Multiple parking garage

A parking garage, duplex technology, applied in the field of parking garages, can solve the problems of energy consumption and land resources, difficult parking, complicated electric or mechanical parking equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

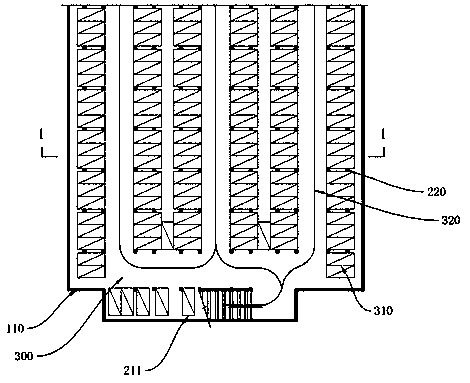

[0032] see Figure 1-Figure 5 , a compound parking garage, comprising a first stack and at least one second stack, the first stack is located on the uppermost floor of the garage, the second stack is located below the first stack, and can be based on It is necessary to arrange multiple layers of second laminated layers downwards in order to form a multi-layered garage. Such as Figure 4 , the second stack has two layers. Figure 5 The second stack has three layers, and so on.

[0033] The first stack and the first and second stacks below it are communicated through the first ramp 211, and the entry and exit of the car 520 between the first stack and the second stack can be realized through the first ramp 211;

[0034] The second stack is communicated with the first and second stacks below it through the second ramp 212, and the second ramp 212 enables the car 520 to enter and exit between the adjacent second stacks on the upper and lower floors;

[0035] The whole garage i...

Embodiment 2

[0052] see Figure 6-Figure 8 , the difference from Embodiment 1 is that its width is increased. At this time, at least one strip-shaped opening can be set on the laminated board 300, thereby forming at least one hollow 110, plus the two sides of the laminated board 300 and the outer wall 100 forms at least one hollow 110, at this time, there are at least two hollows 110 in the parking garage. This design is mainly selected according to the actual ventilation, smoke exhaust, and garage size.

Embodiment 3

[0054] This duplex parking garage also can take the form on the ground, and needn't be buried in the ground, when taking the form on the ground, there is no covering soil on the top plate, and there is no outer wall to close around.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com