Chilli sauce processing system and chilli sauce processing method

A processing system and chili sauce technology, applied in cocoa, grain processing, food science, etc., can solve the problem of not being able to add different processing raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

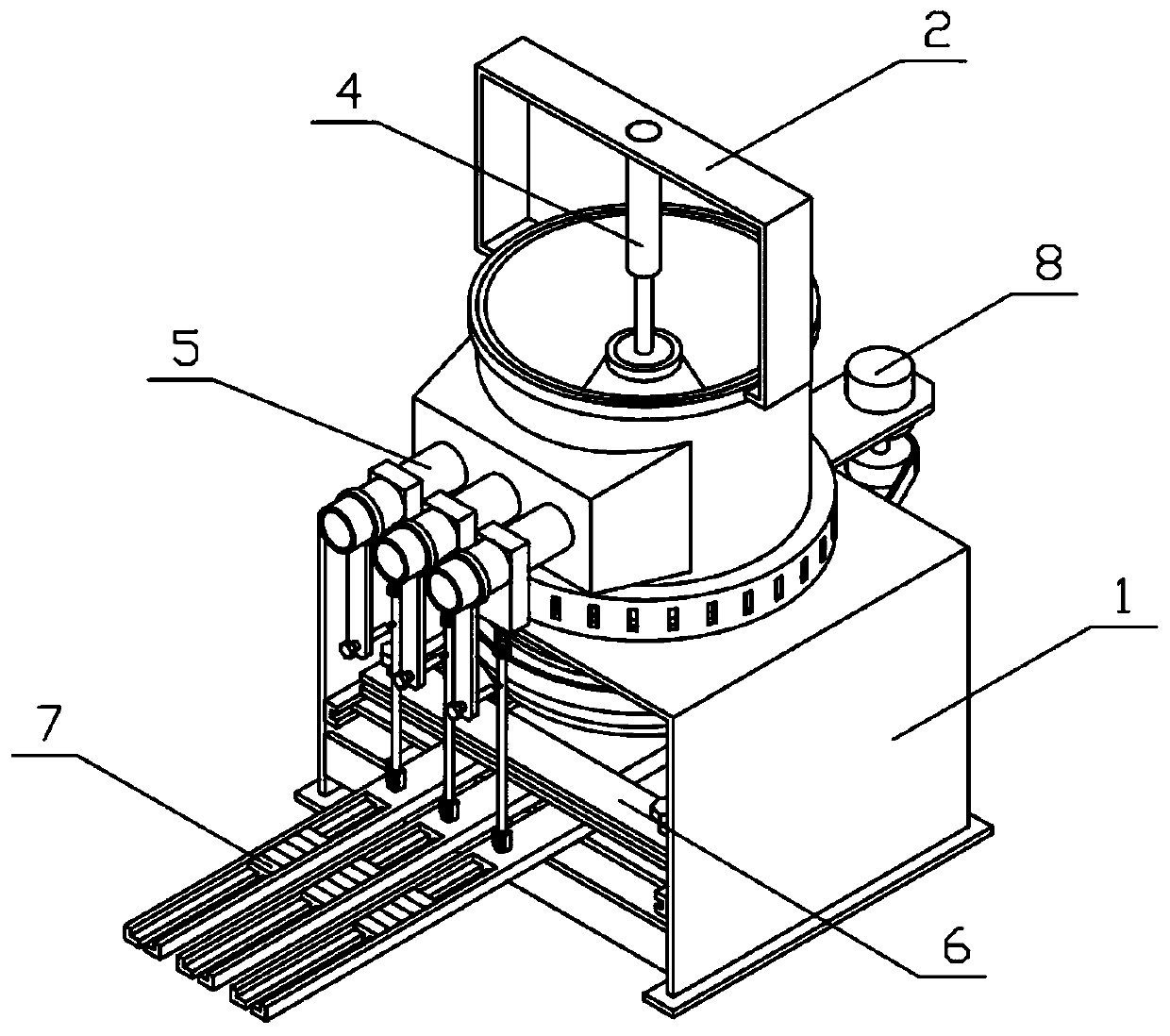

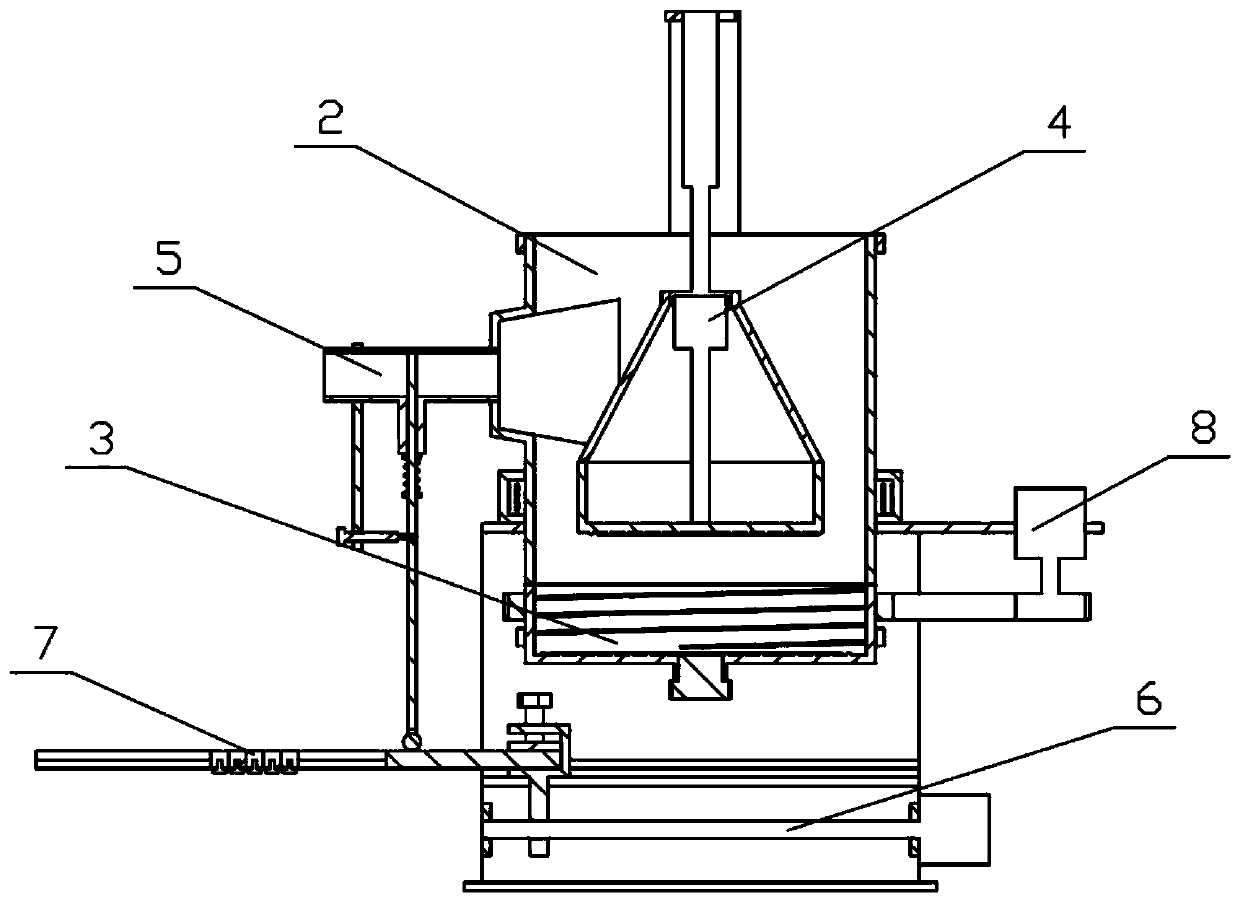

[0039] Combine below Figure 1-12Describe this embodiment, a kind of chili sauce processing system, comprises device support 1, stirring support 2, stirring mechanism I3, stirring mechanism II4, feeding mechanism 5, pulling mechanism 6, control module 7 and stirring motor II8, described device support 1 is fixedly connected with stirring support 2, the lower end of stirring support 2 is rotatably connected with stirring mechanism Ⅰ3, the upper end of stirring support 2 is fixedly connected with stirring mechanism Ⅱ4, and the device support 1 is fixedly connected with stirring motor Ⅱ8, stirring motor Ⅱ8 and stirring mechanism Ⅰ3 Transmission connection, the stirring support 2 is fixedly connected with multiple feeding mechanisms 5, and the multiple feeding mechanisms 5 are all connected to the stirring support 2, and the multiple feeding mechanisms 5 are respectively connected to different raw material pipelines, and the device support 1 is connected with a pull Mechanism 6, m...

