Sealing method for performing single sealing on packaging bag by using vacuum sealing machine

A technology of vacuum sealing and packaging bags, applied in the direction of packaging, packaging sealing/tightening, and packaging under vacuum/special atmosphere, it can solve the problems of unavoidable wrinkles or indentations of packaging bags, and achieve fast and efficient sealing, tight sealing, Melting uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

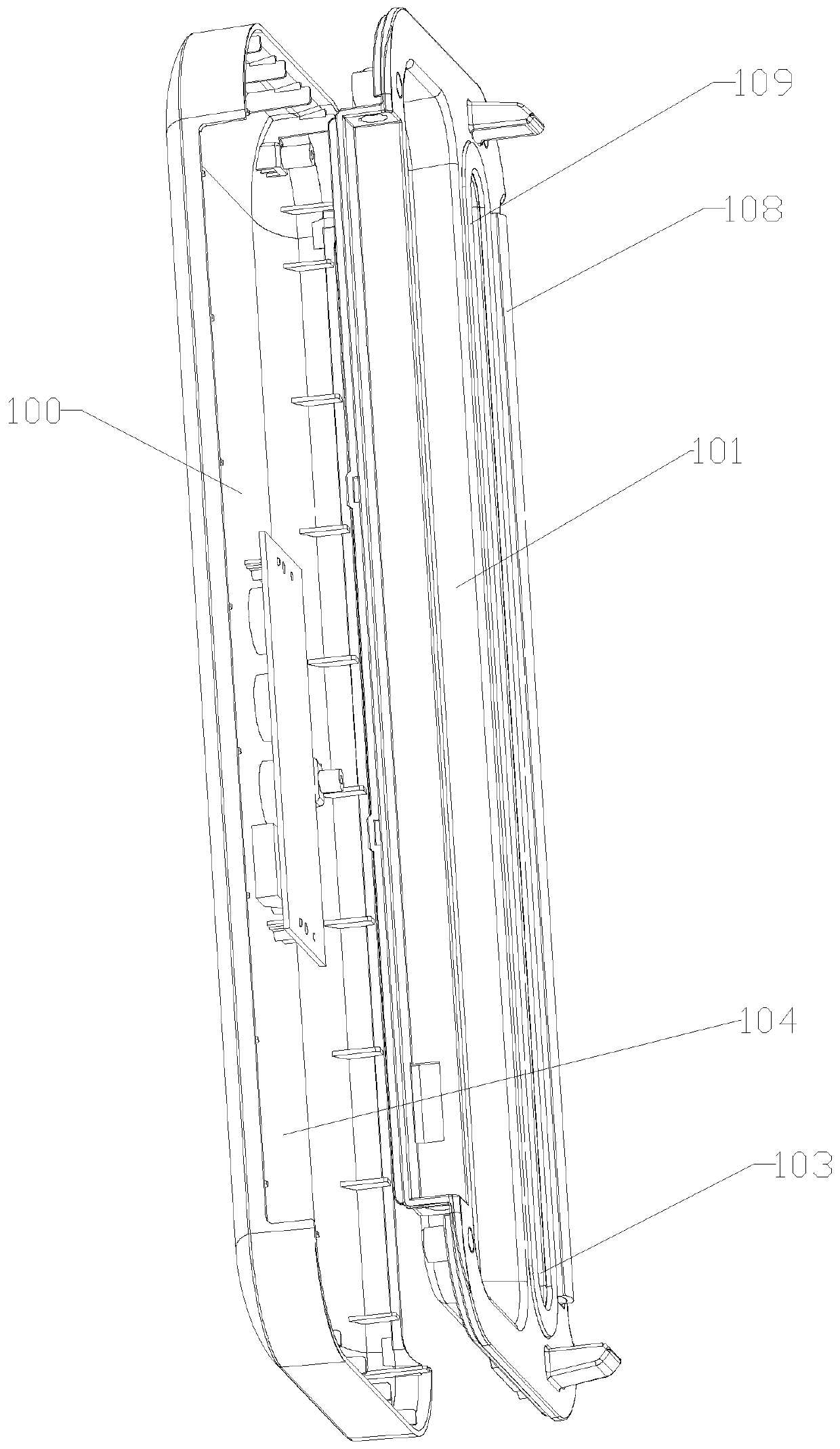

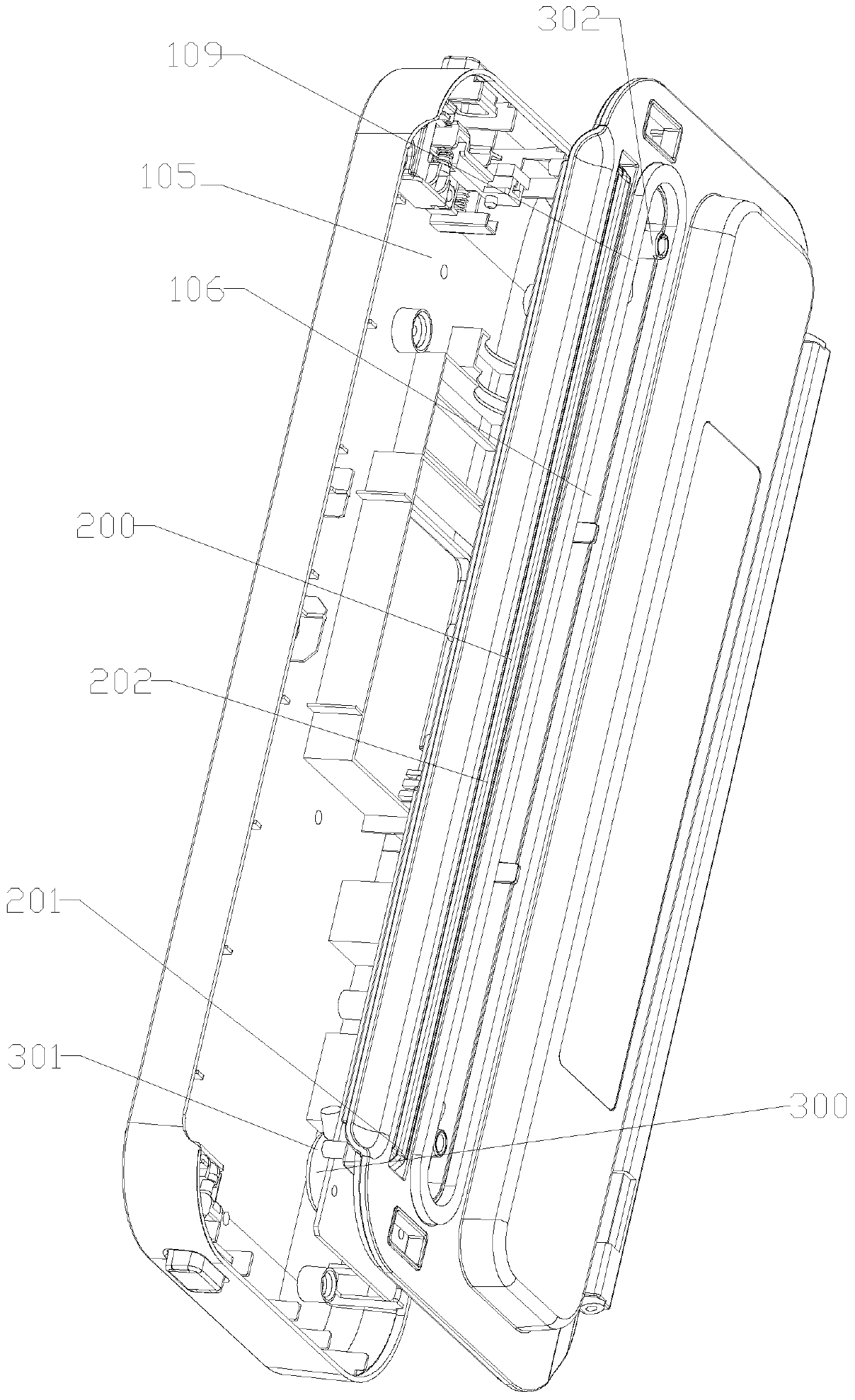

[0040] This embodiment provides a sealing machine with a vacuum function, and a method for individually sealing a packaging bag with the sealing machine. like Figure 1 to Figure 3 As shown, the sealing machine specifically includes a cover assembly 100, the cover assembly includes an upper cover assembly 101 and a lower cover assembly 102 hinged to each other, the upper cover assembly is closed above the lower cover assembly, and the upper cover assembly includes An upper cover and a top cover, the top cover is provided with a button panel, the top cover is closed above the upper cover, and the upper cover and the top cover form an upper accommodation cavity 104, and the lower cover assembly 102 includes a lower cover and a base , the lower cover plate and the base form a lower accommodation cavity 105 . The cover plate assembly is provided with a control board, a heat sealing device 200 and a vacuuming device 300 electrically connected to the control board. The part of the...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that the execution time nodes of the sealing step and the pretensioning step are different. In this embodiment, the sealing step and the preloading step are carried out sequentially:

