Production process for starching-free quick-frozen fillets

A production process and fish fillet technology, which is applied in the direction of slicing fish, preserving meat/fish by freezing/cooling, and cutting fish into parts, etc., which can solve the problem of slurry penetrating into fish meat, affecting the taste and quality of fish fillets, Problems such as long production cycle of frozen fish fillets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

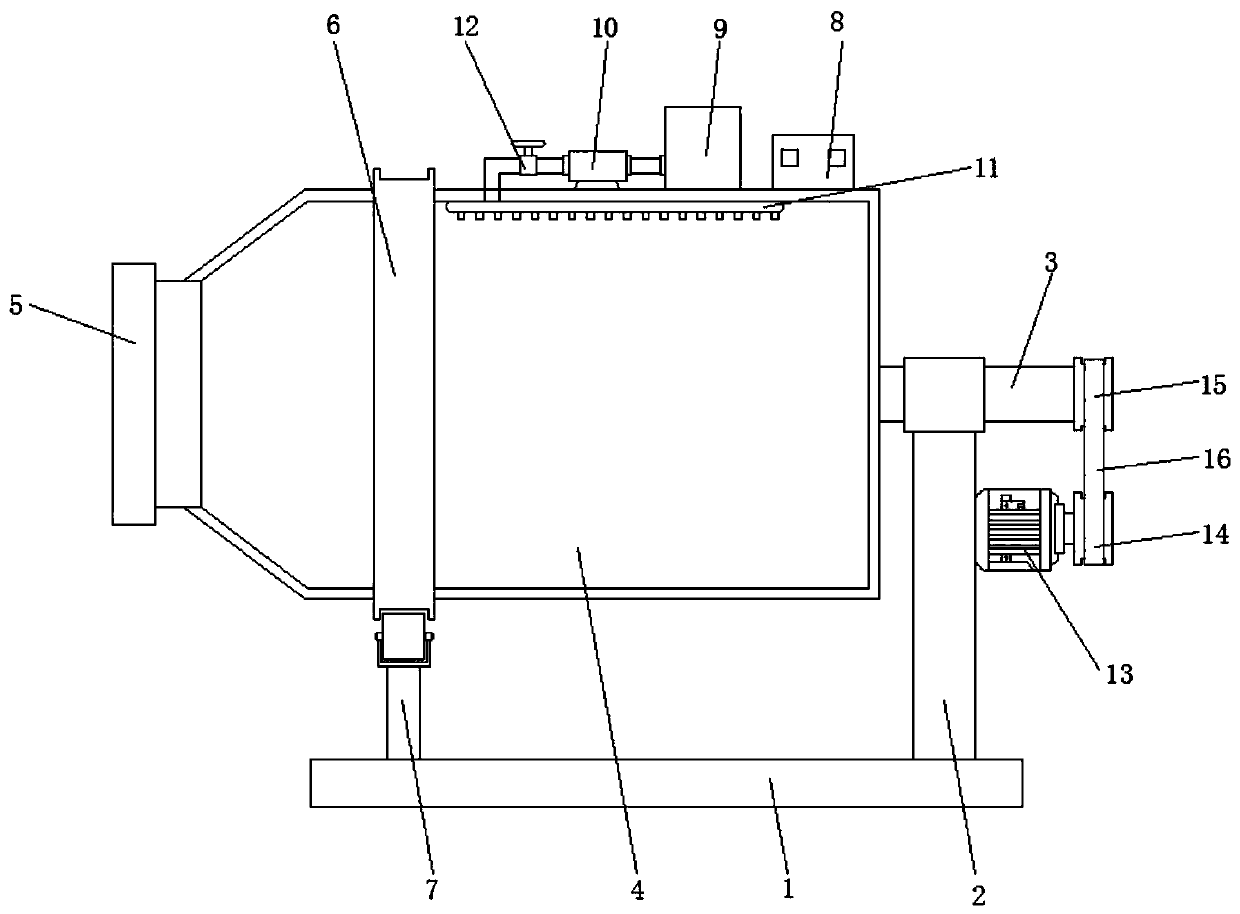

Image

Examples

Embodiment 1

[0033] The production process of pulp-free quick-frozen fish fillets includes the following steps:

[0034] Step 1: Take the fresh fish and put them in the pool to stand still, then manually remove the scales and heads, and then clean the processed fish, and let the live fish stand in the pool overnight;

[0035] Step 2: Remove the middle bone of the cleaned fish, trim the fish meat, and cut into large pieces of fish for use;

[0036] Step 3. Place the cut large pieces of fish fillets in clean water for bleaching, and then add the large pieces of fish fillets to the bubble cleaner to clean the surface impurities. The rinsing time for the large pieces of fish fillets is 30 -40 minutes, the temperature of flushing with water is set to 10℃-15℃;

[0037] Step 4. Remove the cleaned large pieces of fish fillets to filter out the surface water, and put them in a container containing deodorant liquid, soaking time is 30-40 minutes;

[0038] Step 5: Take out the fish fillet after removing the f...

Embodiment 2

[0044] The production process of pulp-free quick-frozen fish fillets includes the following steps:

[0045] Step 1: Take the fresh fish and put them in the pool to stand still, then manually remove the scales and heads, and then clean the processed fish, and let the live fish stand in the pool overnight;

[0046] Step 2: Remove the middle bone of the cleaned fish, trim the fish meat, and cut into large pieces of fish for use;

[0047] Step 3. Place the cut large pieces of fish fillets in clean water for bleaching, and then add the large pieces of fish fillets to the bubble cleaner to clean the surface impurities. The rinsing time for the large pieces of fish fillets is 30 -40 minutes, the temperature of flushing with clean water is set to 10℃-15℃;

[0048] Step 4. Remove the cleaned large pieces of fish fillets to filter out the surface water, and put them in a container containing deodorant liquid, soaking time is 30-40 minutes;

[0049] Step 5: Take out the fish fillets after removin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com