specific Embodiment approach 2

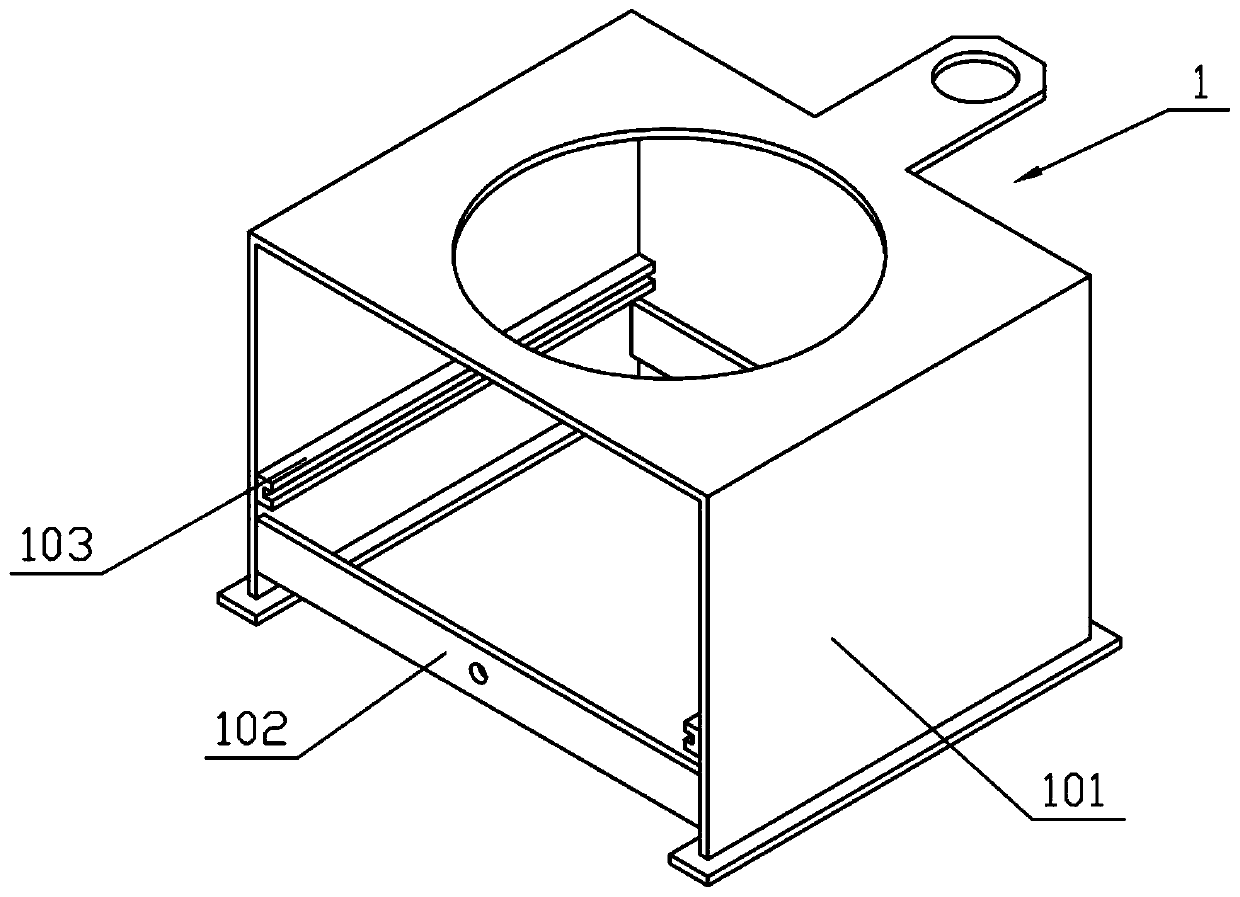

[0041] Combine below Figure 1-12 Illustrate this embodiment, and this embodiment will further describe Embodiment 1. The device bracket 1 includes a support bracket 101, a connecting plate 102 and a slide rail 103, and the front and rear sides of the supporting bracket 101 are fixedly connected with a connecting plate 102. Slide rails 103 are fixedly connected to the left and right sides of 101 , and the stirring motor II 8 is fixedly connected to the support bracket 101 .

specific Embodiment approach 3

[0043] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the second embodiment, the stirring support 2 includes a mixing drum 201, a connecting frame 202, a trapezoidal mounting surface 203 and a heating mechanism 204, and the upper end of the mixing drum 201 is fixedly connected with a connecting frame 202 , the mixing drum 201 is provided with a trapezoidal mounting surface 203 , the heating mechanism 204 is provided on the mixing drum 201 , and the mixing drum 201 is fixedly connected to the support bracket 101 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com