[0055] That is to say, the sealing step is first started and executed for a time t1, and then stopped, and the preloading step is restarted and executed for a time t2. In this embodiment, after the sealing step is stopped, the preloading step is started immediately , and t1 is 11s, and t2 is 4s. This setting can reduce the problems of unstable operation and high power caused by the simultaneous operation of the vacuuming device and the heat sealing device, thereby improving the sealing effect and making the whole machine more energy-saving and environmentally friendly when performing single-sealing functions.

[0056] It can be understood that the sealing step is first started and executed for a time t1, and then stopped, and the...

Embodiment 3

[0060] As a third embodiment of the present invention, the sealing method includes:

[0061] In the starting step, the user puts the materials to be sealed and stored into the packaging bag, opens the upper cover assembly of the sealing machine, places the mouth of the packaging bag on the heat sealing device, closes the upper cover assembly and starts the single Sealer.

[0062] In the pre-pressing step, the control board controls the vacuuming device to perform a vacuuming action, so as to pre-press the cover plate assembly and the packaging bag. Further, the execution time of the pre-pressing step is t6, 0.1s≤t6≤4s, as a preference, in this embodiment, t6 is 1s, the pre-pressing step starts before the sealing step, and the vacuum pumping in the pre-pressing step The device starts for 1 second to pre-tighten the mouth of the packaging bag, and pre-adjusts the position of the sealing position of the packaging bag. The packaging bag is placed in an accurate position and can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com