Battery replacing station and control method thereof

A control method and power station technology, which is applied to charging stations, electric vehicles, electric vehicle charging technology, etc., can solve the problems of low power exchange efficiency in power stations and low space utilization in charging rooms, and avoid repeated placement of batteries, The effect of improving space utilization and improving power exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

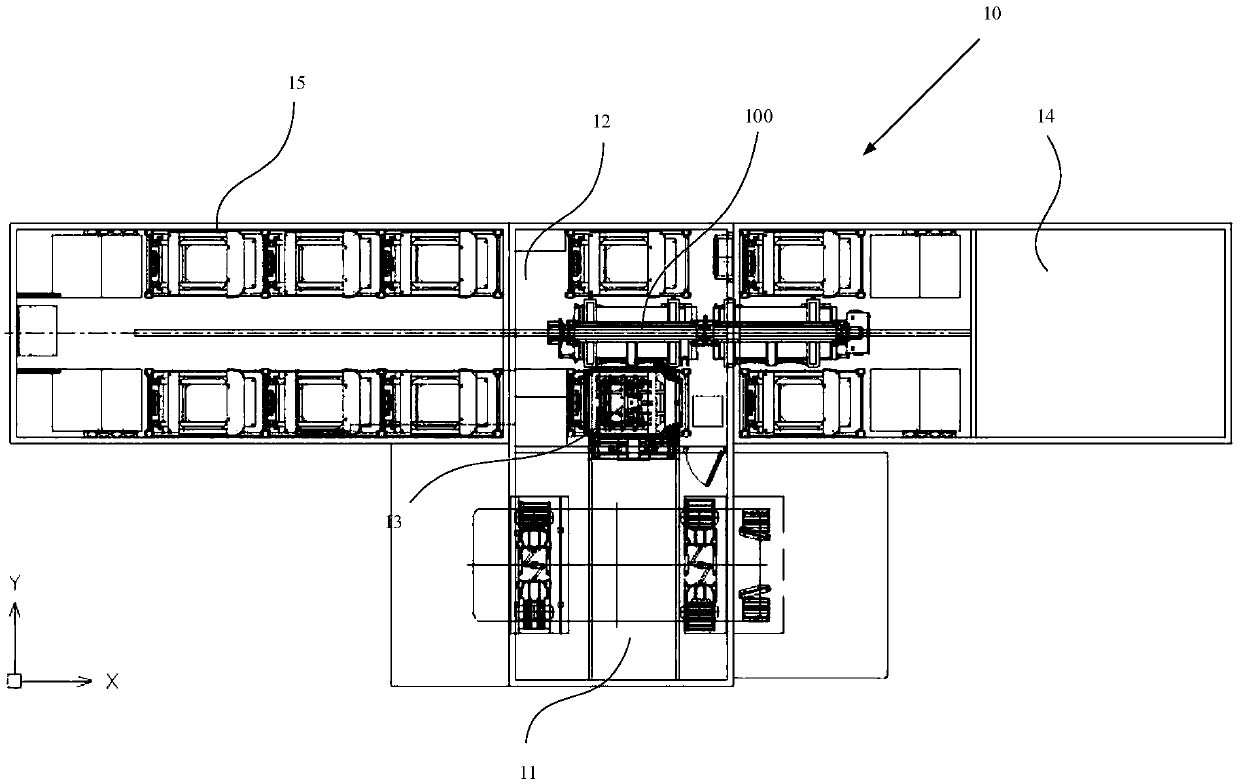

