Optical fiber mounting clamp suitable for flexible structure and using method thereof

A flexible structure and installation fixture technology, applied in the direction of optical fiber/cable installation, fiber mechanical structure, etc., can solve problems such as breakage, large deformation, excessive deformation of optical fiber, etc., to reduce stress and deformation, low cost, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

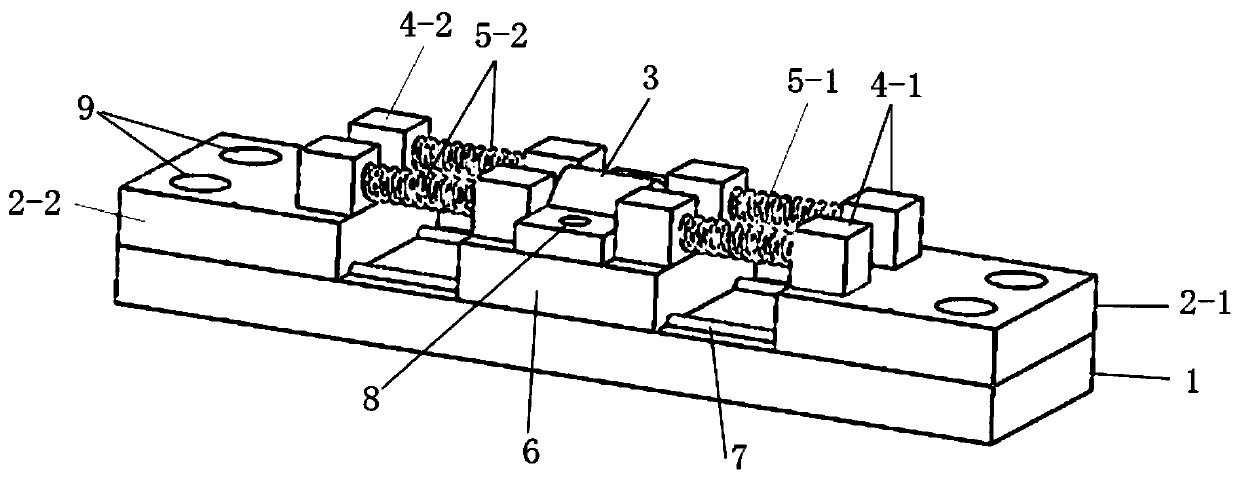

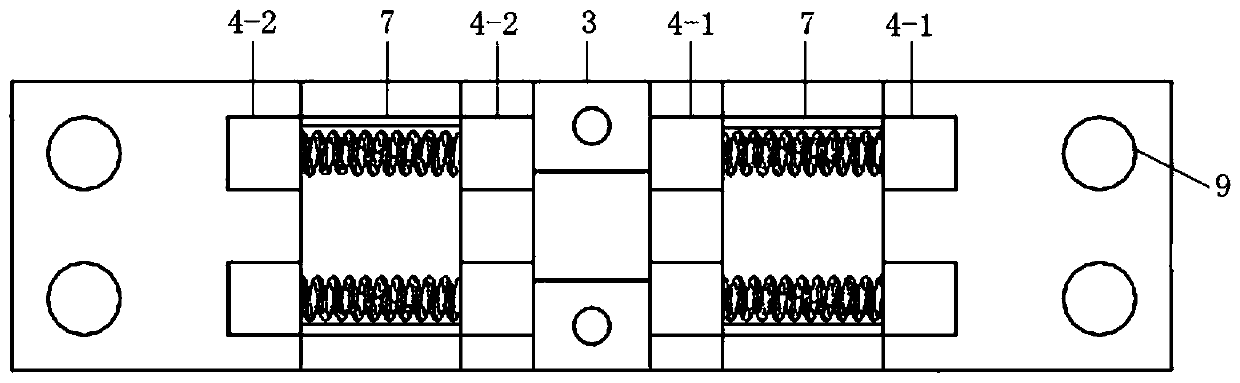

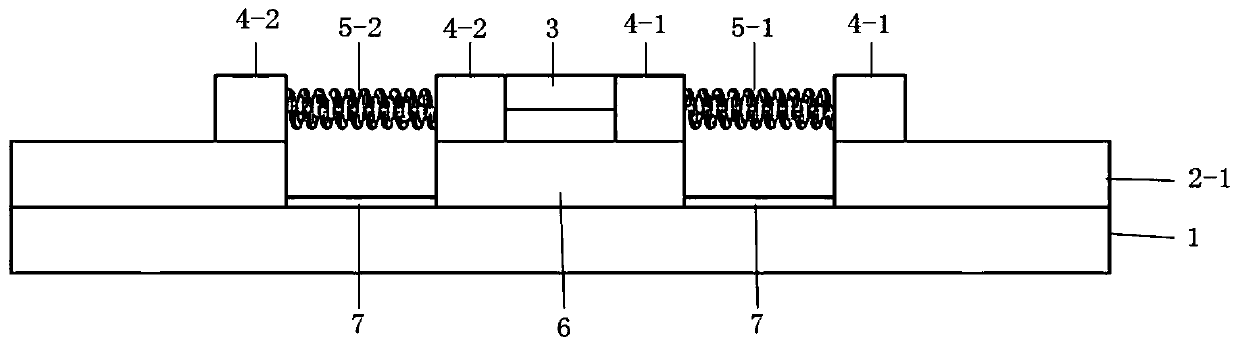

[0020] see Figure 1 ~ Figure 4 , an optical fiber installation fixture suitable for flexible structures, comprising a base 1, a front pressing piece 2-1 is provided at the front end of the base 1, and a rear pressing piece 2 is provided at the rear end of the base 1 -2.

[0021] Two sliding rails 7 parallel to each other and extending along the length direction of the base are fixedly connected between the front-end pressing piece 2-1 and the rear-end pressing piece 2-2, and a slider is installed on the sliding rail 7 6. The slider 6 is slidingly matched with the base 1 , and the fiber clamp 3 is fixedly installed on the slider 6 .

[0022] Two limit springs I5-1 symmetrically arranged at the front end of the slider 6 are arranged, and two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com