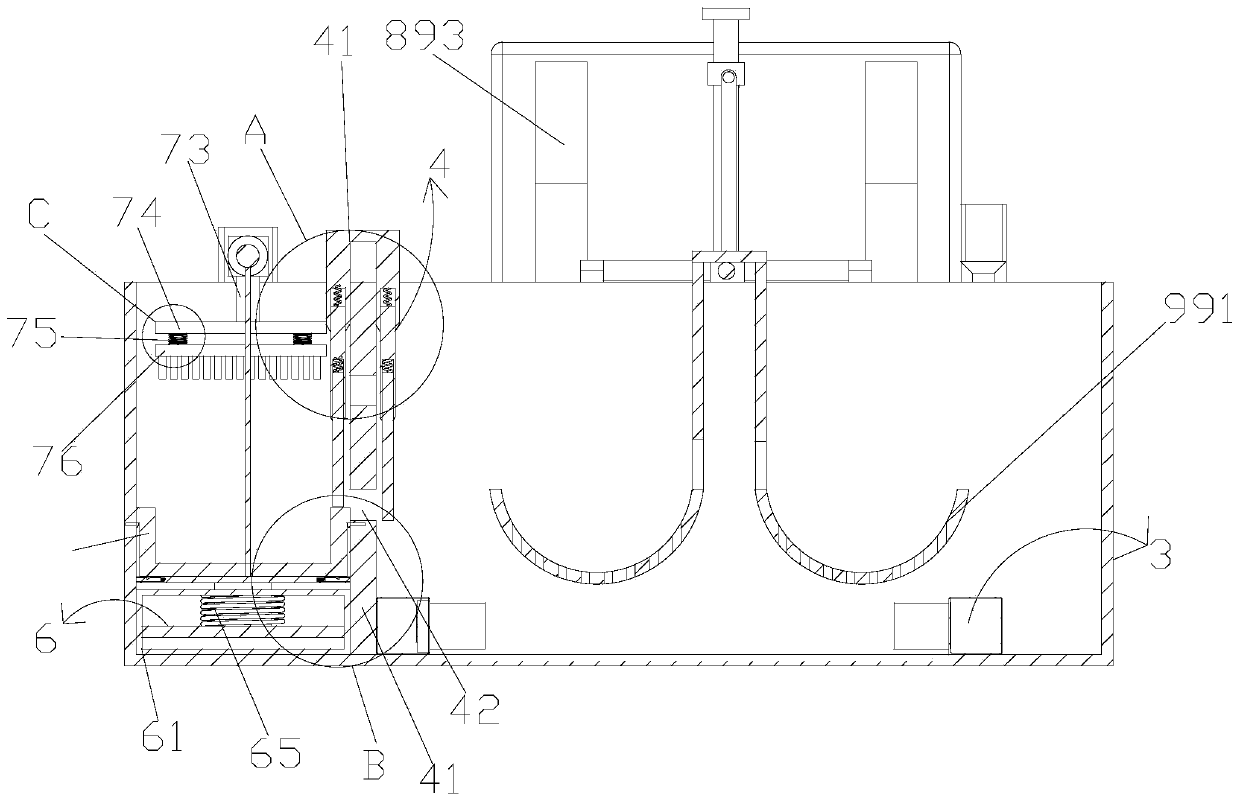

[0036] Such as Figure 1-12 As shown, a high-efficiency papermaking sewage treatment device includes a sewage treatment tank 1, a garbage collection tank 2, a pre-screening device 5, a baffle 4, and a salvage device 3; the garbage collection tank 2 is located at the front left of the sewage treatment tank 1 The upper side is fixedly connected; the pre-screening device 5 is located on the left side of the sewage treatment tank 1; the baffle 4 is located in the sewage treatment tank 1, and the bottom of the baffle 4 is fixedly connected to the bottom of the sewage treatment tank 1; the salvage The device 3 is located on the right side of the baffle plate 4 .