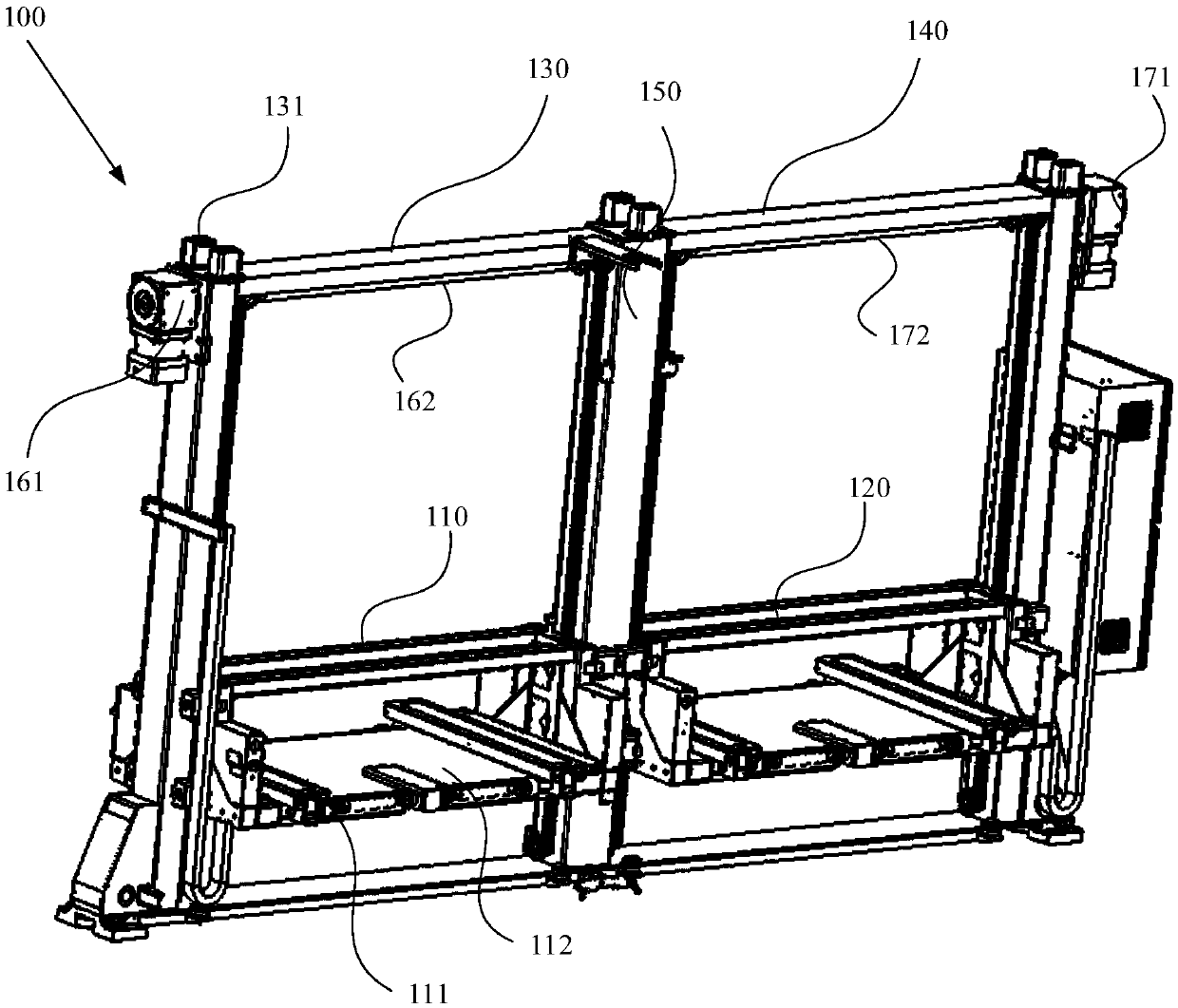

[0077] figure 2 According to Embodiment 1, a battery swapping station 10 is provided, and the battery swapping station 10 includes: a battery swapping platform 11 and a charging room 12 connected to each other, a battery swapping device 13 , and a double-station palletizer 100 .

[0078]The battery swapping device 13 travels between the battery swapping platform 11 and the charging room 12 , and is used to remove and install batteries from vehicles on the battery swapping platform 11 .

