Self-discharging medicine stirring device

A stirring device and self-unloading technology, which is applied in the directions of mixer accessories, transportation and packaging, dissolution, etc., can solve the problems of low conveying efficiency, and achieve the effects of high conveying efficiency, simple structure, and avoidance of electronic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

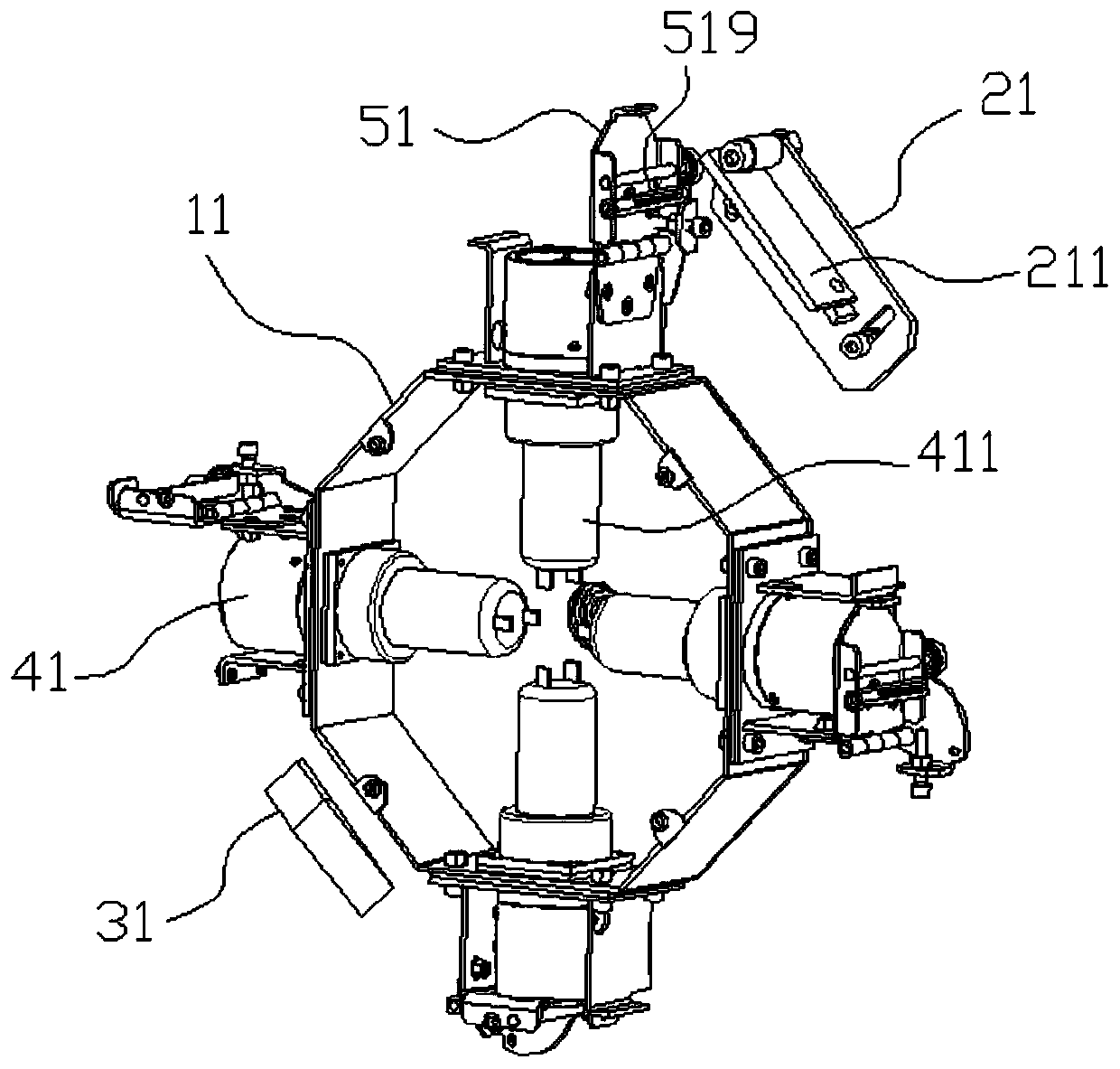

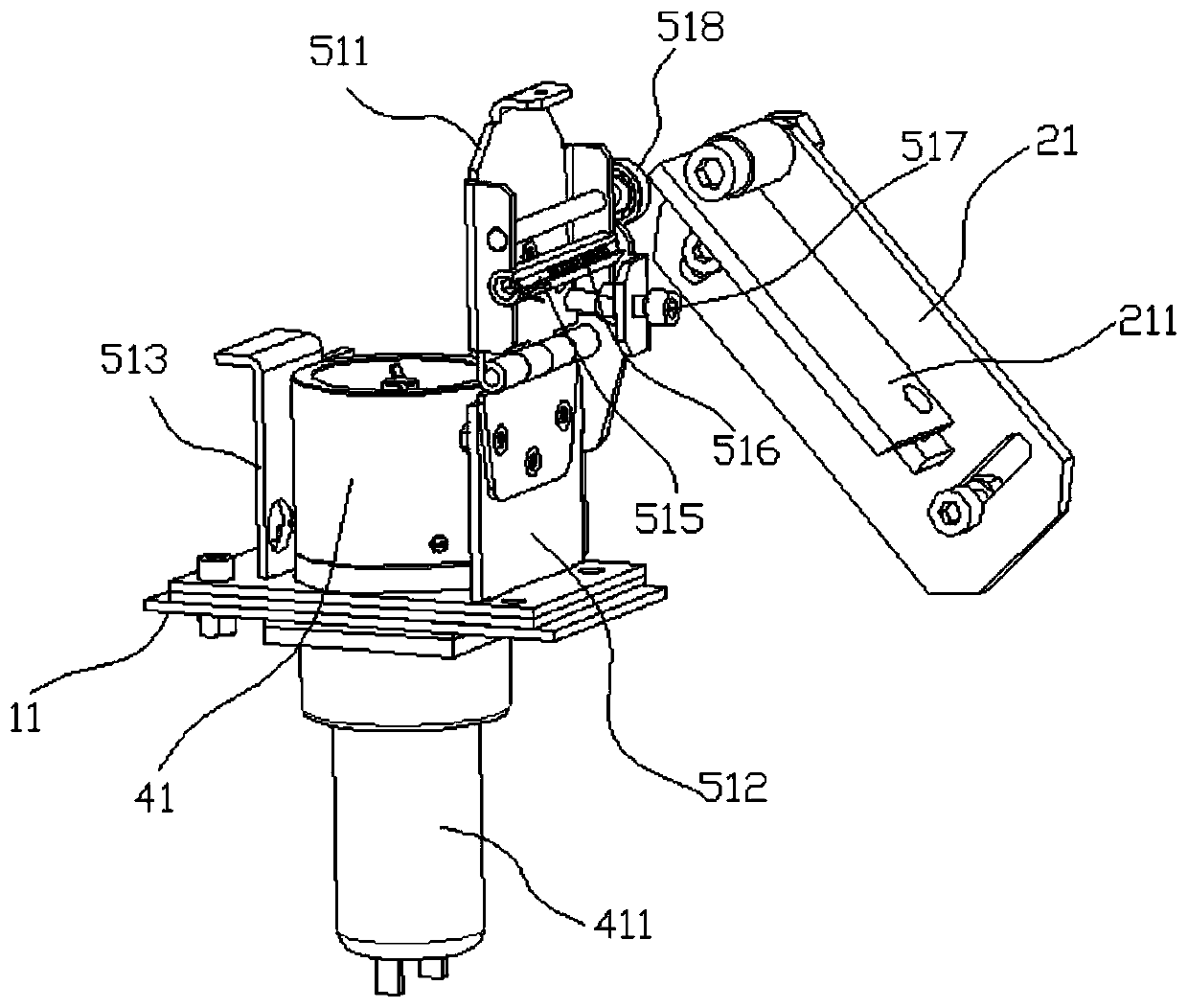

