Drainage system and drainage method during tunnel operation period

A drainage system and tunnel technology, applied in drainage, earthwork drilling, pump components, etc., can solve problems such as drainage of surrounding rock water in tunnels, water leakage in tunnels, interruption of siphon process, etc., to avoid vacuum failure, reduce operating costs, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

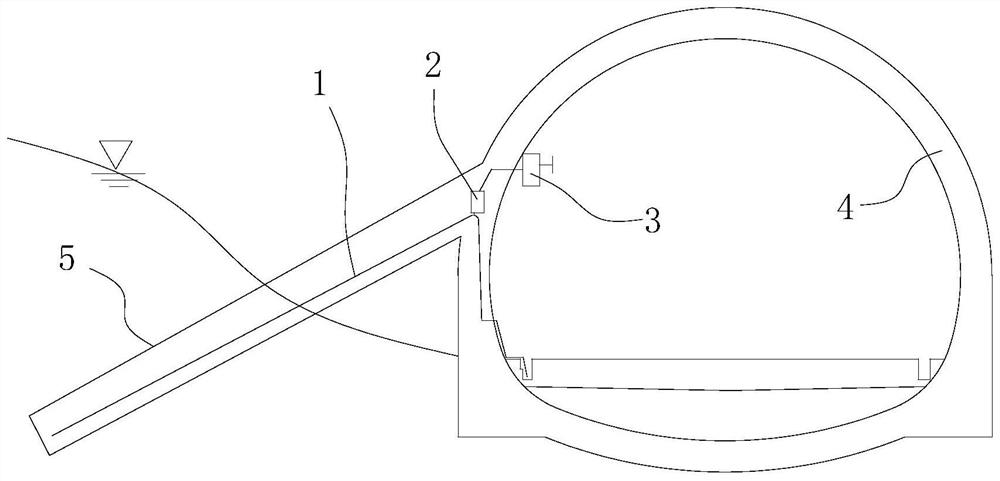

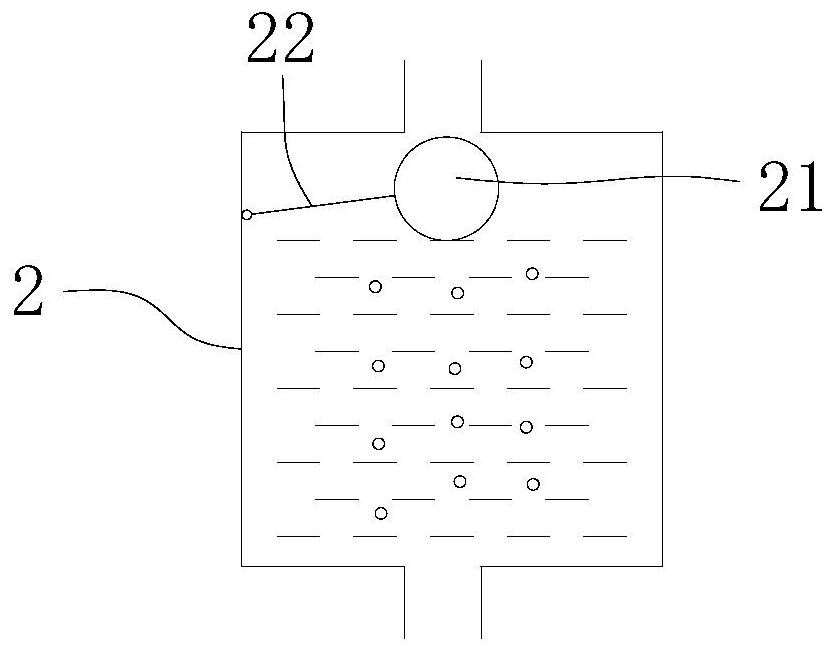

[0031] like figure 1 , figure 2 As shown, the drainage system of the tunnel operation period of the embodiment of the present invention includes a siphon pipe 1; it also includes an air collection box 2 and a wind power mechanism 3; the bottom of the air collection box 2 communicates with the highest point of the siphon pipe 1 through a connecting pipe;

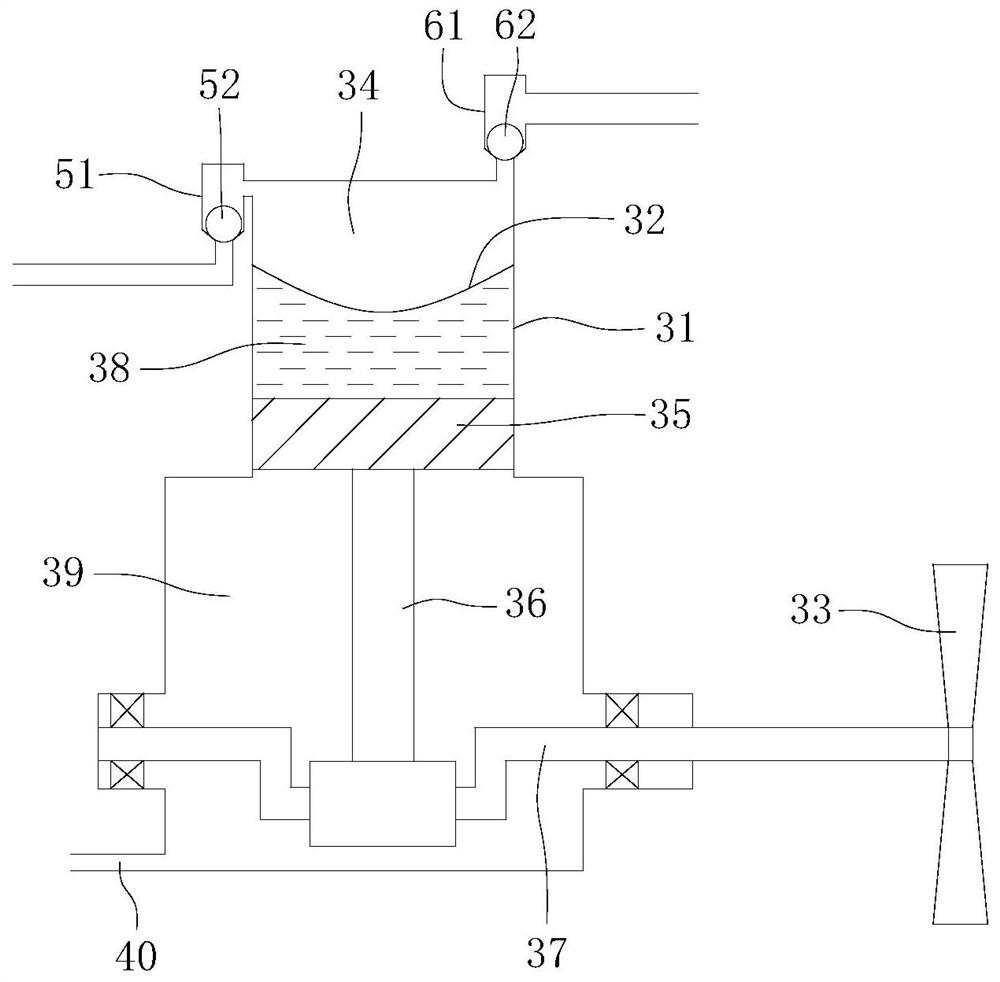

[0032] The wind power mechanism 3 includes an exhaust box 31, a diaphragm 32, a fan blade 33, a first one-way communication mechanism and a second one-way communication mechanism; the diaphragm 32 is arranged in the exhaust box 31, and the edge of the diaphragm 32 It is sealingly connected with the inner wall of the exhaust box 31, and div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com