Low-dielectric high-strength flexible transparent conductive film for folding screens

A transparent conductive film, low dielectric technology, applied in the direction of cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, conductors, etc., can solve the problem that the service life or bending life cannot meet the requirements, and it is difficult to conduct layers Good adhesion to substrates, low dielectric properties of transparent conductive films, etc., to achieve the effects of conductivity and transparency, good adhesion and reliability, and increase cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Synthesis of Naphthalene Cyclic Polyethylene Glycol Acrylate

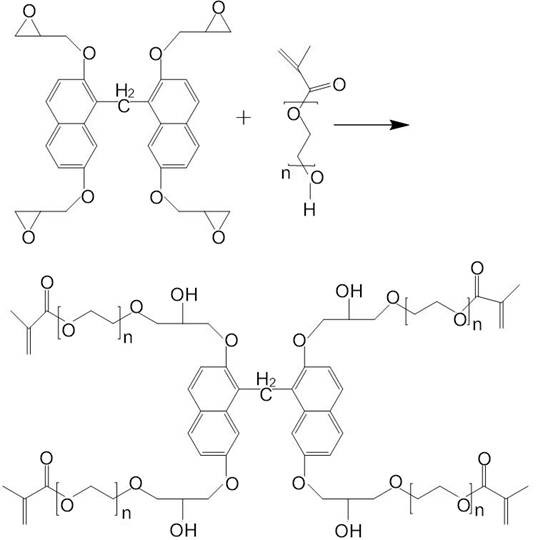

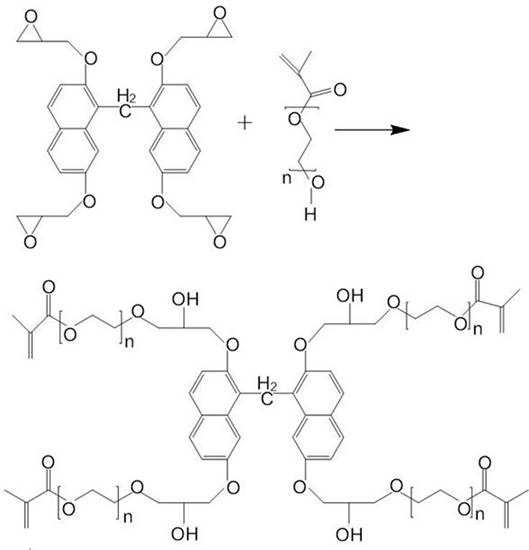

[0031] In solvent A, add naphthalene ring-type tetrafunctional epoxy resin (HP-4700 from DIC Japan), polyethylene glycol methacrylate and basic catalyst, react at 80°C for 1 hour, and then purify To obtain naphthalene ring-type polyethylene glycol acrylate, the mass ratio of naphthalene ring-type tetrafunctional epoxy resin, polyethylene glycol methacrylate and basic catalyst is 1:1:0.01, and the chemical reaction equation is shown in the figure below :

[0032]

[0033] where n is 5;

[0034] The basic catalyst is triethylamine, and the solvent A is formamide.

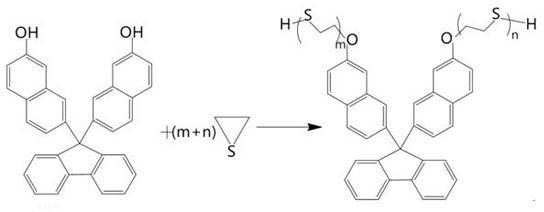

[0035] (2) Synthesis of naphthyl fluorene polythiol

[0036] Add 9,9-Bis(6-hydroxy-2-naphthyl)fluorene (CAS number: 934557-66-1), ethylene sulfide, basic catalyst and solvent A together, the reaction temperature is 60°C, and the reaction Naphthylfluorene polythiol can be obtained after 2 hours, wherein the mass ratio of 9,9-Bis(6-hydroxy-2-...

Embodiment 2

[0044] (1) Synthesis of Naphthalene Cyclic Polyethylene Glycol Acrylate

[0045] In solvent A, add naphthalene ring-type tetrafunctional epoxy resin (HP-4700 from DIC Corporation of Japan), polyethylene glycol methacrylate and basic catalyst, react at a temperature of 120°C for 4 hours, and then purify To obtain naphthalene ring-type polyethylene glycol acrylate, the mass ratio of naphthalene ring-type tetrafunctional epoxy resin, polyethylene glycol methacrylate and basic catalyst is 1:5:0.04, and its synthesis route is shown in the figure below:

[0046]

[0047] where n is 15;

[0048] The basic catalyst is potassium carbonate, and the solvent A is tetramethylethylenediamine.

[0049] (2) Synthesis of naphthyl fluorene polythiol

[0050] Add 9,9-Bis(6-hydroxy-2-naphthyl)fluorene (CAS number: 934557-66-1), ethylene sulfide, basic catalyst and solvent A together, the reaction temperature is 120°C, and the reaction Naphthylfluorene polythiol can be obtained after 5 hours...

Embodiment 3

[0058] (1) Synthesis of Naphthalene Cyclic Polyethylene Glycol Acrylate

[0059] In solvent A, add naphthalene ring-type tetrafunctional epoxy resin (HP-4700 from DIC Japan), polyethylene glycol methacrylate and basic catalyst, react at 100°C for 3 hours, and then purify Obtain naphthalene ring-type polyethylene glycol acrylate, wherein the mass ratio of naphthalene ring-type tetrafunctional epoxy resin, polyethylene glycol methacrylate and basic catalyst is 1:3:0.03, and its synthesis route is shown in the figure below :

[0060]

[0061] where n is 10;

[0062] The basic catalyst is sodium carbonate, and the solvent A is dioxane.

[0063] (2) Synthesis of naphthyl fluorene polythiol

[0064] Add 9,9-Bis(6-hydroxy-2-naphthyl)fluorene (CAS number: 934557-66-1), ethylene sulfide, basic catalyst and solvent A together, the reaction temperature is 100°C, and the reaction After 3 hours, naphthyl fluorene polythiol can be obtained, in which the mass ratio of 9,9-Bis(6-hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com