Garden road construction equipment

A technology for road construction and gardening, applied in the field of garden road construction equipment, can solve the problems such as the failure of the curing film to fit, the cracking of the concrete surface, and the imperfect technology, and achieve the effects of improving the strength, increasing the load, and reducing the occupied area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

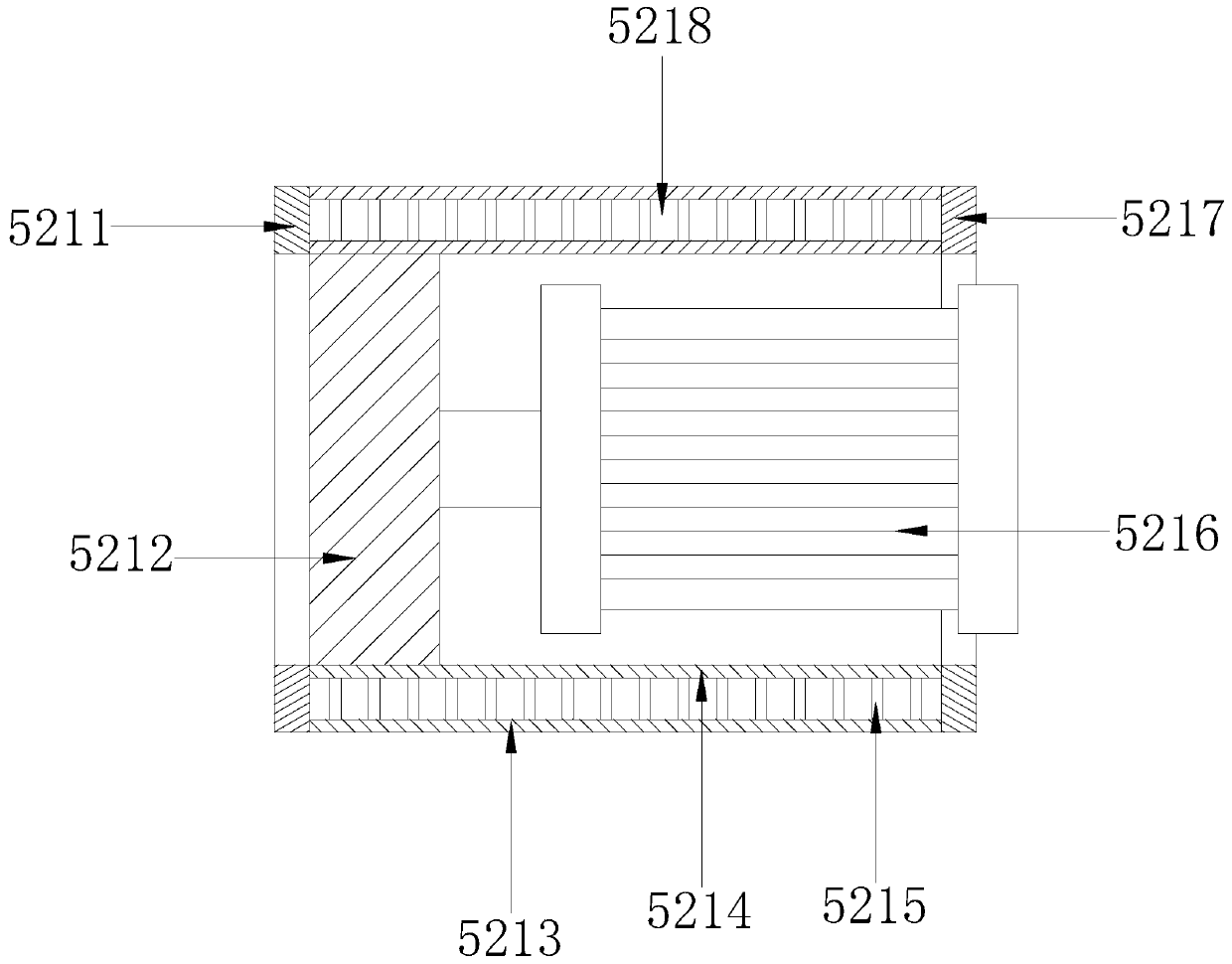

[0040] see figure 1 , the present invention provides a technical solution for garden road construction equipment: please refer to figure 1, the present invention provides a technical solution for garden road construction equipment: its structure includes a lithium battery assembly 1, a U-shaped armrest frame 2, a coating frame 3, a maintenance coating tube 4, a defoaming device 5, a flattening rod 6, Alloy vibrating rod 7, vibrator 8, the film covering frame 3 is vertically connected with a U-shaped armrest frame 2, a lithium battery assembly 1 is fixed on the U-shaped armrest frame 2, and a The alloy vibrating rod 7 mechanically connected with the film covering frame 3, the alloy vibrating rod 7 is provided with a vibrator 8, and the film covering frame 3 is sequentially connected with mutually parallel flattening rods 6 from the outside to the inside. Bubble device 5, maintenance coating cylinder 4, the setting of described flattening bar 6 is to can carry out longitudina...

Embodiment 2

[0047] see figure 1 , the present invention provides a technical solution for garden road construction equipment: its structure includes a lithium battery assembly 1, a U-shaped armrest frame 2, a coating frame 3, a maintenance coating tube 4, a defoaming device 5, a flattening rod 6, Alloy vibrating rod 7, vibrator 8, the film covering frame 3 is vertically connected with a U-shaped armrest frame 2, a lithium battery assembly 1 is fixed on the U-shaped armrest frame 2, and a The alloy vibrating rod 7 mechanically connected with the film covering frame 3, the alloy vibrating rod 7 is provided with a vibrator 8, and the film covering frame 3 is sequentially connected with mutually parallel flattening rods 6 from the outside to the inside. Bubble device 5, maintenance coating cylinder 4, the setting of described flattening bar 6 is to can carry out longitudinal flattening to concrete curing film, makes concrete curing film can fit well with concrete, prevents concrete curing fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com