[0079] The double-station palletizer includes a first push-out mechanism and a second push-out mechanism; the first push-out mechanism is used to take and place fully charged battery packs, and the second push-out mechanism is used to take and release exhausted battery packs; the first push-out mechanism and the second push-out mechanism The push-out mechanisms are controlled separately, and both are used to exchange batteries with the power exchange device 13 .

[0080] The power exchange s...

Embodiment 2

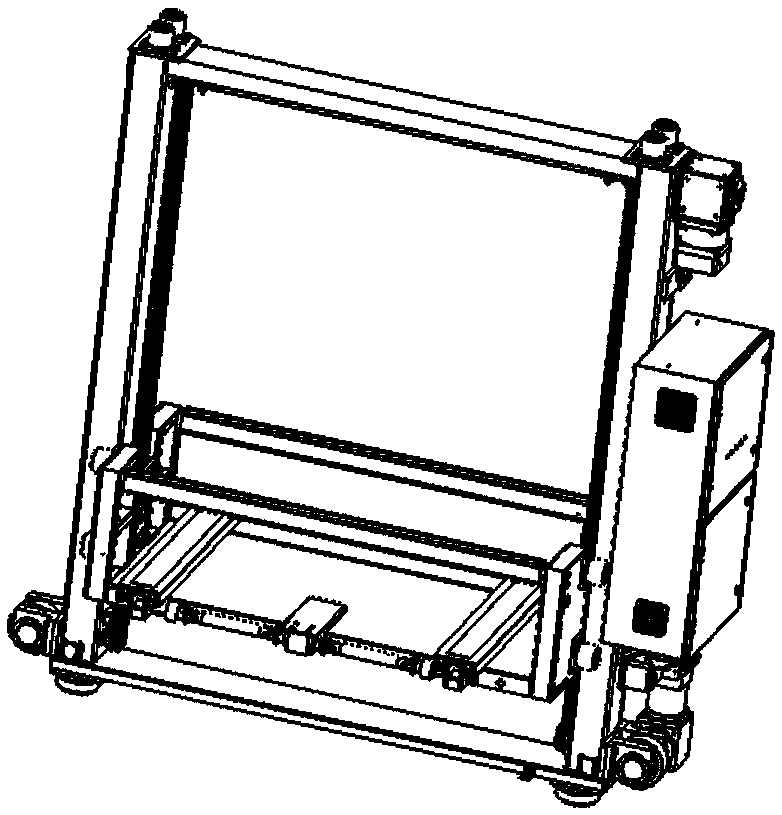

[0101] Figure 4 The double-station palletizer 200 of Embodiment 2 is shown. The double-station palletizer 200 includes: a first push-out mechanism 220 and a second push-out mechanism 230 .

[0102] The first push-out mechanism 220 is used to take and place the fully charged battery pack, and the second push-out mechanism 230 is used to take and put away the battery pack with a low charge. Of course, the functions of the two can also be exchanged.

[0103] The first push-out mechanism 220 and the second push-out mechanism 230 are controlled separately.

[0104] The first push-out mechanism 220 and the second push-out mechanism 230 are arranged side by side.

[0105] The structures of the first push-out mechanism 220 and the second push-out mechanism 230 in the second embodiment are the same as those of the first push-out mechanism 110 and the second push-out mechanism 120 in the first embodiment.

[0106] The double-station palletizer 200 also has two push-out mechanisms, ...

Embodiment 3

[0110] Such as Figure 5 As shown, Embodiment 3 provides a control method for a power exchange station, and the control method is used to control the power exchange station in Embodiment 1. The battery replacement method includes the following steps:

[0111] S1: After the control unit obtains the signal that the vehicle is parked in place, it sends the first battery replacement command to the battery replacement device, and sends the second battery replacement command to the double-station palletizer;

[0112] The double-station palletizer receives the second battery replacement command and controls the first push-out mechanism to take out the fully charged battery pack from the charging room (new warehouse) of the battery swap station, and moves to the battery swap station of the battery swap station to stand by.

[0113] When taking out the fully charged battery pack, the double-station palletizer moves in the charging room of the power station through the horizontal trave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com