Raman fiber laser

A Raman fiber and Raman laser technology, applied in the field of fiber and laser, can solve the problems of large system, low conversion efficiency and small gain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

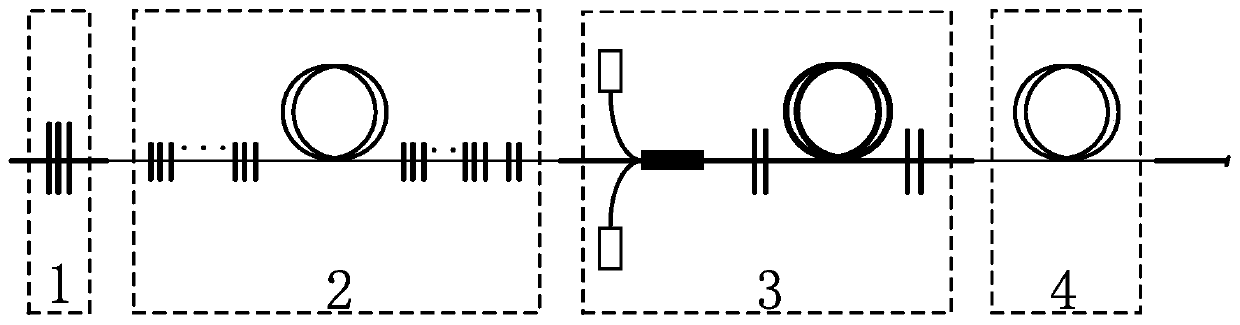

[0020] The invention provides a Raman fiber laser, such as figure 1 As shown, the laser has a simple structure and high conversion efficiency.

[0021] Such as figure 1 The Raman fiber laser shown includes a highly reflective fiber grating 1 , a Raman laser seed source 2 , a fiber laser pump source 3 and a Raman laser amplifier 4 connected in sequence.

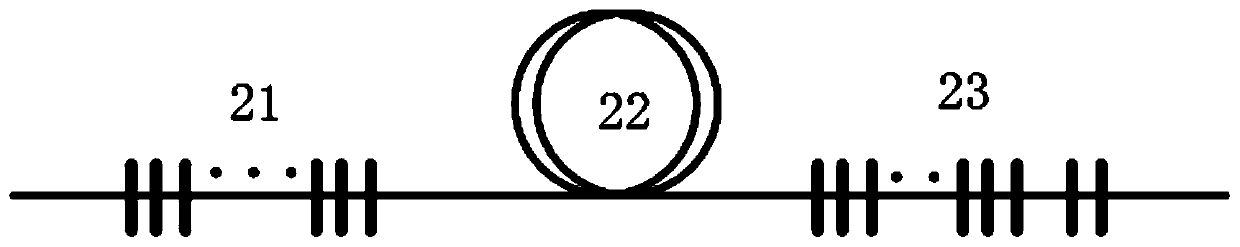

[0022] Such as figure 2 As shown, the Raman laser seed source 2 includes a reflective-end cascaded grating string 21 , a Raman gain fiber 22 and an output-end cascaded grating string 23 connected in sequence, and the reflective-end cascaded grating string 21 is connected to the high-reflection fiber grating 1 .

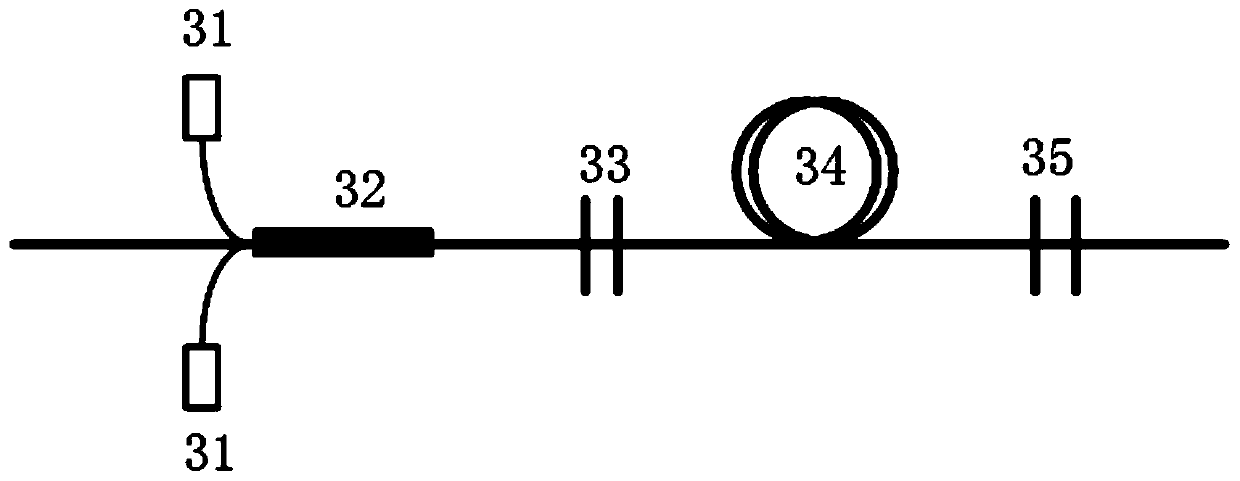

[0023] Such as image 3 As shown, the fiber laser pump source 3 includes a semiconductor pump laser 31, a fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com