Portable swing angle testing device for automobile windscreen wiper

A test device and a portable technology, applied in the field of portable swing angle test devices, can solve problems such as the inconvenience of developing and loading wiper products, the inability to test R&D products in time, and the inability to test the wiper swing angle, so as to ensure the progress of research and development, Simple structure and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

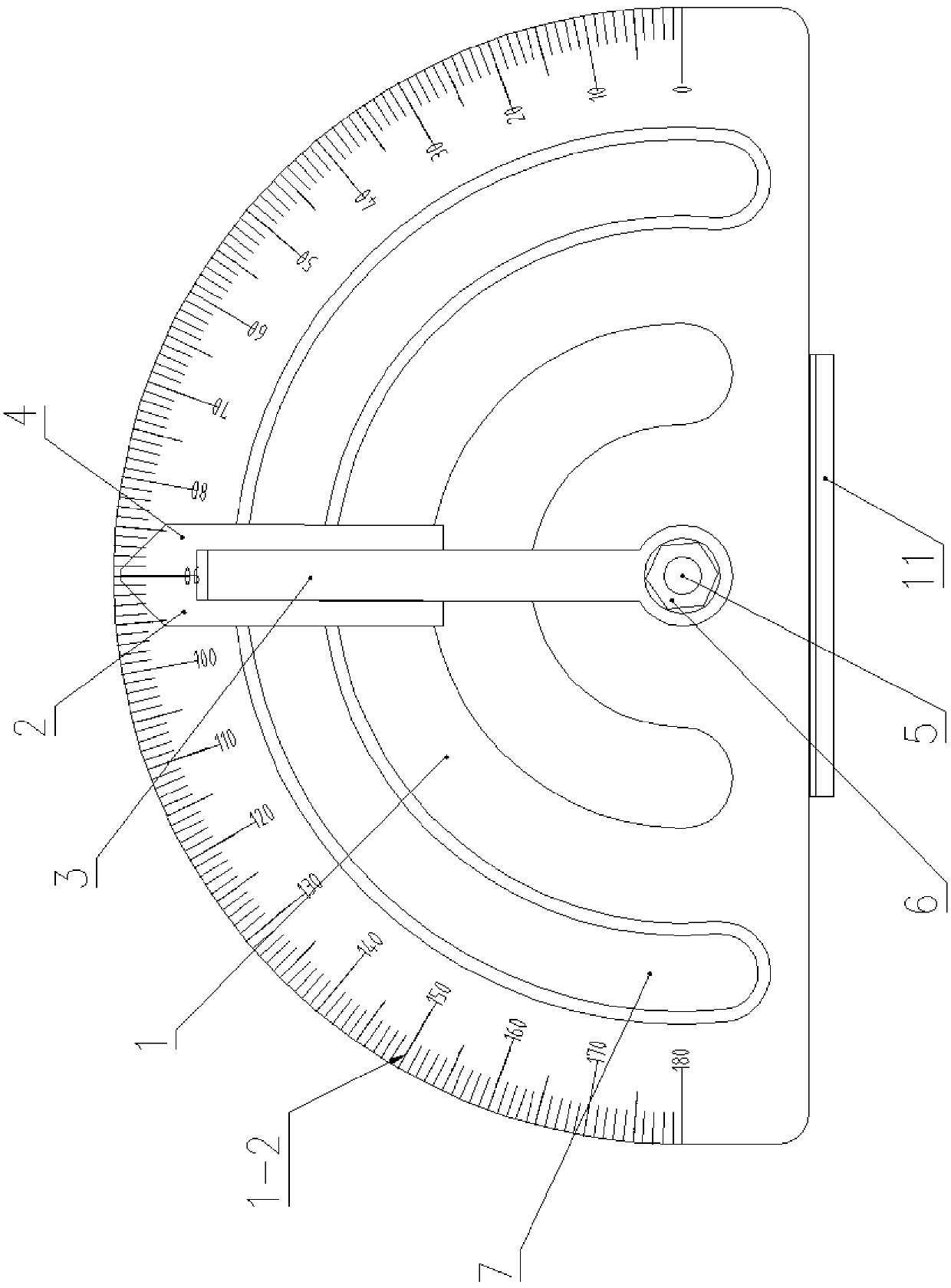

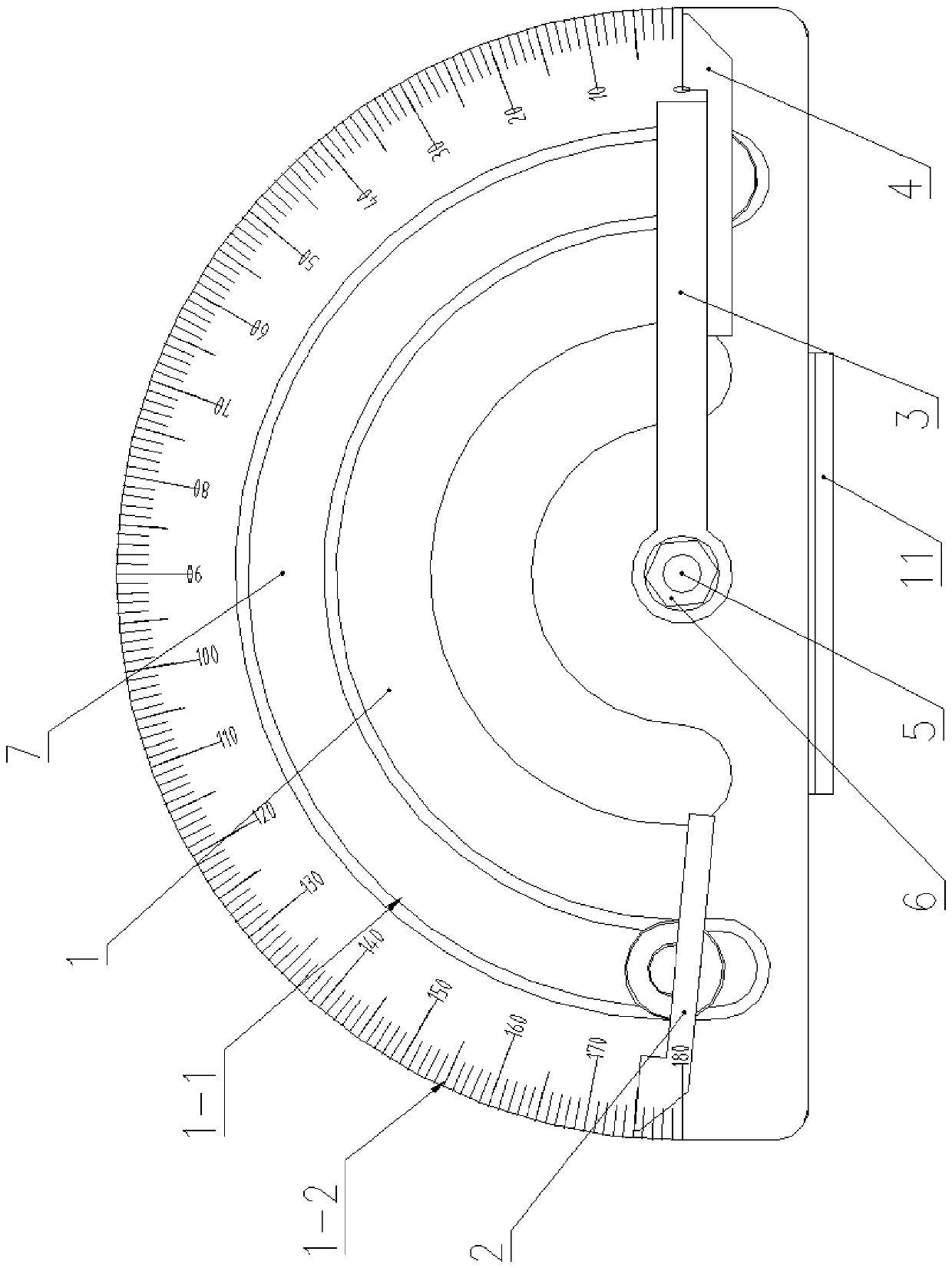

