A wire insulation layer fuse device suitable for different wire diameters

A wire insulation and fusing technology, applied in the direction of line/collector parts, electrical components, connections, etc., can solve the problem that the insulation layer of the wire cannot be effectively contacted with the jaws, which is not conducive to the precise melting of the insulation layer of the wire, and the repeatability of stripping Time-consuming work and other problems, to achieve the effect of simple structure, high versatility, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] A wire insulation layer fusing device suitable for different wire diameters proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

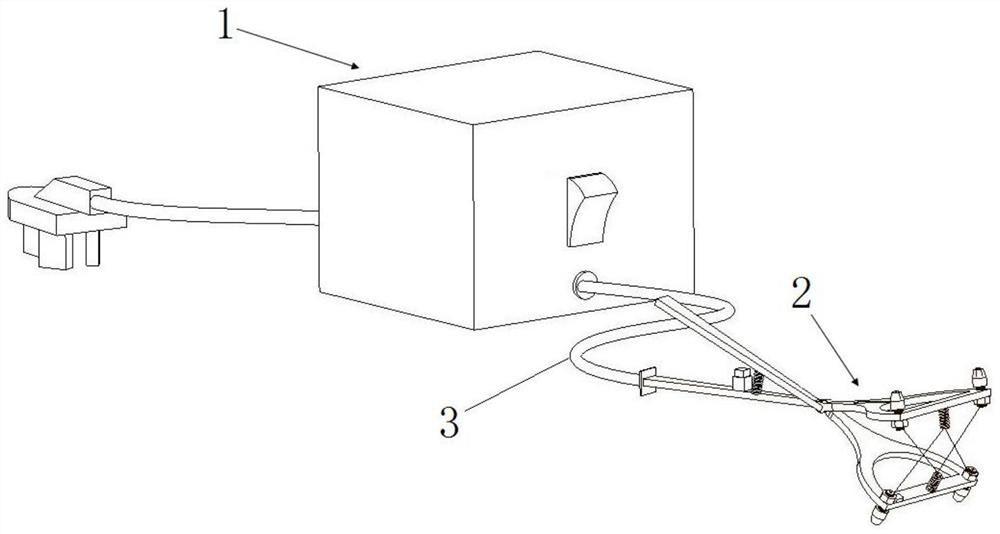

[0066] The present invention is applicable to a wire insulating layer fusing device with different wire diameters, such as figure 1 As shown, it includes a control unit 1, a wire stripping head 2 and a connecting wire 3 arranged between the control unit 1 and the wire stripping head 2, and the control unit 1 is connected to a power supply.

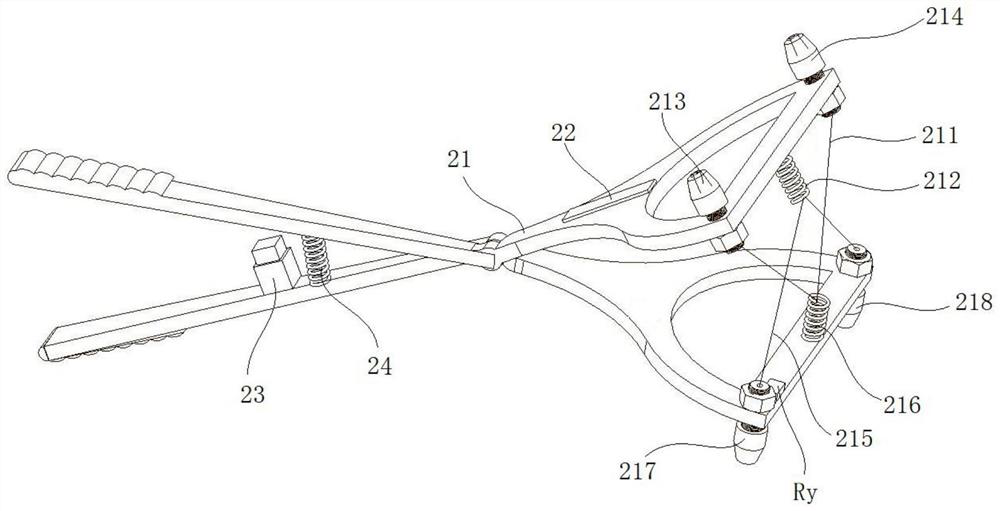

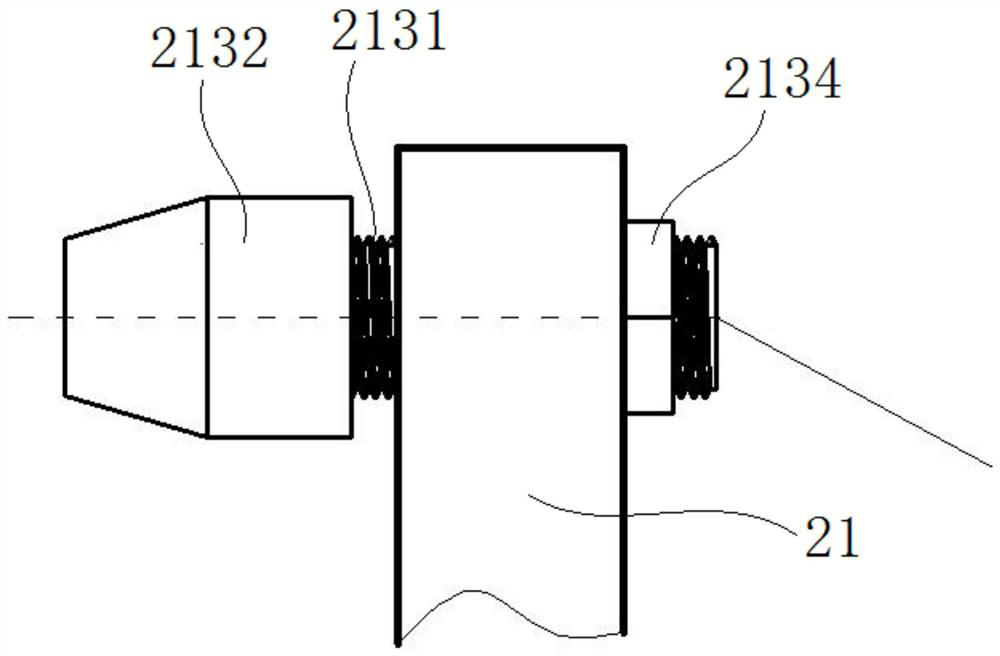

[0067] Among them, stripping head 2 such as figure 2 As shown, it includes two V-shaped clamping parts, and the hinges of the two clamping parts are hinged to form an X-shaped clamping frame 21. One end of the clamping frame 21 is two handles for holding, and the other end is It is a jaw used for heat-removing the insulation layer of the wire. When the two handles are held together, the jaw will expand.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com