Microorganism-plant combined mineralized refuse remediation method and system

A technology of mineralized garbage and repair method, applied in the restoration of polluted soil, etc., can solve the problems of high soil texture requirements, secondary pollution, secondary pollution of eluent, etc., and achieve low cost, easy operation, and soil Effects with low texture requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

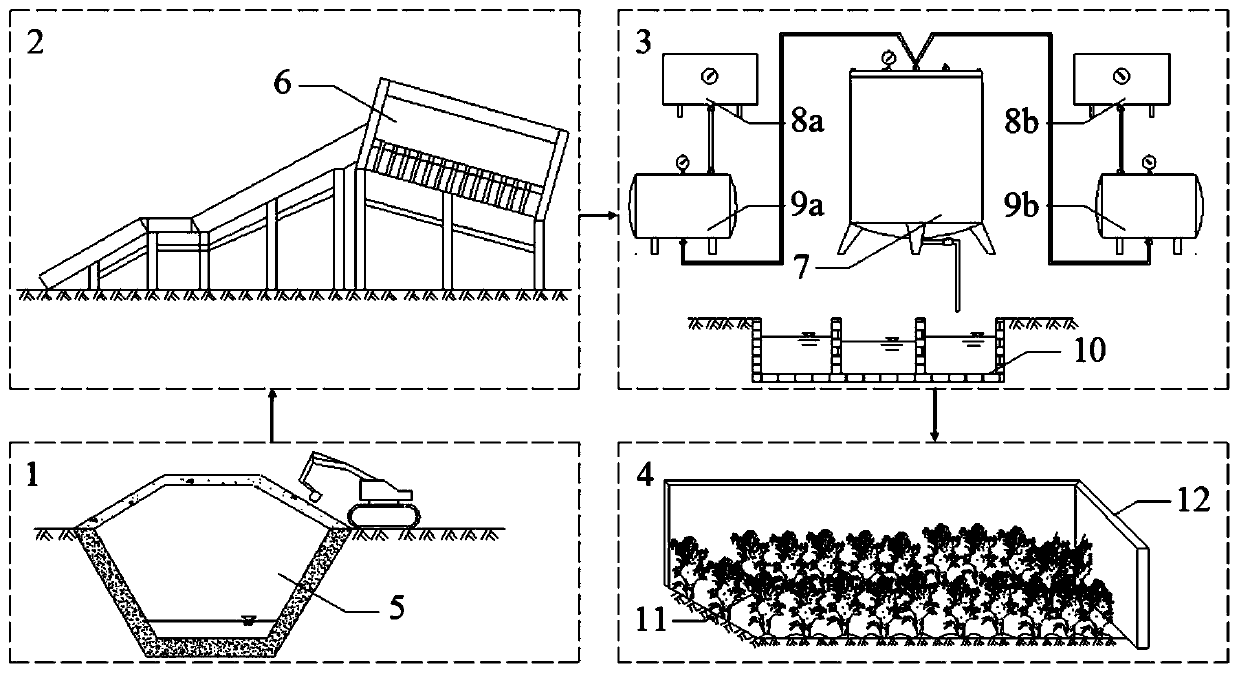

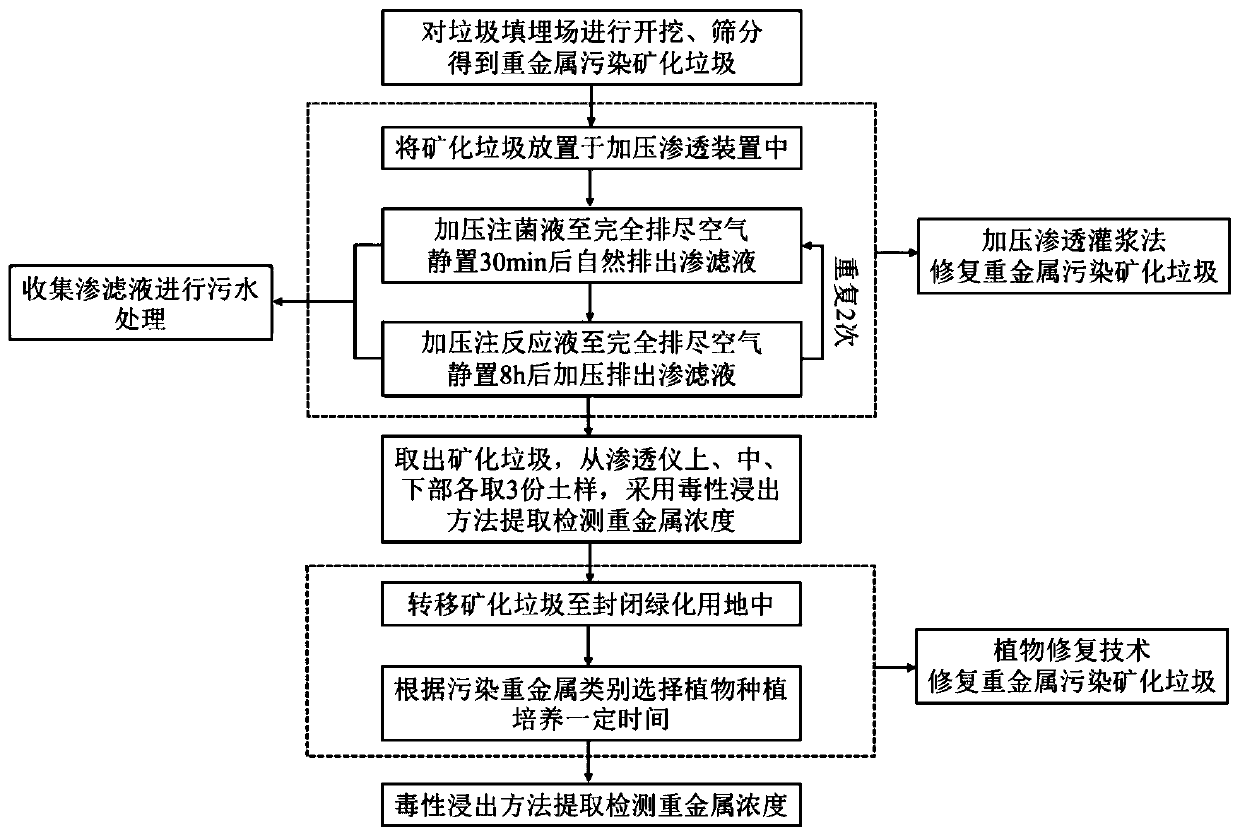

[0048] Restoration of mineralized waste in a landfill that has been closed for 10 years includes the following steps:

[0049] (1) Use the empirical method to excavate the mineralized waste in the landfill, and use the screening machine to screen the heavy metal-contaminated mineralized waste.

