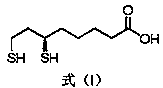

Preparation method of R-(+)-dihydrolipoic acid

A technology of dihydrolipoic acid and lipoic acid, applied in the direction of mercaptan preparation, organic chemical method, organic chemistry, etc., to achieve the effect of promotion in the field of biomedicine, simple preparation method, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 100.0g R-lipoic acid, 3.0g 10% Pd / C, 200.0g methanol to a reaction flask, start stirring after adding, and start slowly adding 25% sodium hydroxide solution to adjust the pH of the mixed system to 7- 8. Then pass in nitrogen to replace the air in the reaction system 3 times, and then pass in hydrogen to replace the nitrogen in the system 3 times, and then control the reaction system at 27-32°C until the end of the reaction, filter, and use 10.0g for the filter cake After washing with methanol, drain off, and collect the filtrate.

[0025] Place the filtrate obtained above in a suitable reactor, start stirring, and start slowly adding concentrated hydrochloric acid to adjust the pH to 5.0-6.5, then add 8.0g activated carbon and 5.0g diatomaceous earth, keep at room temperature and stir for 1 hour. After filtration, the filter cake was washed with 10.0 g methanol, the filtrate was collected, and the solvent was removed from the filtrate under reduced pressure to obtain c...

Embodiment 2

[0028] Add 100.0g R-lipoic acid, 3.0g Raney nickel, and 200.0g methanol to a reaction flask. After the addition, start stirring and start slowly adding 25% sodium hydroxide solution to adjust the pH of the mixed system to 7-8. Then pass in nitrogen to replace the air in the reaction system 3 times, and then pass in hydrogen to replace the nitrogen in the system 3 times, then control the reaction system at 27-32°C until the end of the reaction, filter, and wash the filter cake with 10.0g methanol After draining, collect the filtrate.

[0029] Place the filtrate obtained above in a suitable reactor, start stirring, and start slowly adding concentrated hydrochloric acid to adjust the pH to 5.0-6.5, then add 8.0g activated carbon and 5.0g diatomaceous earth, keep at room temperature and stir for 1 hour. After filtration, the filter cake was washed with 10.0 g methanol, the filtrate was collected, and the solvent was removed from the filtrate under reduced pressure to obtain crude R-(...

Embodiment 3

[0032] Add 100.0g R-lipoic acid, 3.0g 10% Pd / C, 200.0g ethanol to a reaction flask, start stirring after adding, and start slowly adding 25% sodium hydroxide solution to adjust the pH value of the mixed system to 7- 8. Then pass in nitrogen to replace the air in the reaction system 3 times, and then pass in hydrogen to replace the nitrogen in the system 3 times, and then control the reaction system at 27-32°C until the end of the reaction, filter, and use 10.0g for the filter cake After washing with ethanol, drain it and collect the filtrate.

[0033] Place the filtrate obtained above in a suitable reactor, start stirring, and start slowly adding concentrated hydrochloric acid to adjust the pH to 5.0-6.5, then add 8.0g activated carbon and 5.0g diatomaceous earth, keep at room temperature and stir for 1 hour. After filtering, the filter cake was washed with 10.0 g of ethanol, the filtrate was collected, and the filtrate was decompressed to remove the solvent to obtain crude R-(+)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com