A biopharmaceutical capsule filling device

A biopharmaceutical and filling device technology, which is applied in capsule delivery, pharmaceutical formulation, drug delivery, etc., can solve problems such as increased cost, increased production rate, and production troubles, so as to reduce production cost, reduce defective rate, and be practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

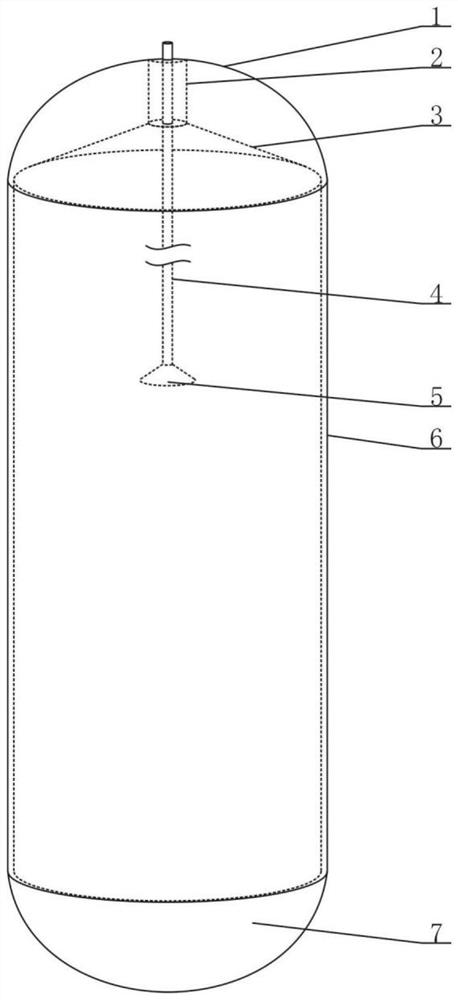

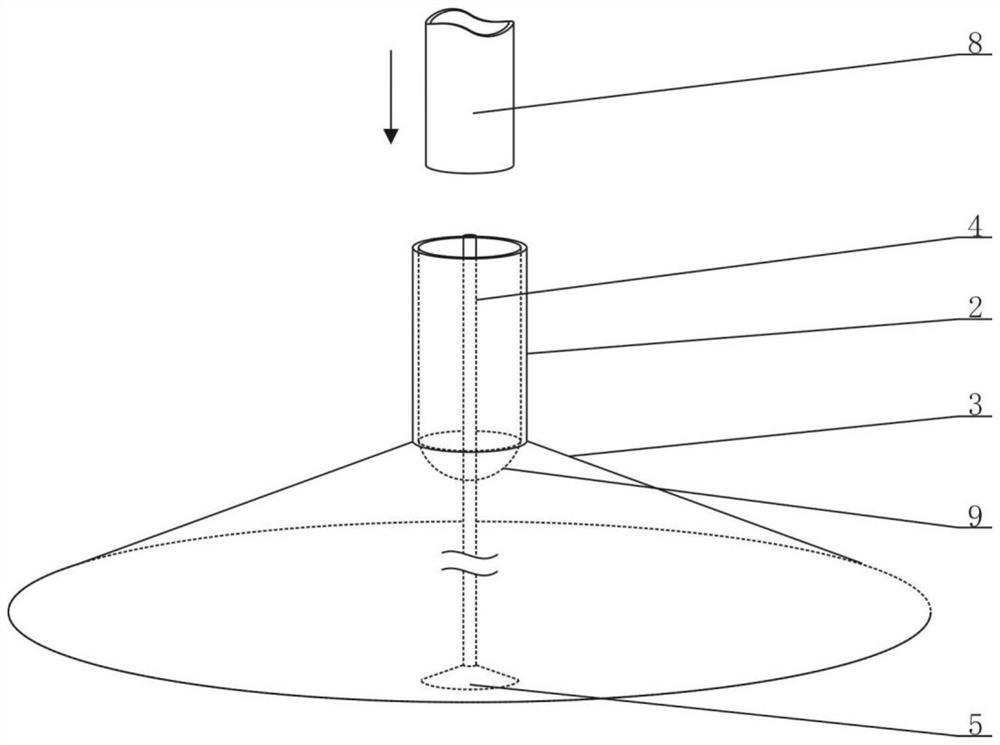

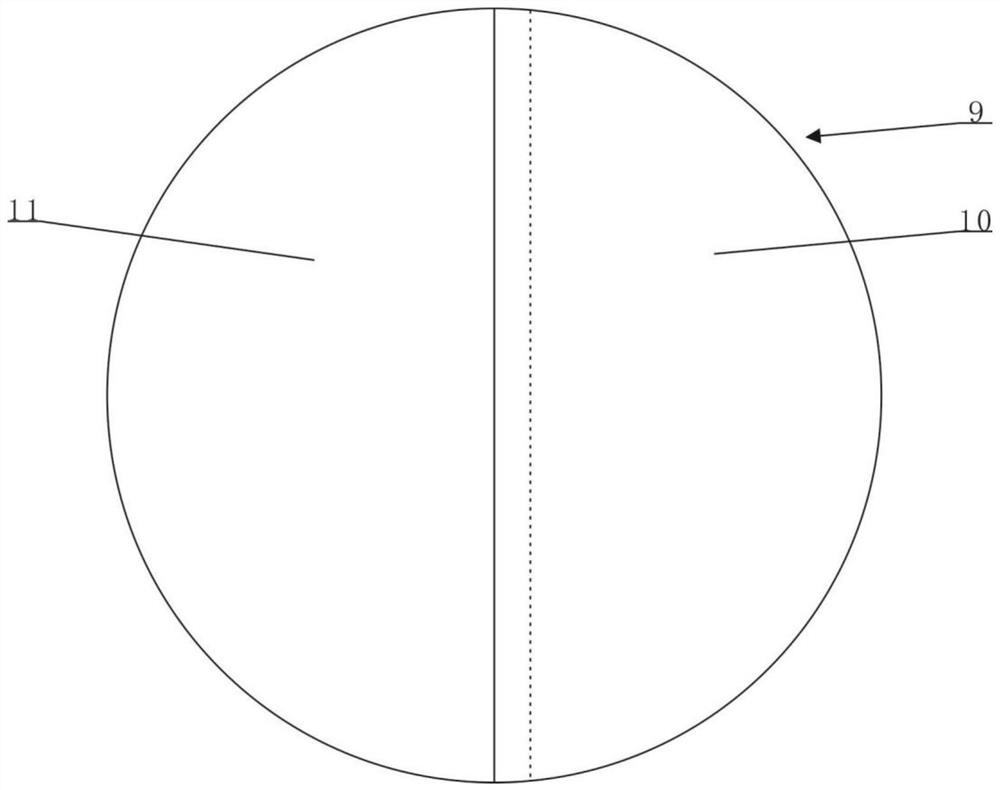

[0018] combined with Figure 1~3 A biopharmaceutical capsule filling device, comprising a first capsule head 1, a capsule body 6, a second capsule head 7, a drug feeding tube 2, a pull rod 4, a medicine sealing disc 3, a sealing gasket 5 and a sealing film 9, and the capsule body 6 The first bag head 1 and the second bag head 7 are arranged on the top, the first bag head 1 or the second bag head 7 is provided with a drug feeding tube 2, and the drug feeding tube 2 is provided with a sealing film 9 and a drug sealing plate 3, A pull rod 4 is arranged inside the medicine feeding tube 2 , and the pull rod 4 passes through the sealing membrane 9 and is connected with the sealing gasket 5 in the capsule body 6 .

[0019] The capsule body 6 is a cylindrical ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com