Recoverable large-resistance high-pressure drill hole sealing device and using method thereof

A sealing device and high-pressure sealing technology, used in sealing/sealing, earth-moving drilling, and fluid extraction, etc., can solve the problems of capsule fatigue wear, reduce service life, increase use cost, etc., to prevent leakage, improve safety, Avoid the effect of blocking failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described (hereinafter referred to as figure 1 The direction to the right of the front is described as the front).

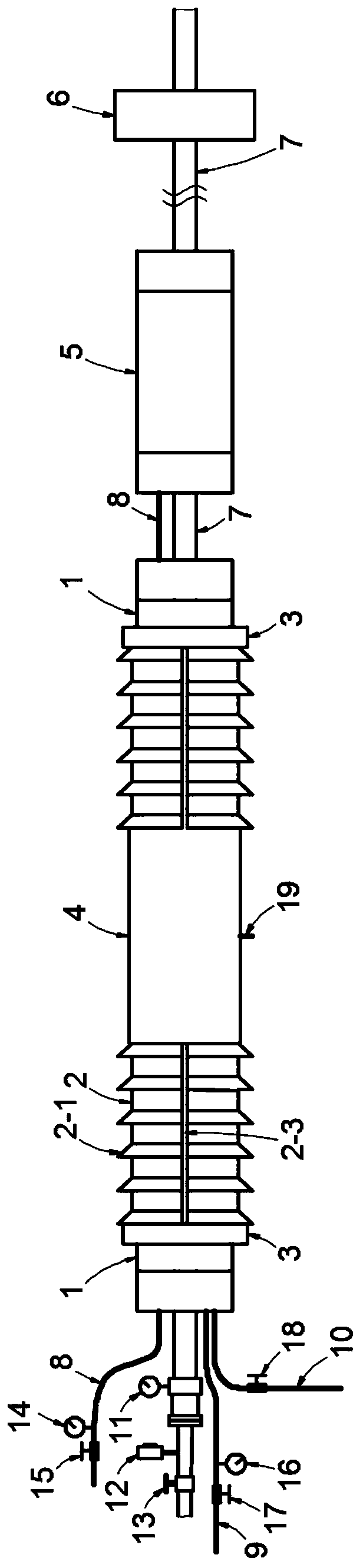

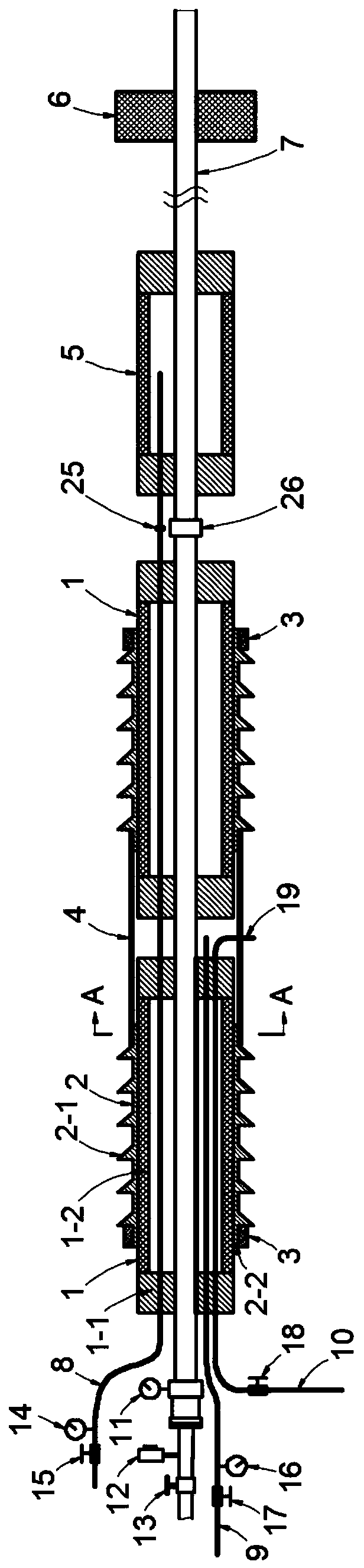

[0031] Such as figure 1 , figure 2 As shown, the recoverable large-resistance high-pressure drilling sealing device includes a sealing capsule part and a sealing and high-pressure injection control part.