[0050] (2) Cultivate Bacillus Pasteurella, mother bacteria solution and nutrient solution (20g / L yeast extract, 10g / L ammonium chloride, 10mg / L manganese sulfate monohydrate, 24mg / L nickel chloride hexahydrate, 1mol / L Sodium hydroxide solution to adjust the pH to 8.5) mixed at a ratio of 1:100, cultured at 30°C and 160rpm for 24h, the OD of the bacterial solution 600 1.0; prepare a mixed reaction solution of urea and calcium chloride with a concentration of 1mol / L.

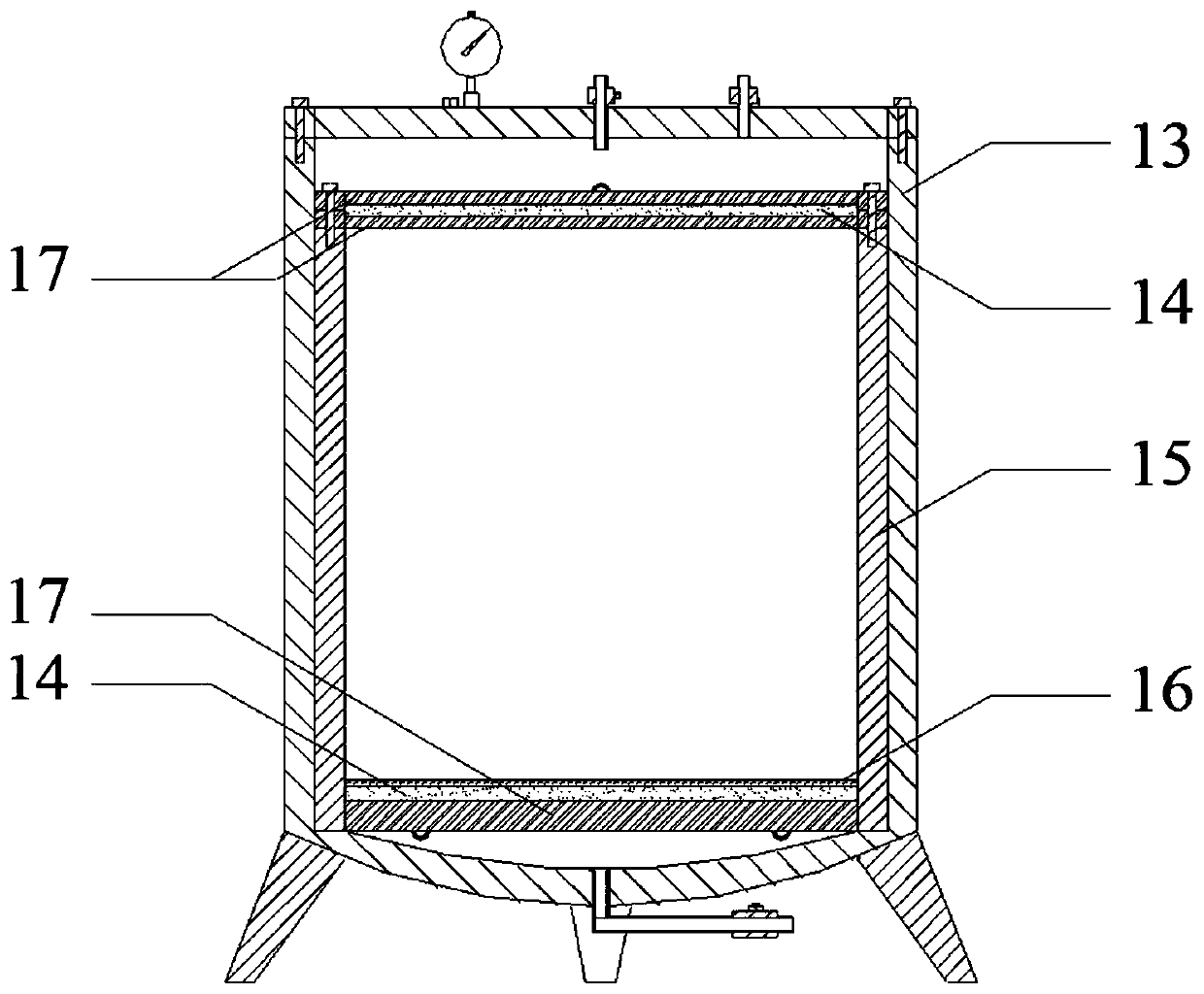

[0051] (3) Put the heavy metal polluted mineralized waste into the infiltration irrigation device, and place the mineralized waste in a natural stack, and level it properly when the soil sample is close to the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com