Coalbed methane mining filtration treatment equipment

A technology for processing equipment and coalbed methane, which is applied in the fields of filtration of dispersed particles, separation methods, separation of dispersed particles, etc., can solve the problems of affecting mining efficiency, insufficient filtration, and coal dust deposition, etc., so as to improve gas activity and improve filtration efficiency. , the effect of reducing liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

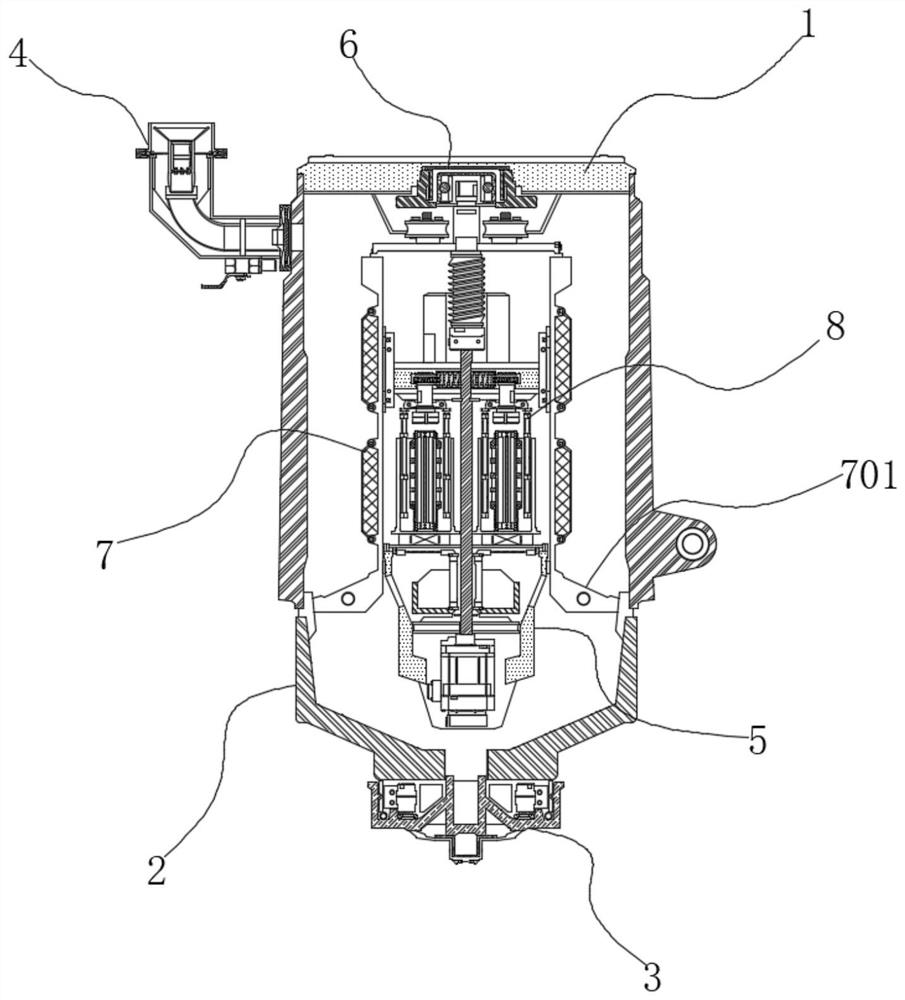

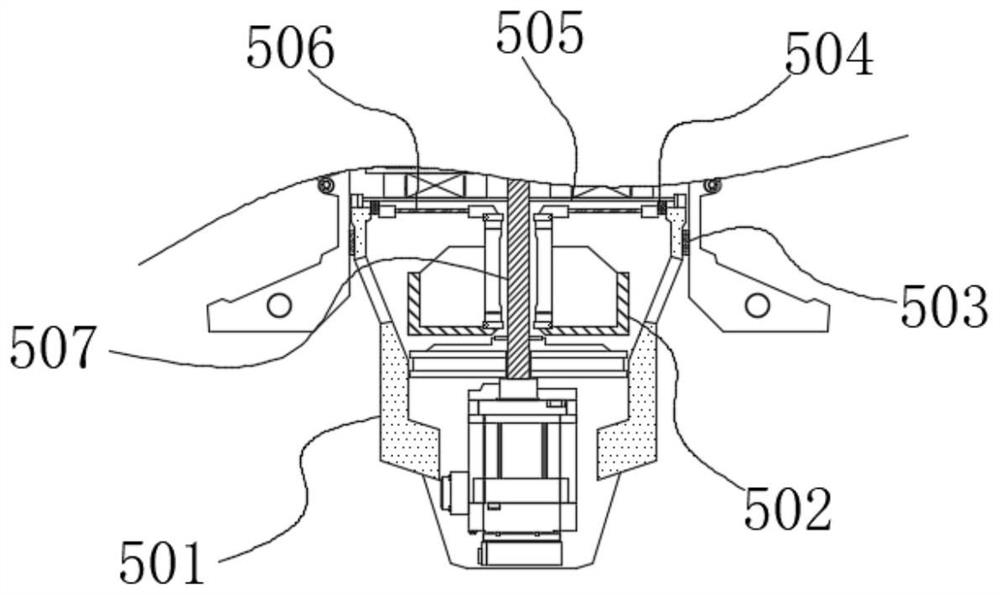

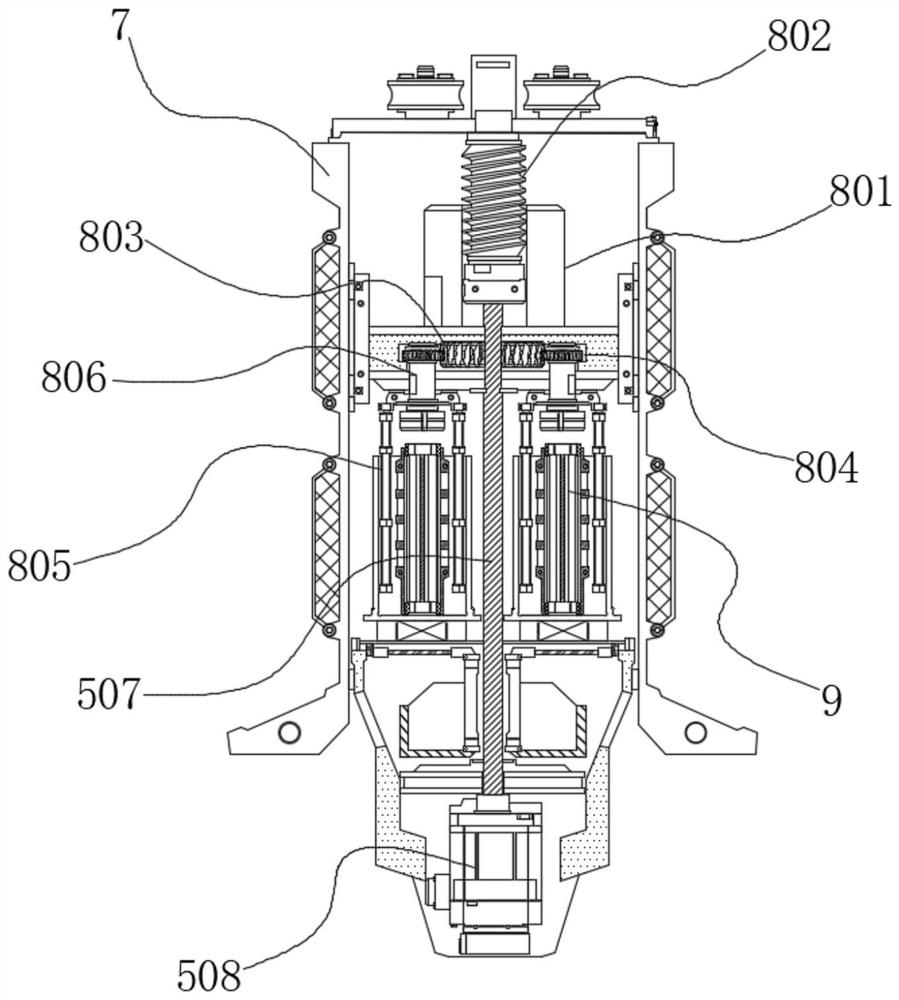

[0019] refer to figure 1 , the present invention provides a technical solution: coalbed methane mining filtration treatment equipment, including a treatment box 1, a lower end cover 3, a sealing cover 2, an exhaust device 4 and an inner filter cartridge 7, the lower end surface of the treatment box 1 Bolts are fixed with a sealing cover 2, the air inlet end of the sealing cover 2 is equipped with a lower end cover 3, and the air intake is sealed through the lower end cover 3, and an inner The filter cartridge 7, the inner filter cartridge 7 is fixed to the treatment box 1 through the connecting brackets 701 on both sides of the outside, and the outside of the treatment box 1 is connected with an exhaust device 4, and the filtered coalbed methane is effectively Absorption and discharge, the inner filter cartridge 7 is provided with a primary dust collection assembly 5, a drainage assembly 8 and a fine filter assembly 9, and the primary dust collection assembly 5 performs prelim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com