Modular wall convenient to assemble and disassemble

A modular and wall technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems of low structural strength, poor wall stability, and troublesome disassembly and assembly of modular walls, so as to overcome the inconvenience of installation and disassembly and improve the firmness The effect of improving stability and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

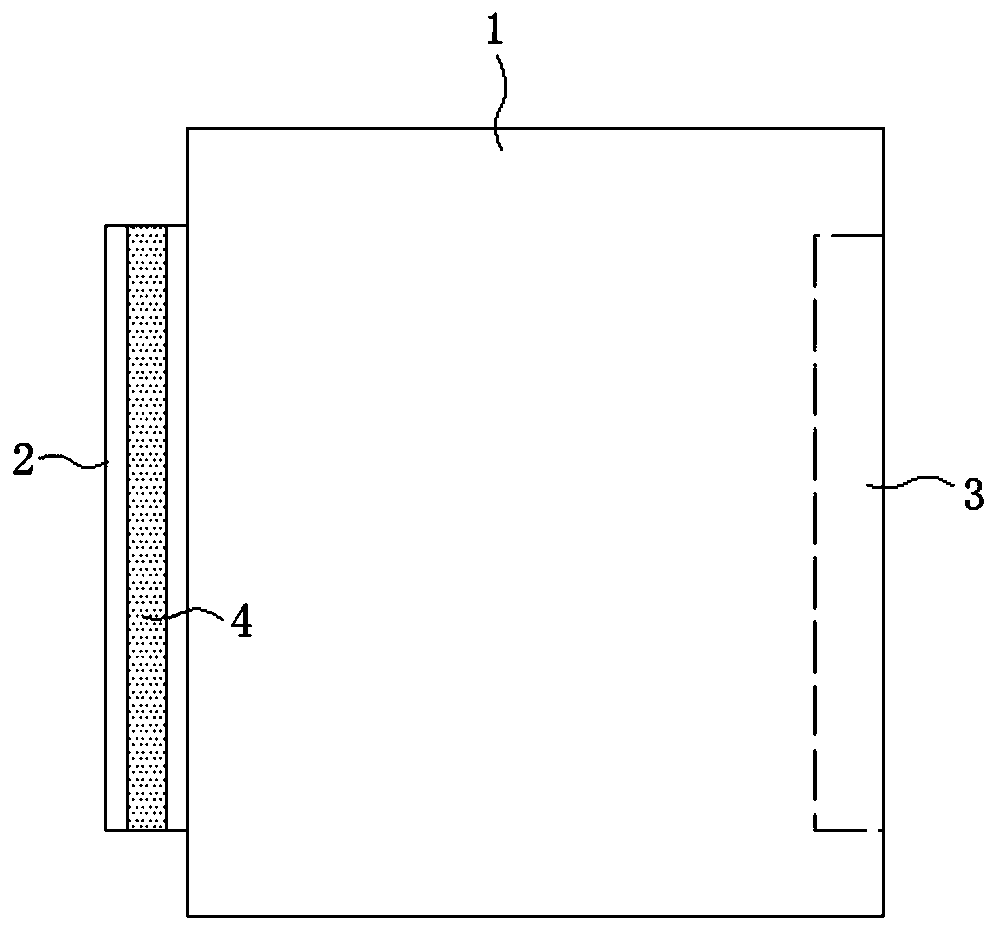

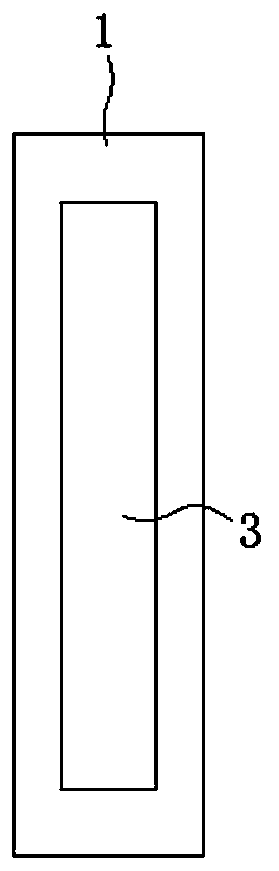

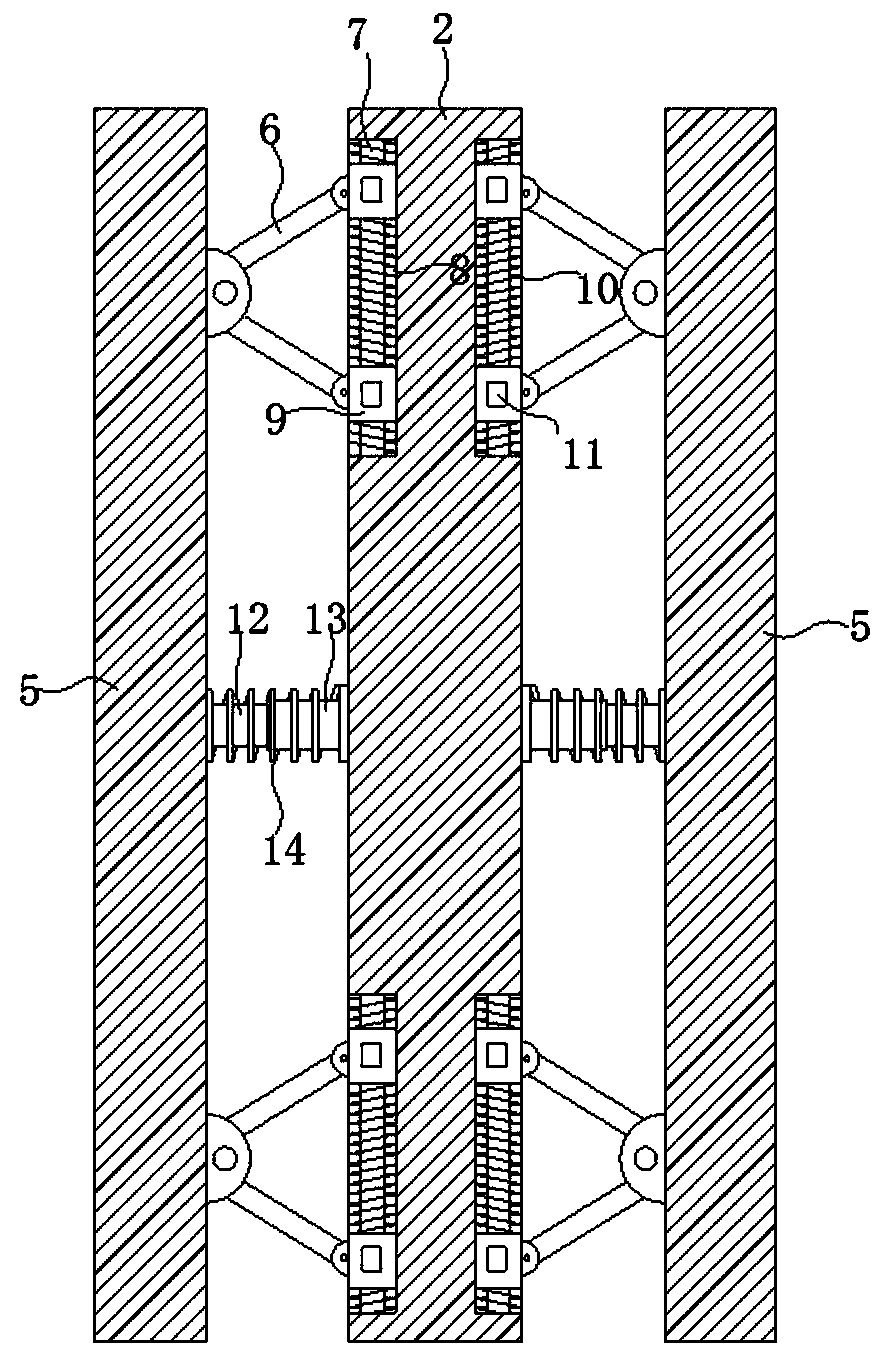

[0031] combine Figure 1-Figure 3 , a modular wall that is easy to install and disassemble in this embodiment includes a wall body 1, such as figure 1 , figure 2 As shown, one end of the wall main body 1 is provided with a slot 3, and the other end is correspondingly provided with an insert block 2, the main surface of the insert block 2 is slidably connected with the back plate 5 through a sliding connection mechanism, and the insert An elastic compression element 14 is connected between the block 2 and the abutment plate 5, through the cooperation of the sliding connection structure between the insert block 2 and the slot 3 and the setting of the elastic compression element, multiple wall bodies can be quickly installed and disassembled. Specifically, the height dimension of the slot 3 is the same as that of the insert block 2, and is located at the same level, and the width dimension of the slot 3 is greater than the width dimension of the insert block 2. Through the abov...

Embodiment 2

[0034] A kind of modular wall body that is easy to install and dismantle in this embodiment, its structure is basically the same as embodiment 1, and its difference mainly lies in: combining image 3In this embodiment, the sliding connection mechanism includes a hollow tube 13 with one end fixed on the insert block 2 and a connecting rod 12 with one end fixed on the counter plate 5, and the other end of the connecting rod 12 can be slidably sleeved in the hollow tube 13 , the elastic compression element 14 adopts a compression spring, and it is sleeved on the sliding connection mechanism (hollow tube 13 and connecting rod 12). In this embodiment, a compression spring is also sleeved on the slide bar 7 . When the wall panel main body 1 is subjected to external force, the wall main body 1 transmits the collision force to the insert block 2, and the insert block 2 oscillates back and forth, so that the abutment plate 5 is carried out through the slider, the hinge rod, the hollow ...

Embodiment 3

[0037] A modular wall body that is easy to install and disassemble in this embodiment, its structure is basically the same as that of Embodiment 2, the main difference is that the sliding connection mechanism of this embodiment adopts a slider-sliding rail mechanism (figure omitted), wherein the slider It is fixedly installed on the backing plate 5 and the inserting block 2 respectively with the slide rail, and the slide rail is processed with a chute for sliding cooperation with the slide block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com