An overweight horizontal high-pressure heater hoisting system and hoisting method

A technology of high-pressure heater and hoisting method, which is applied in the direction of track system, hoisting device, lifting device, etc., to achieve the effect of solving instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

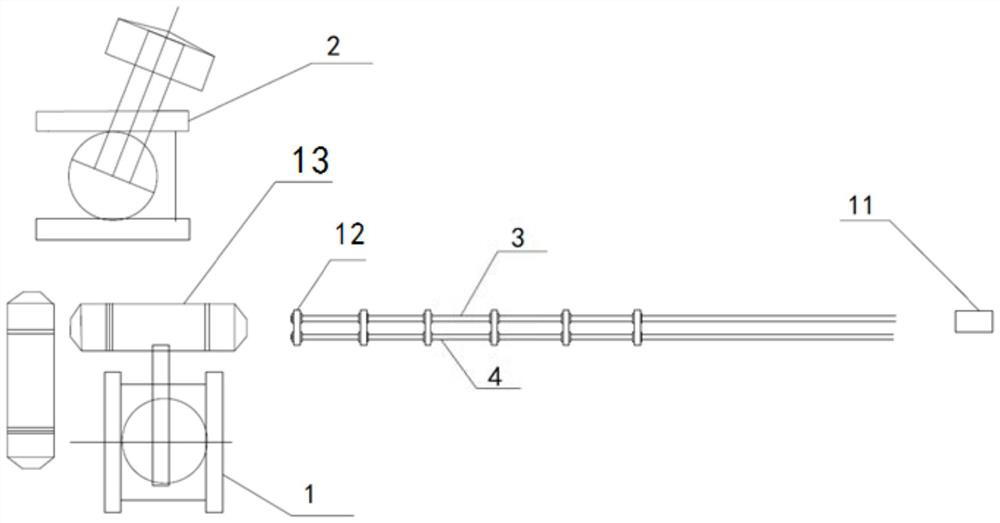

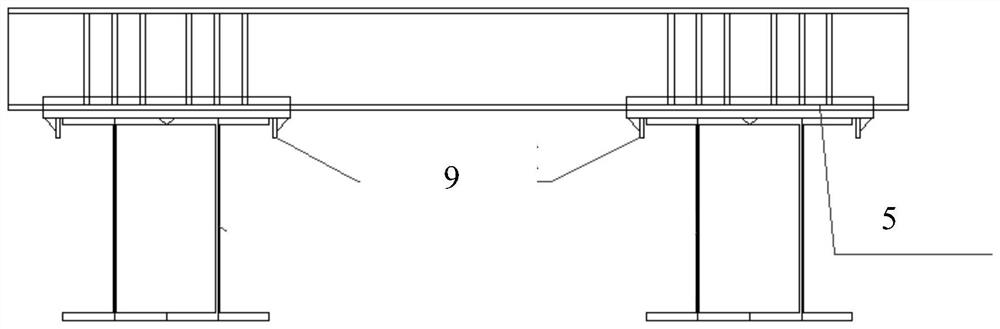

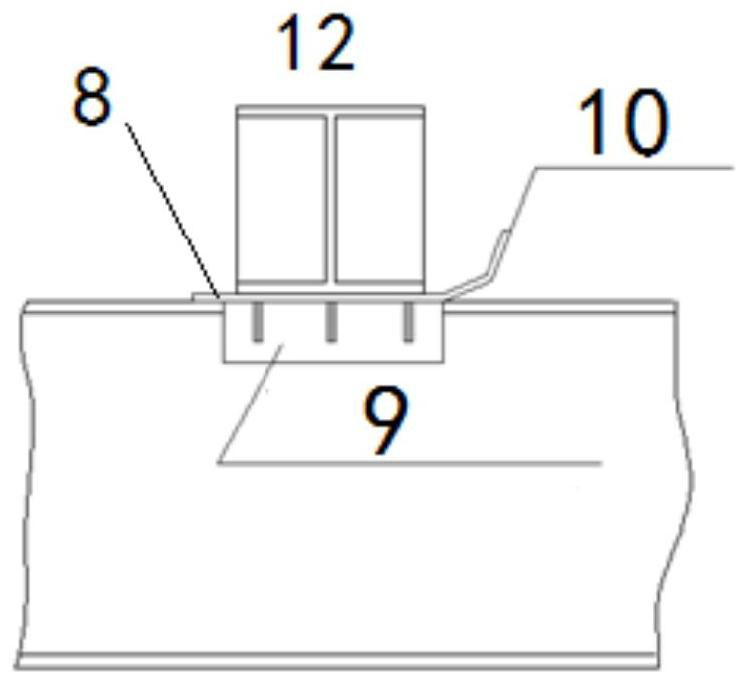

[0047] The object to be lifted (overweight horizontal equipment) is an overweight horizontal high-pressure heater 13 with a weight of 320 tons.

[0048] According to the designed overweight horizontal high-pressure heater 13 hoisting and in-position plan, complete the installation of hauling slides, traction facilities and the arrangement of two hoisting machines, and determine the overweight horizontal high-pressure heater before the overweight horizontal high-pressure heater 13 enters the site. The loading direction of the heater 13 should be consistent with the plan. After the overweight horizontal high-pressure heater 13, park the transport truck to the unloading position, and use a 600-ton crawler crane and a 450-ton crawler crane to lift the unloading truck; for the convenience of equipment transportation, the manufacturer will The overweight horizontal high-pressure heater 13 arrives at an angle. After unloading, the high-pressure heater needs to be turned around. A 600-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com