Microemulsion and preparation method thereof

A technology of microemulsion and emulsifier, which is applied in the field of daily chemicals, can solve the problems of high process cost, high irritation of microemulsion, and limited application, and achieve the effect of less dosage, less irritation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

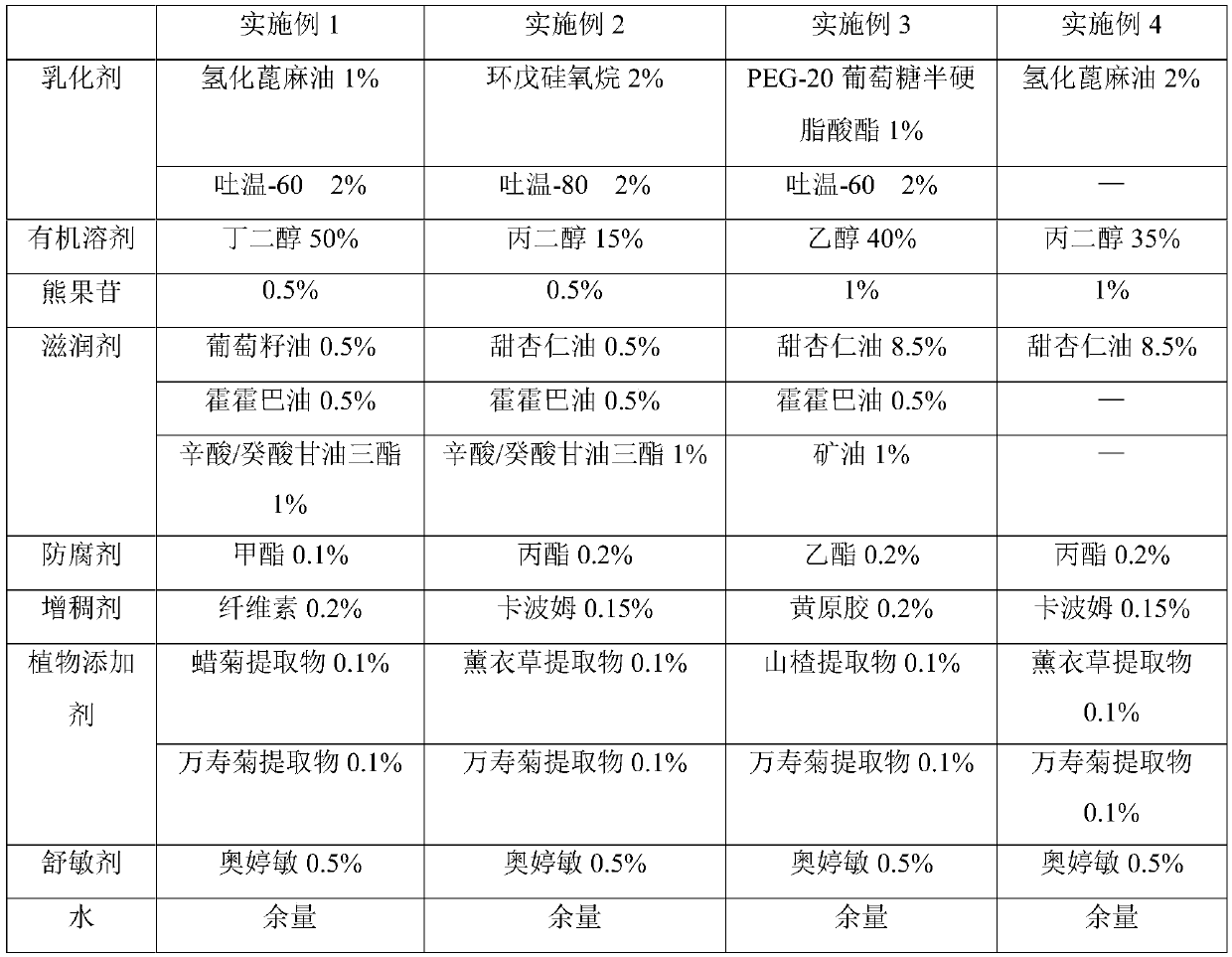

Examples

Embodiment Construction

[0021] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0022] A microemulsion comprises the following components in parts by weight: 35-77 parts of water, 2-4 parts of emulsifier, 15-50 parts of organic solvent and 0.5-1 part of arbutin.

[0023] In the field of daily chemicals, water, emulsifier and organic solvent are mixed. Based on the properties of both hydrophilic and lipophilic emulsifiers, the three can form a stable emulsion system after high-speed stirring, and the dispersion is relatively uniform, but not transparent; In order to obtain a transparent microemulsion system, it is necessary to increase the amount of emulsifier. However, as the amount of emulsifier increases, the irritation increases and the scope of use is limited.

[0024] Wherein, the emulsif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com