Grooved wheel type intermittent feeding and discharging automatic gluing device

A technology of gluing device and sheave, which is applied to the device for coating liquid on the surface, coating, transportation and packaging, etc. It can solve the problems of difficult control of gluing quality, low work efficiency and high labor intensity, and achieve saving The effects of purchase cost, trouble-free operation, and trouble-free maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

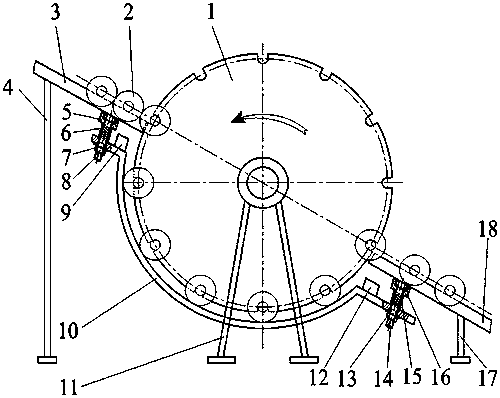

[0020] figure 1 with figure 2 It is an embodiment disclosed in the present invention. The grooved wheel type intermittent loading and unloading automatic gluing device of the present invention consists of a grooved wheel turntable 1, a single-track rolling feeder 3, a feeder support 4, a glue dispenser 9, an arc-shaped rubber coating board 10, a turntable support 11, The glue collector 12, the single-track rolling lower forehead 18, the lower forehead bracket 17, the upper position adjustment mechanism, the lower position adjustment mechanism, etc. are assembled. The upper position adjustment mechanism includes: upper sealing plate 5, upper spring 6, upper fine adjustment Nut 7, upper adjusting bolt 8, lower distance adjusting mechanism includes: lower sealing plate 16, lower spring 15, lower fine adjusting nut 13, lower adjusting bolt 14.

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com