System and method for culturing probiotics

A probiotics and mixing cylinder technology, applied in the system field of probiotics culture, can solve the problems of inconvenient wall scraping and mixing, poor mixing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

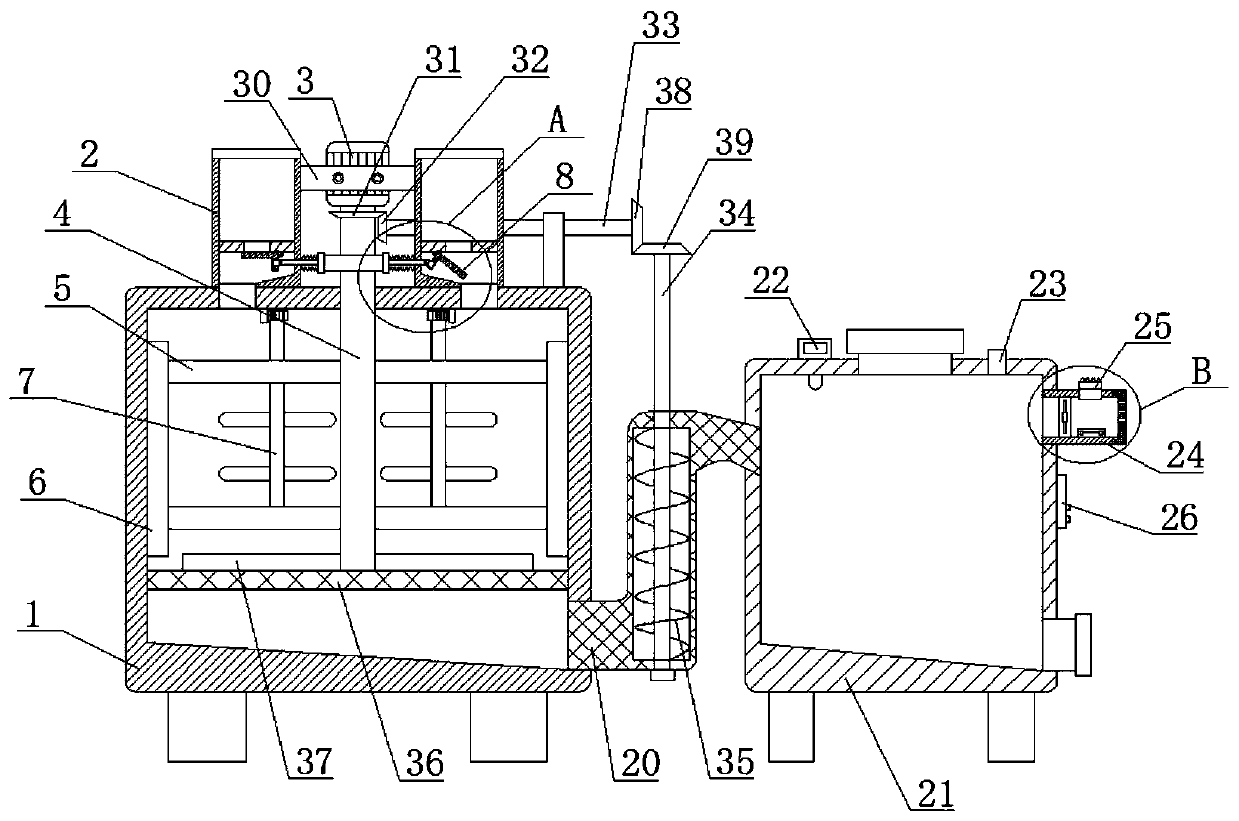

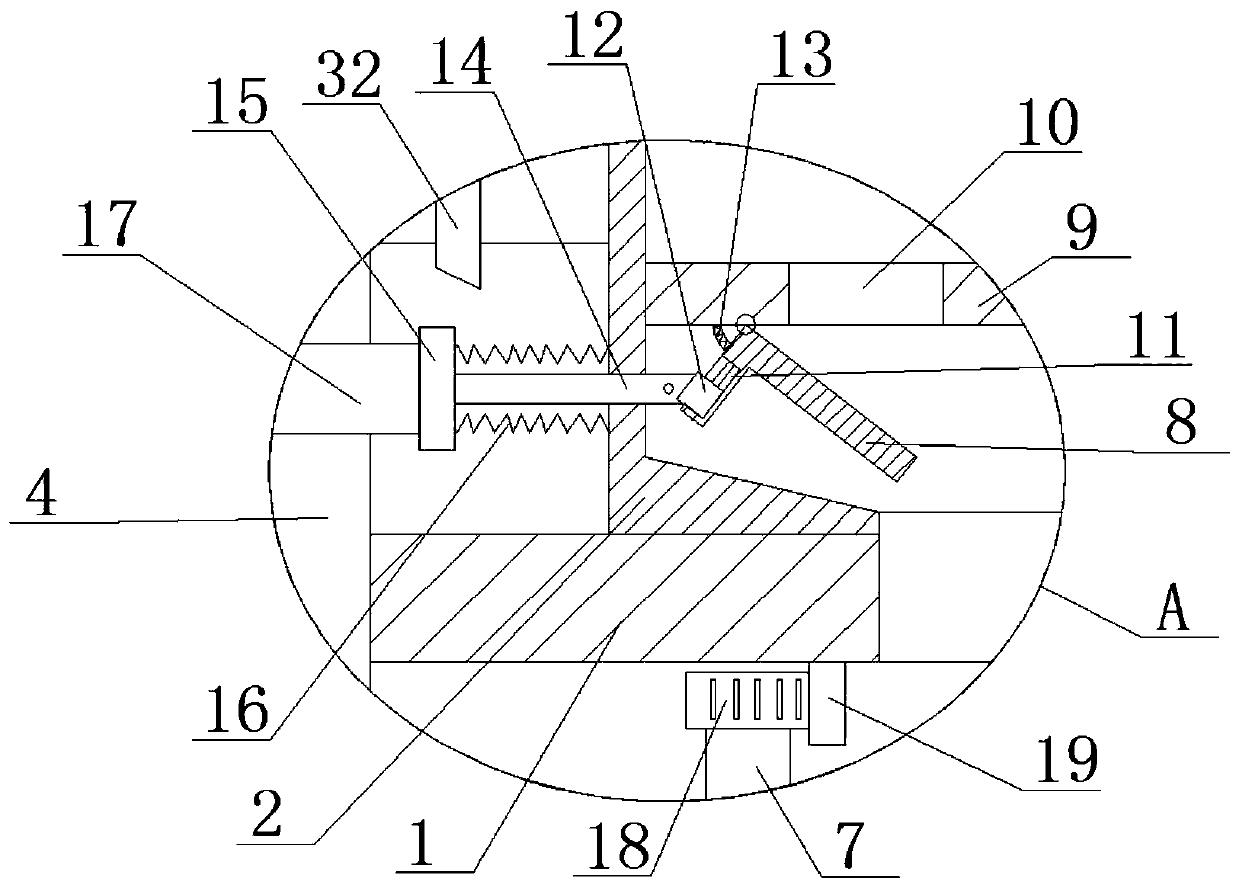

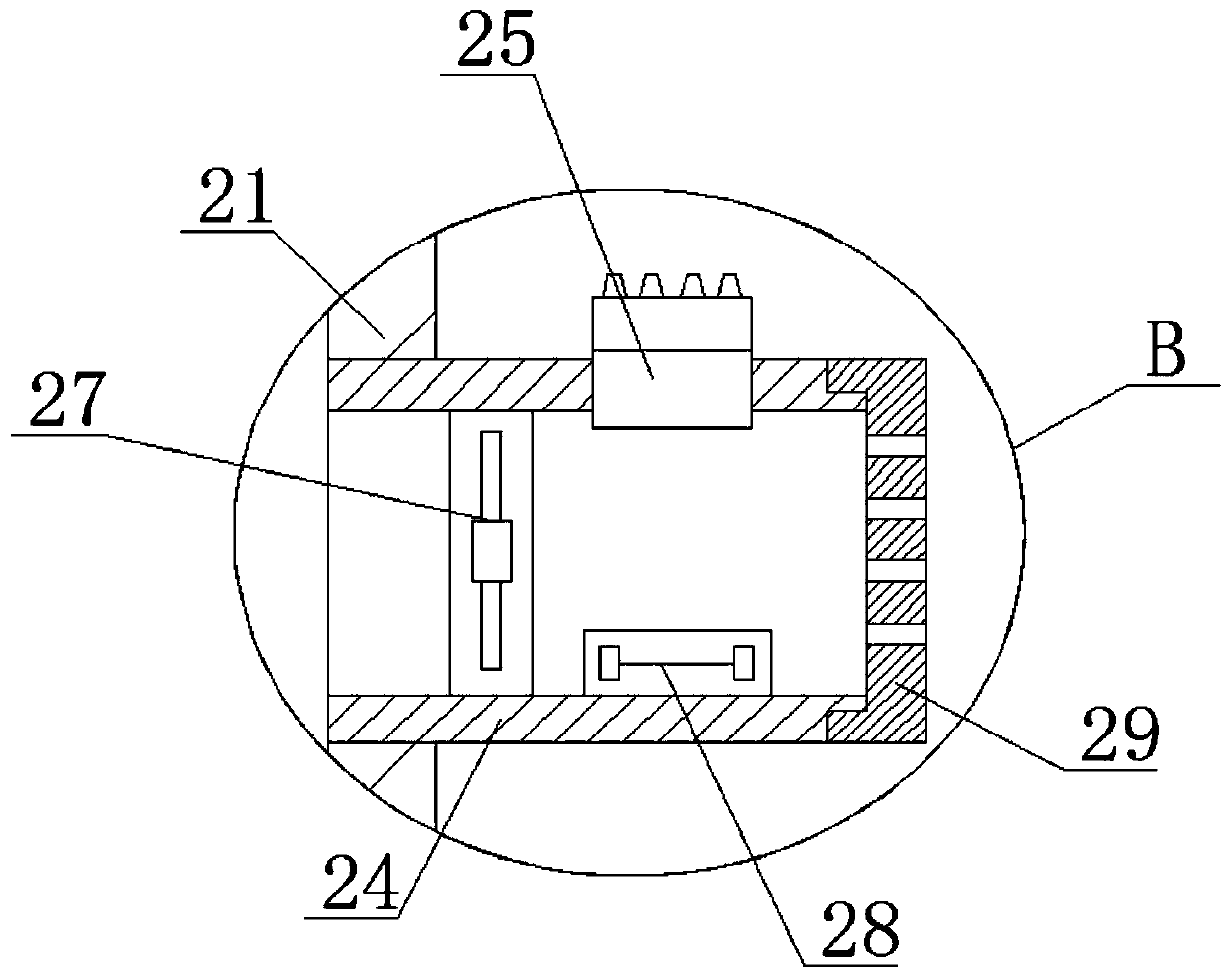

[0035] refer to Figure 1-5, a system for cultivating probiotics, comprising a mixing cylinder 1 and a fermenter 21, the same feeding mechanism is arranged between the mixing cylinder 1 and the fermenting tank 21, the mixing cylinder 1 is provided with a feeding mechanism and a mixing mechanism, and the fermentation The tank 21 is provided with a temperature monitoring mechanism and a sterilization mechanism. The