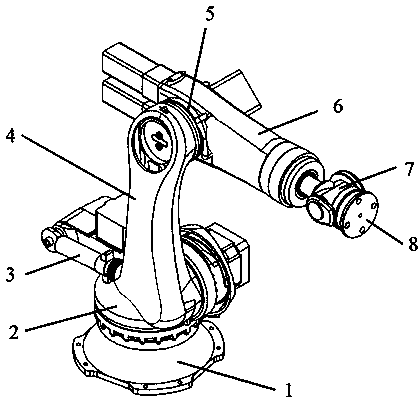

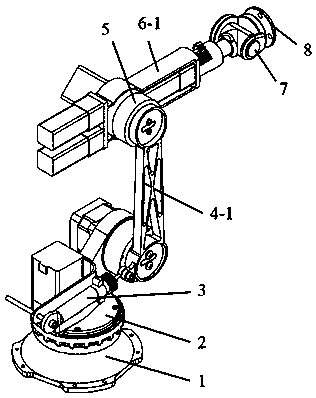

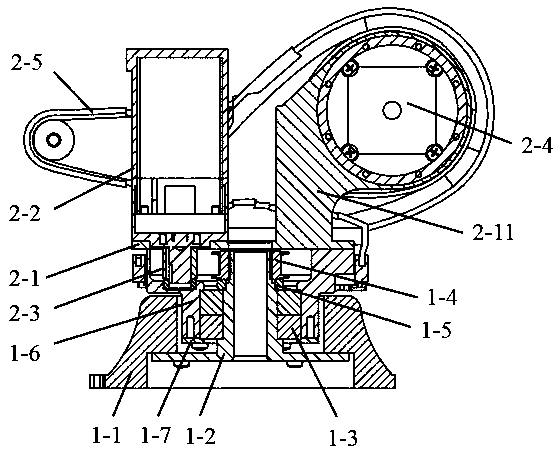

Six-axis light collaborative robot

A robotic and lightweight technology, applied in the field of robotics, can solve the problems of uneconomical use of teaching and research, less freedom, high price, etc., and achieve the effect of facilitating large-scale production and application, reducing unbalanced force, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments. Please note that the embodiments described below are exemplary and are only used to explain the present invention, but should not be construed as limiting the present invention. Where specific techniques or conditions are not indicated in the embodiments, the procedures shall be carried out in accordance with the techniques or conditions described in the literature in the field or in accordance with the product specification.

[0037] In the description of the present invention, it should be understood that the terms "first" and "second" are only used for description purposes, and cannot be understood as indicating or implying relative importance or implicitly indicating the number of indicated technical features. Thus, the features defined with "first" an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com