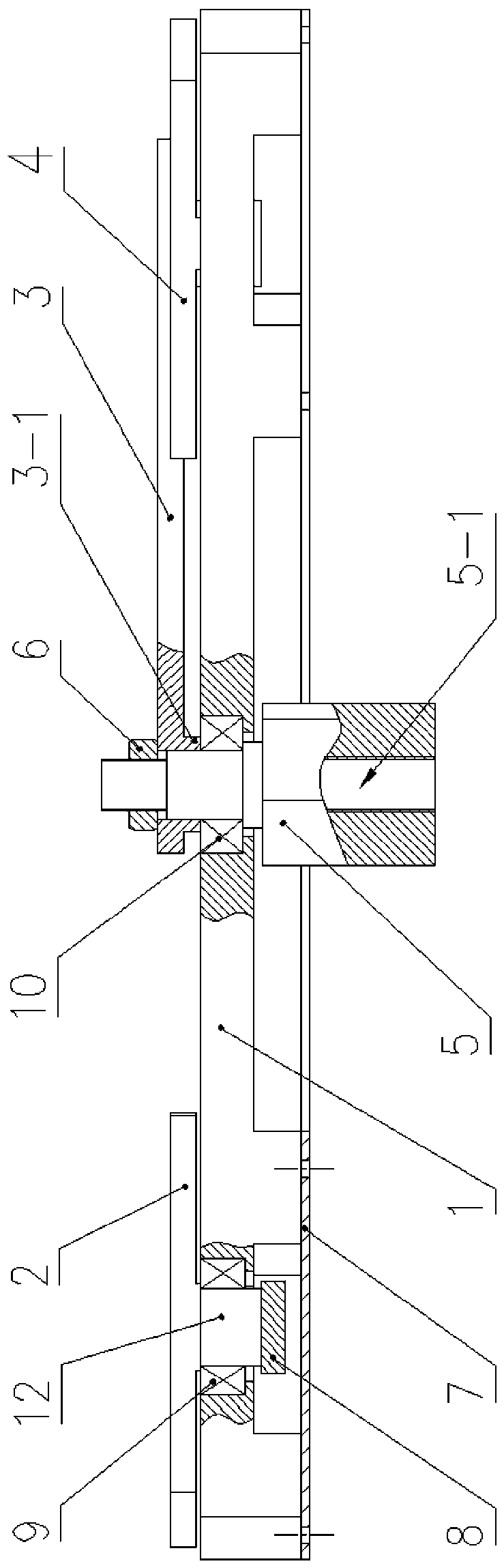

[0033] see Figure 1 to Figure 8, a portable swing angle testing device for an automobile wiper, comprising a dial 1, and a fixing base 11 for fixing the dial 1 is arranged at the lower end of the dial 1 . The upper end of the fixed base 11 is provided with a detent 11-1 for preventing the dial 1 from rotating. The detent 11-1 is located at the upper end of the side wall of the fixed base 11 and extends upward. The detent 11-1 is against the scale. The linear side wall of the disc 1 forms a limit. The anti-rotation part 11-1 restricts the rotation of the dial 1, which can improve the accuracy of test results. The dial 1 is provided with a guide groove 1-1 in the shape of a superior arc, and along the extending direction of the guide groove 1-1, an angle marking line 1-2 is provided, and the angle marking line 1-2 is 0-180 degrees. The side wall of the dial 1 located outside the guide groove 1-1 is in the shape of a semicircle. The dial 1 is located at the center of the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com