Method for adjusting oil nozzle through liquid drainage test after fracturing of normal-pressure shale gas horizontal well

An adjustment method, a shale gas technology, is applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc. It can solve problems such as unclear timing of choke adjustment, prolonged adjustment, and increased reservoir liquid phase permeability, etc., to achieve Avoid the rapid increase of liquid phase permeability and reduce the effect of operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

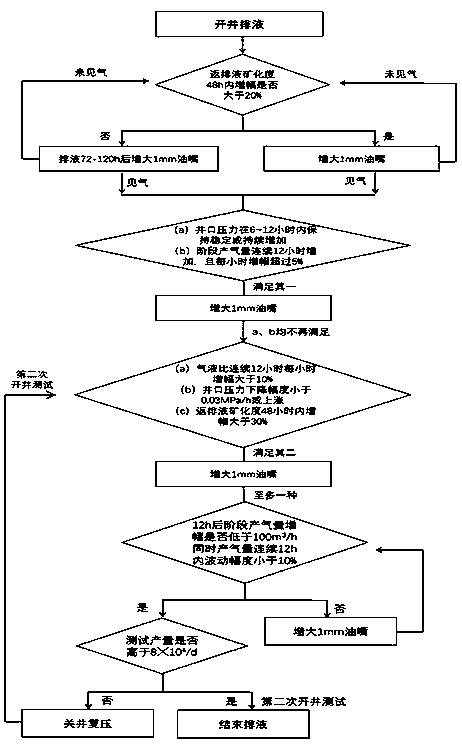

[0032] As a preferred embodiment of the present invention, it discloses a method for adjusting the liquid discharge test nozzle after the fracturing of an atmospheric shale gas horizontal well, the steps of which are as follows:

[0033] (1) After the fracturing of normal pressure shale gas horizontal wells is completed, the wells are opened and drained, and the first stage is the stage of pure liquid phase flow. At this stage, only the liquid is discharged. Observe the salinity index of the flowback liquid. If the index remains relatively stable and the increase rate is less than 20% within 48 hours, it can be gradually increased in units of 1 mm after the liquid is discharged for 72-120 hours in a nozzle system; If the salinity increase exceeds 20% within 48 hours, immediately increase the 1mm nozzle; carry out the above procedures until the gas is seen;

[0034] (2) The initial stage of gas seepage refers to the stage when gas is discharged but the liquid discharge volume d...

Embodiment 2

[0037] Embodiment 2: Implementation example

[0038]Well A is a shale gas horizontal well at the southern edge of the Sichuan Basin. The target layer is the shale of the Longmaxi Formation. The vertical depth of the horizontal section is 2000-2050m, and the formation pressure coefficient is 1.2. It is a normal pressure shale gas well. The well has undergone fracturing in 20 stages.

[0039] Shut down the well for 230 hours after fracturing, and use a 3mm choke nozzle to open the well and drain the fluid for testing. The specific steps are as follows:

[0040] (1) The opening pressure is 12.5MPa, the pure liquid phase flow stage, the chloride content of the flowback liquid is 1791mg / L, and after 50h of liquid discharge, the chlorine content is 2349mg / L, no gas is seen, and it increases to a 4mm nozzle;

[0041] (2) The total liquid discharge time is 127 hours, the pure liquid phase flow stage, the chlorine root content is 5277mg / L, no gas is seen, and the nozzle is increased t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com