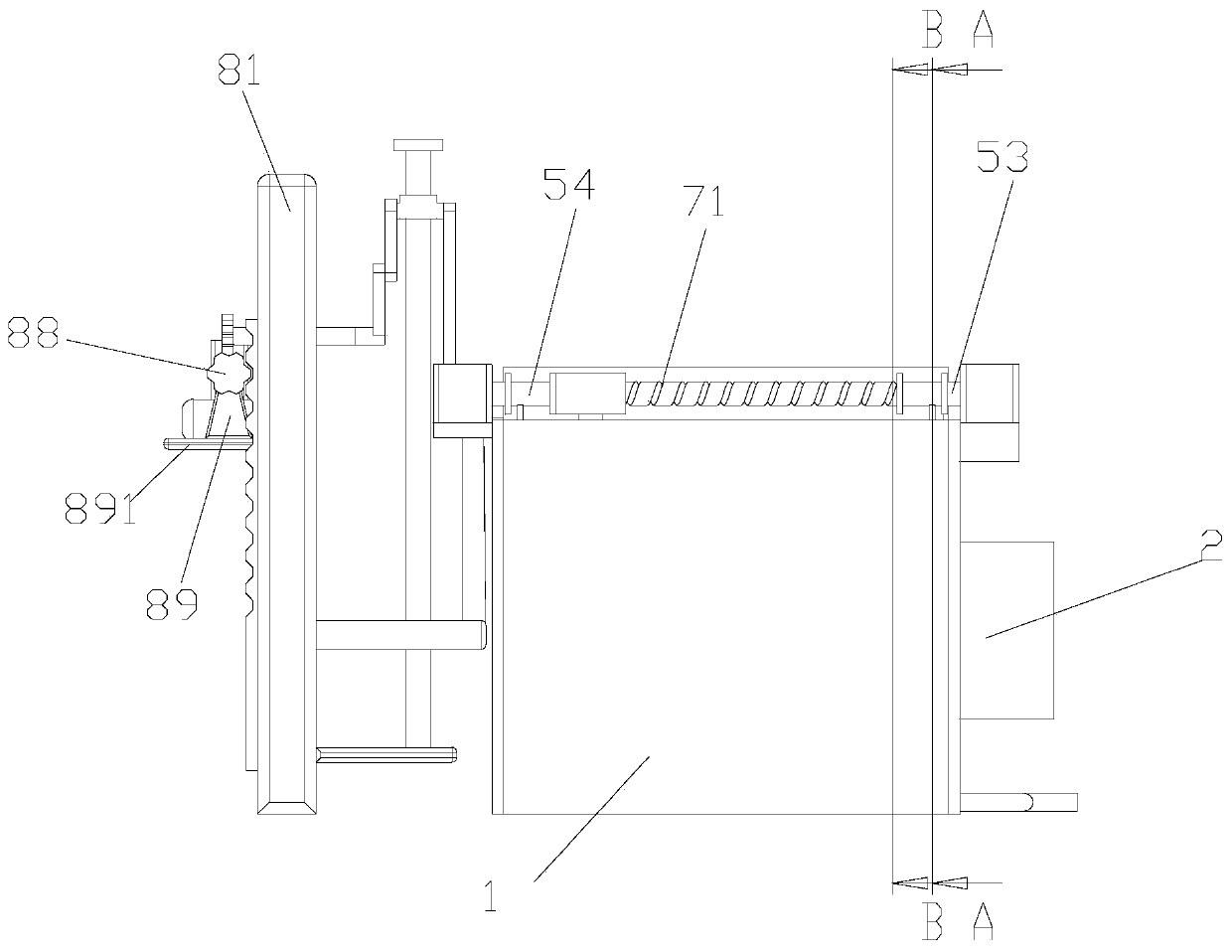

[0037] Such as Figure 1-2 As shown, the pre-screening device 5 includes a support plate 51, a first motor 52, a rotating shaft 53, a drum 54, a wire rope 55, a connecting seat 56, a slider 57, a mesh 58 and a lifting device 6; the number of the support plate 51 There are 2 pieces, which are fixedly connected to the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com