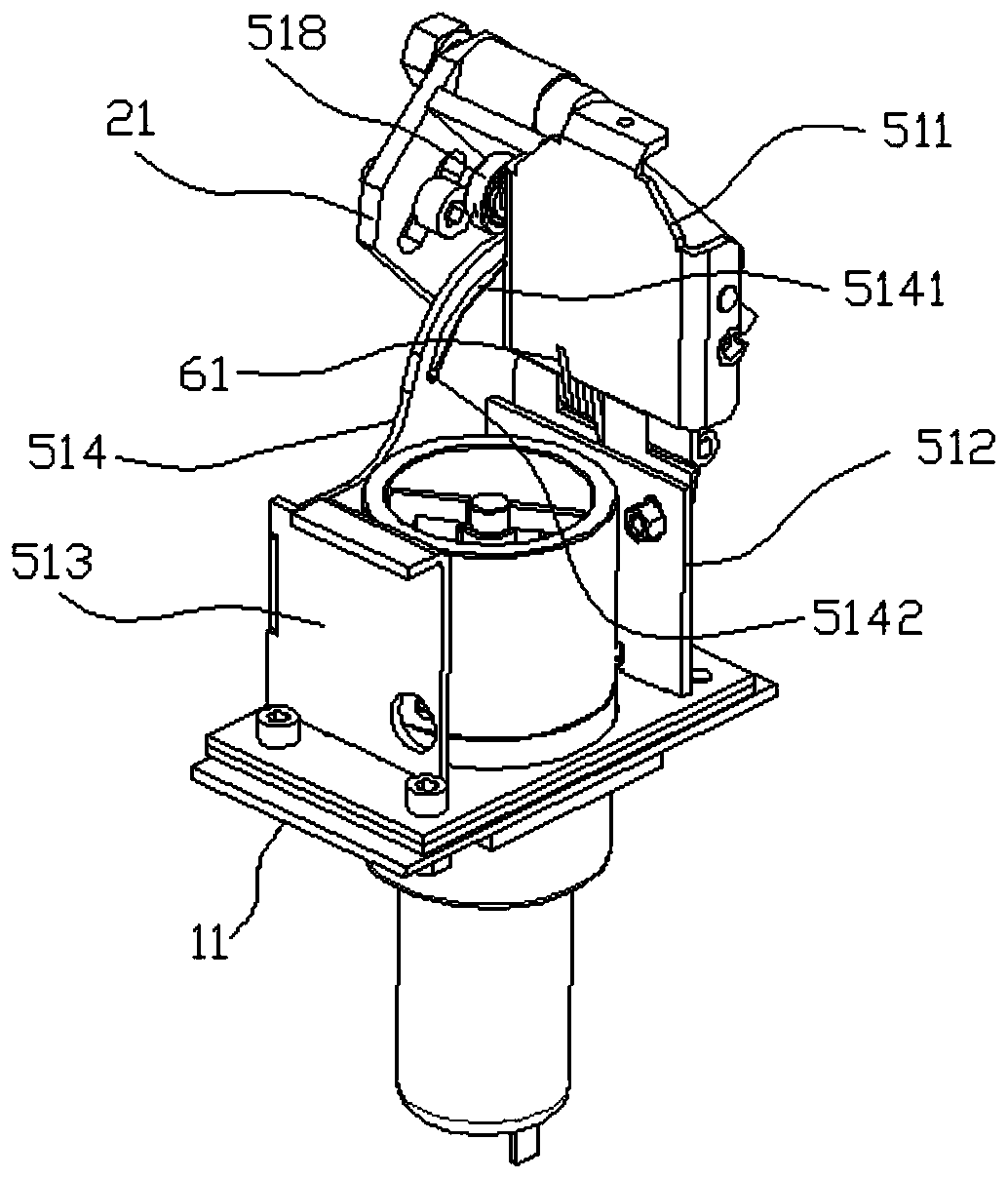

[0023] like Figure 1 to Figure 6 , a kind of self-unloading medicine stirring device of the present invention, comprises turret 11, driving plate 21, unloading plate 31, mixing barrel 41, sealing cover 51 and torsion spring 61, and turret 11 is regular octagonal structure, in turret Four outer sides of 11 are fixed with a mixing bucket 41, and the mixing bucket 41 rotates together with the turret 11, and a sealing cover 51 is provided on one side of each mixing bucket 41, and the torsion spring 61 is installed on the sealing cover 51, The elastic force of the torsion spring 61 stretches the sealing cover 51 and makes the upper port of the mixing bucket 41 open. The driving plate 21 and the discharge plate 31 are both arranged on the rotation path of the sealing cover 51 rotating with the turret 11 .

[0024] When the sealing cover 51 is in contact with the driving pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com