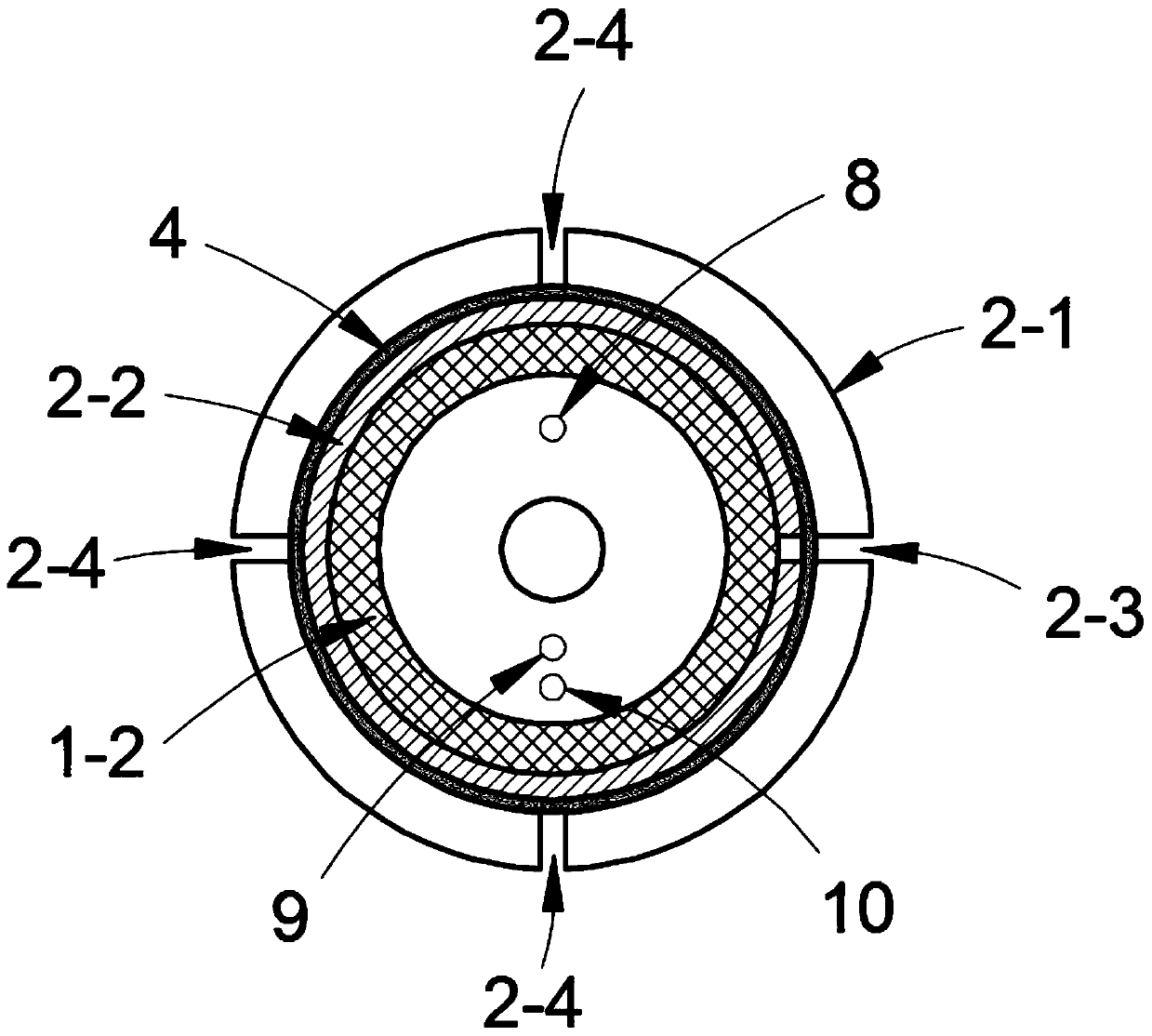

[0032] The sealed capsule part includes a high-pressure capsule assembly 1, and the high-pressure capsule assembly 1 includes a front capsule and a rear capsule coaxially arranged front and rear. The structure of the capsule body 1-2 between the sealing plates 1-1, the two sealing plates 1-1 and the capsule body 1-2 jointly form a closed cavity structure, and the capsule bodies 1-2 of the front capsule and the rear capsule are both The resistance-increasing part 2 with a sleeve structure is sleeved and installed, and the outer surface of the resistance-increasing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com