A digital temperature measurement system for mass concrete construction

A large-volume concrete and temperature-measuring point technology, applied in control/regulation systems, thermometers, heat measurement, etc., can solve the problems of temperature measurement errors, inconvenient operation, and cumbersome temperature sensor circuits, and achieve uniform layout, convenient operation, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

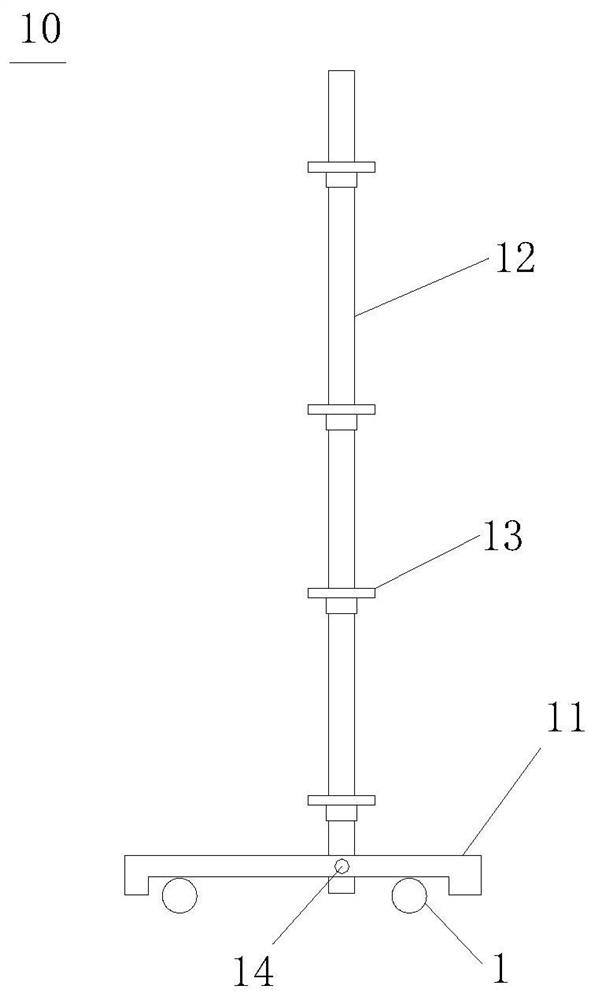

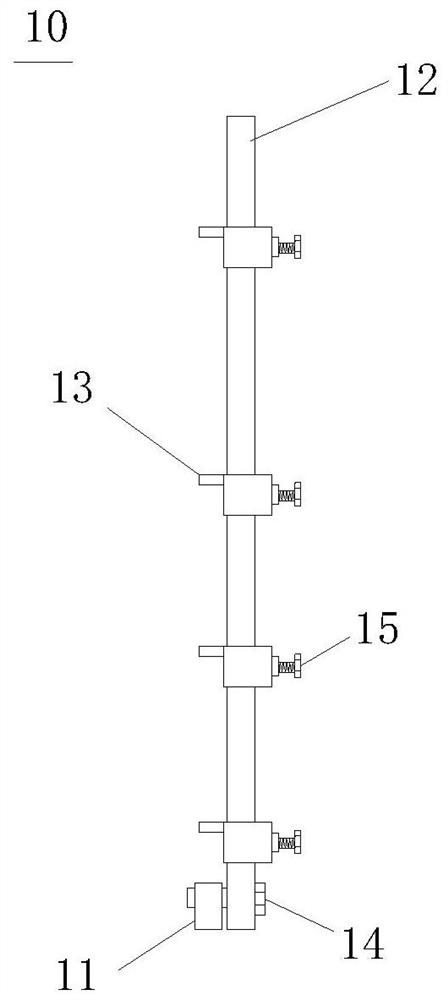

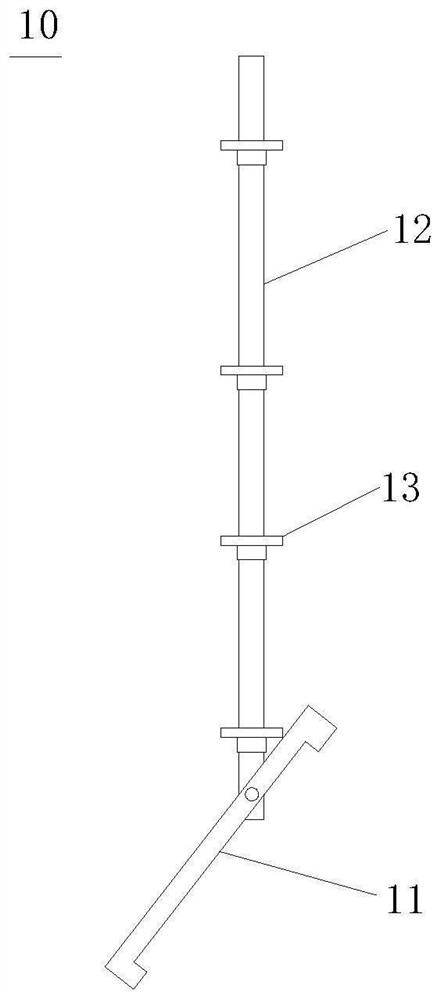

[0030] This embodiment provides a digital temperature measurement system for large-volume concrete construction. figure 1 to attach Figure 5 The temperature measurement method is further described. The temperature measurement system includes: a temperature measurement device bracket 10, several series temperature measurement devices, a data acquisition device and a server.

[0031] Several temperature measuring points are arranged inside the mass concrete, and a temperature measuring device bracket 10 is arranged at each temperature measuring point. Such as Figure 1 to Figure 3 As shown, the temperature measuring device bracket 10 includes a support base 11 and a vertical bar 12 arranged on the support base 11, the support base 11 is hinged to the bottom end of the vertical bar 12, and the hinge point is close to one end of the support base 11; the vertical bar 12 is provided with several short crossbars 13 for fixing the series temperature measuring device at intervals. ...

Embodiment 2

[0039] This embodiment provides a digital temperature measurement method for mass concrete construction. figure 1 To attach Figure 5 The temperature measurement method is further described. Described temperature measuring method comprises the steps:

[0040] The first step is to fix the serial temperature measuring device on the temperature measuring device bracket. Such as Figure 1 to Figure 3 As shown, the temperature measuring device bracket 10 includes a support base 11 and a vertical bar 12 arranged on the support base 11, the support base 11 is hinged to the bottom end of the vertical bar 12, and the hinge point is close to one end of the support base 11; the vertical bar 12 is provided with several short crossbars 13 for fixing the series temperature measuring device at intervals.

[0041] For the specific structure of the temperature measuring device bracket and the series temperature measuring device, please refer to Embodiment 1, which will not be repeated here...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com