feeding mechanism includes a plurality of feeding barrels 2. The mixing mechanism includes a motor 3 and a column shaft 4. The column shaft 4 is rotationally connected with the mixing barrel 1. The multiple feeding barrels 2 are connected to the mixing barrel 2. The cylinders 1 are connected, and the same connection shell 30 is fixedly installed between multiple feeding cylinders 2, the motor 3 is fixedly connected to the connection shell 30, the output shaft of the motor 3 is fixedly connected to the column shaft 4, and the outer side of the column shaft 4 is symmetri...

Embodiment 2

[0049] refer to Figure 1-5 , a system for cultivating probiotics, comprising a mixing cylinder 1 and a fermenter 21, the same feeding mechanism is arranged between the mixing cylinder 1 and the fermenting tank 21, the mixing cylinder 1 is provided with a feeding mechanism and a mixing mechanism, and the fermentation The tank 21 is provided with a temperature monitoring mechanism and a sterilization mechanism. The feeding mechanism includes a plurality of feeding barrels 2. The mixing mechanism includes a motor 3 and a column shaft 4. The column shaft 4 is rotationally connected with the mixing barrel 1. The multiple feeding barrels 2 are connected to the mixing barrel 2. The cylinders 1 are connected, and the same connecting shell 30 is fixedly installed by welding between multiple feeding cylinders 2. The motor 3 and the connecting shell 30 are fixedly connected by screws, and the output shaft of the motor 3 is fixedly connected with the column shaft 4 by screws. The outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com